Dry dust removal and wet desulphurization integral efficient smoke gas purification device

A technology of flue gas purification and dry dust removal, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, which can solve the problems of incomplete dust removal, inability to lift dust, and influence on desulfurization effect of wet dust collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

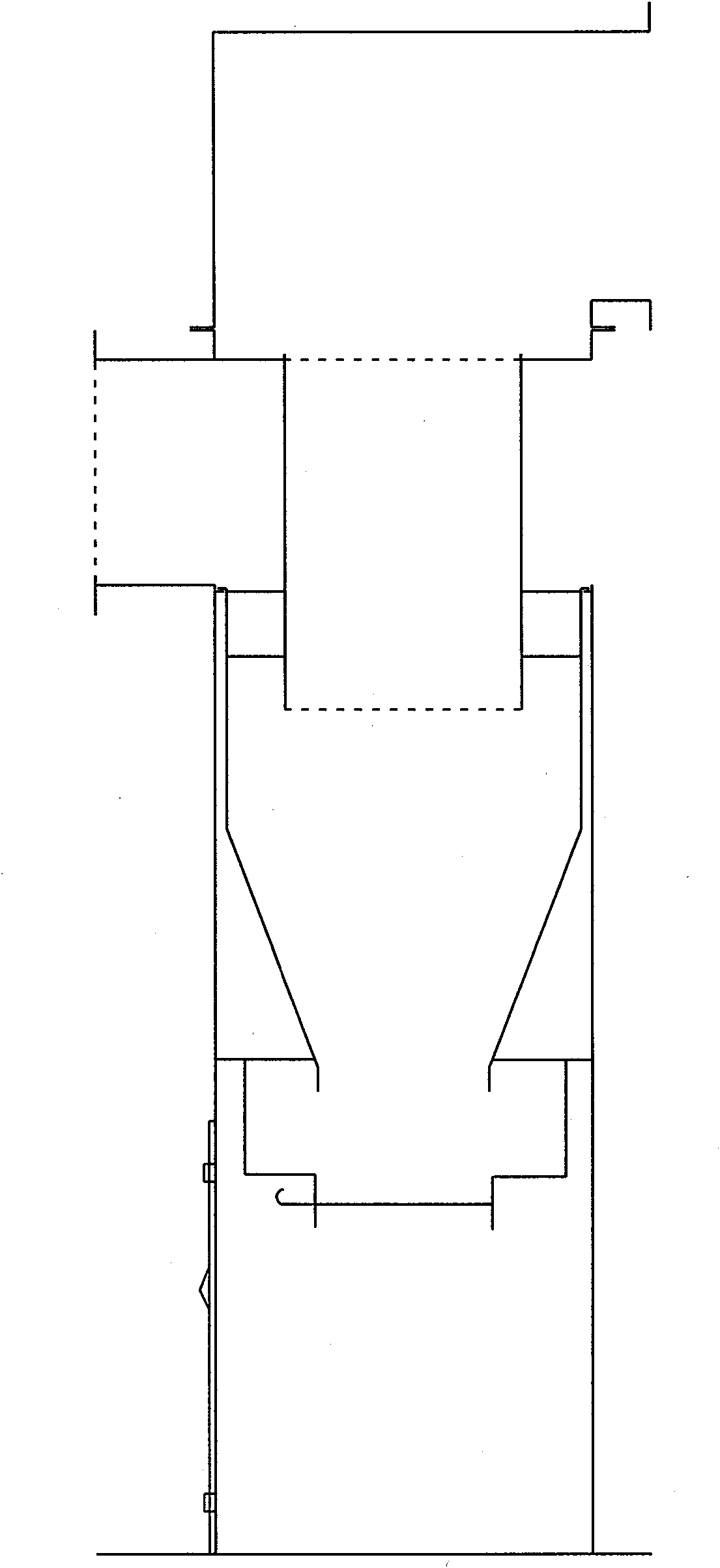

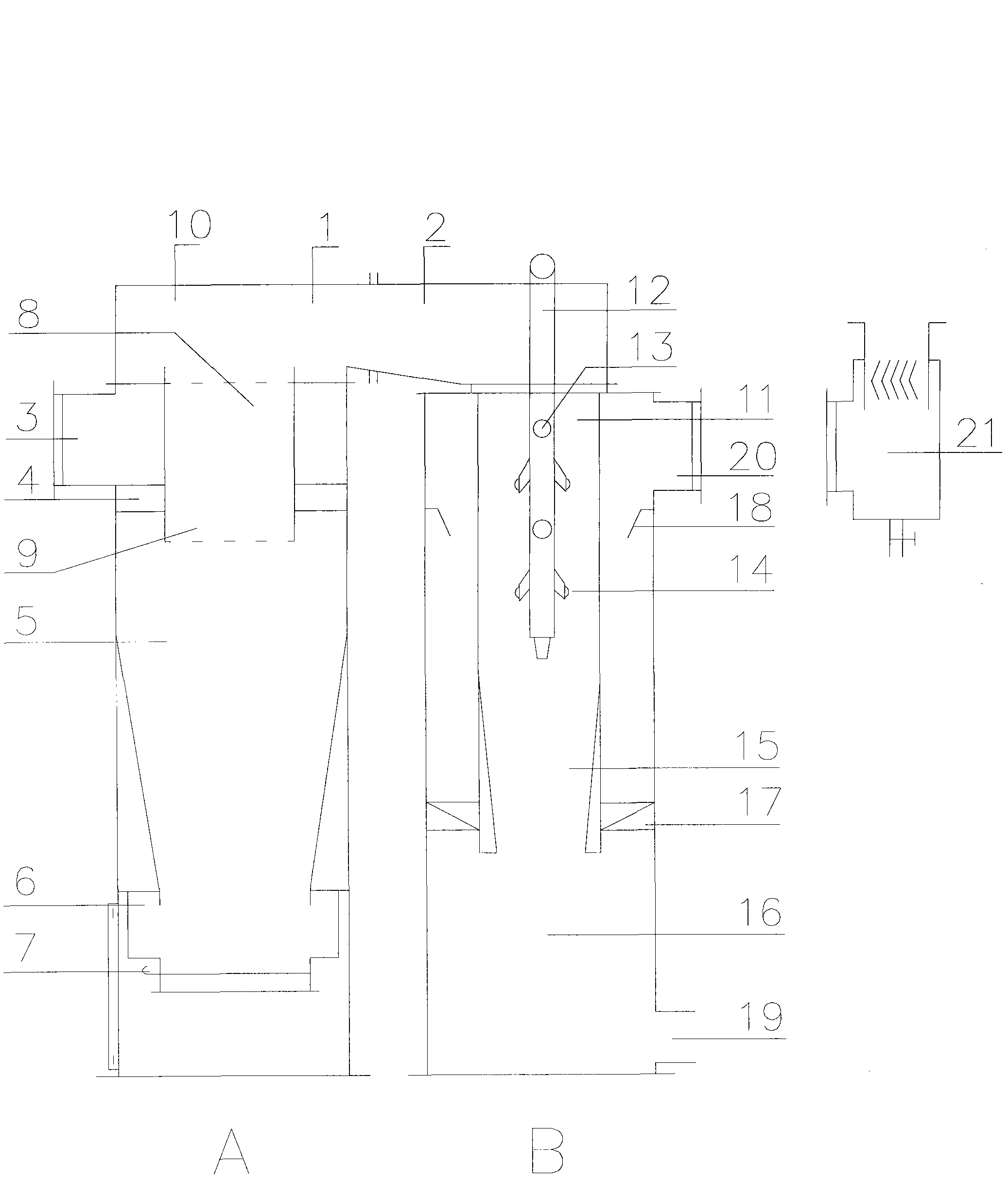

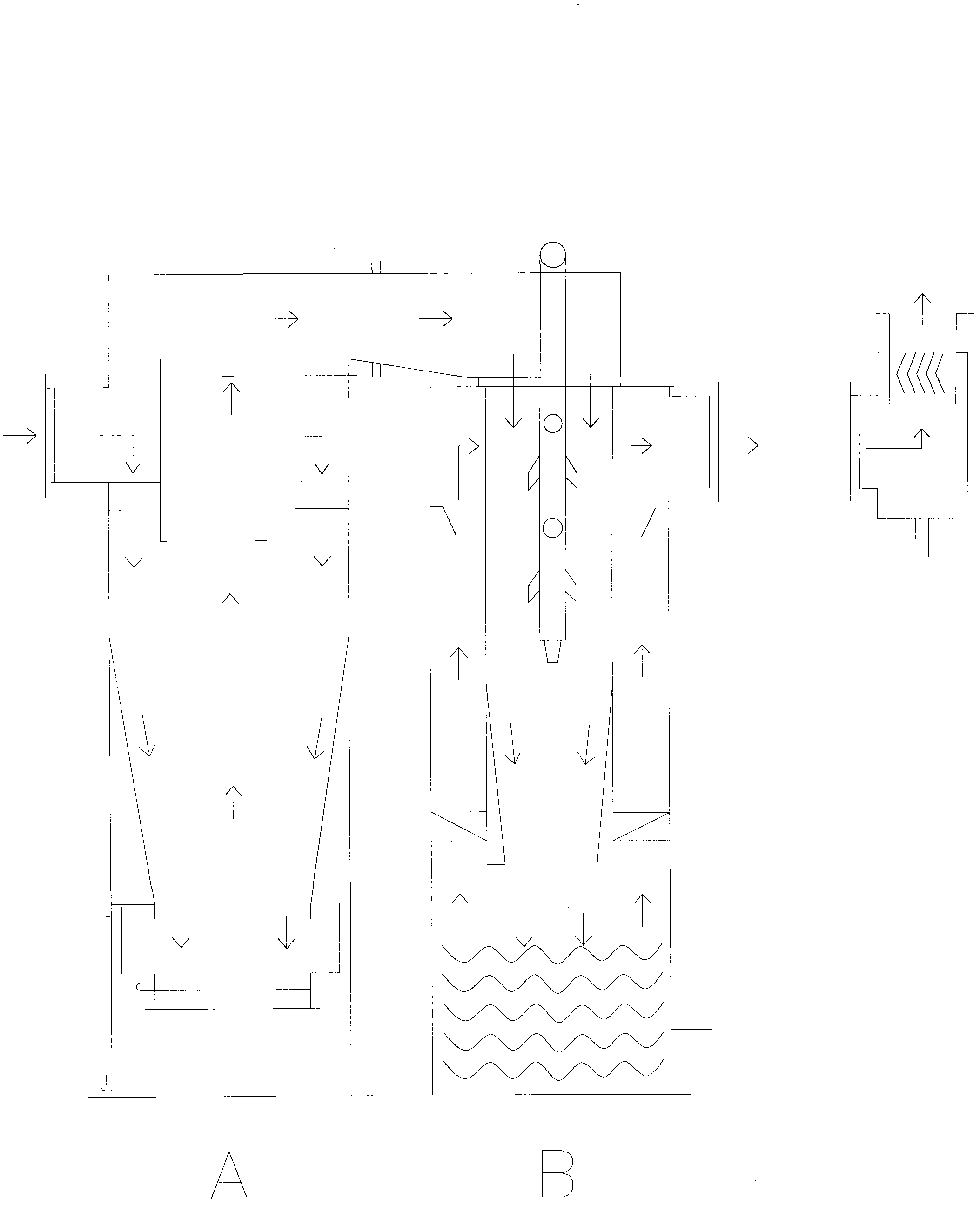

[0014] Dry dust removal and wet desulfurization integrated high-efficiency flue gas purification device, which consists of an advanced dry dust collector in the A tube and the Venturi desulfurization tower with the highest efficiency in the B tower. The smoke outlet (1) of the dry dust collector is connected with the smoke inlet (2) of the wet desulfurization tower to form a whole. Boiler and kiln flue gas enters from the smoke inlet (3) of cylinder A, and enters the flue gas settling chamber (5) through the deflector (4) using the cyclone principle, and the dust slowly falls from the settling chamber into the ash by gravity In the bucket (6), the dust is discharged from the stretch door (7) into the ash bag, and the flue gas after dust removal rises due to the action of the induced draft fan, and enters the inner core barrel (8) through the swirl plate (9) to the flue gas chamber (10), from the smoke outlet of the dry dust collector (1) to the smoke inlet of the wet desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com