Wet-type ammonia process flue gas purifying technique for jointly removing multipollutant and system thereof

A technology for combined removal and pollutant removal, applied in the field of flue gas purification and treatment, can solve the problems of ineffective removal, low investment and operating costs, and high quality requirements for desulfurizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

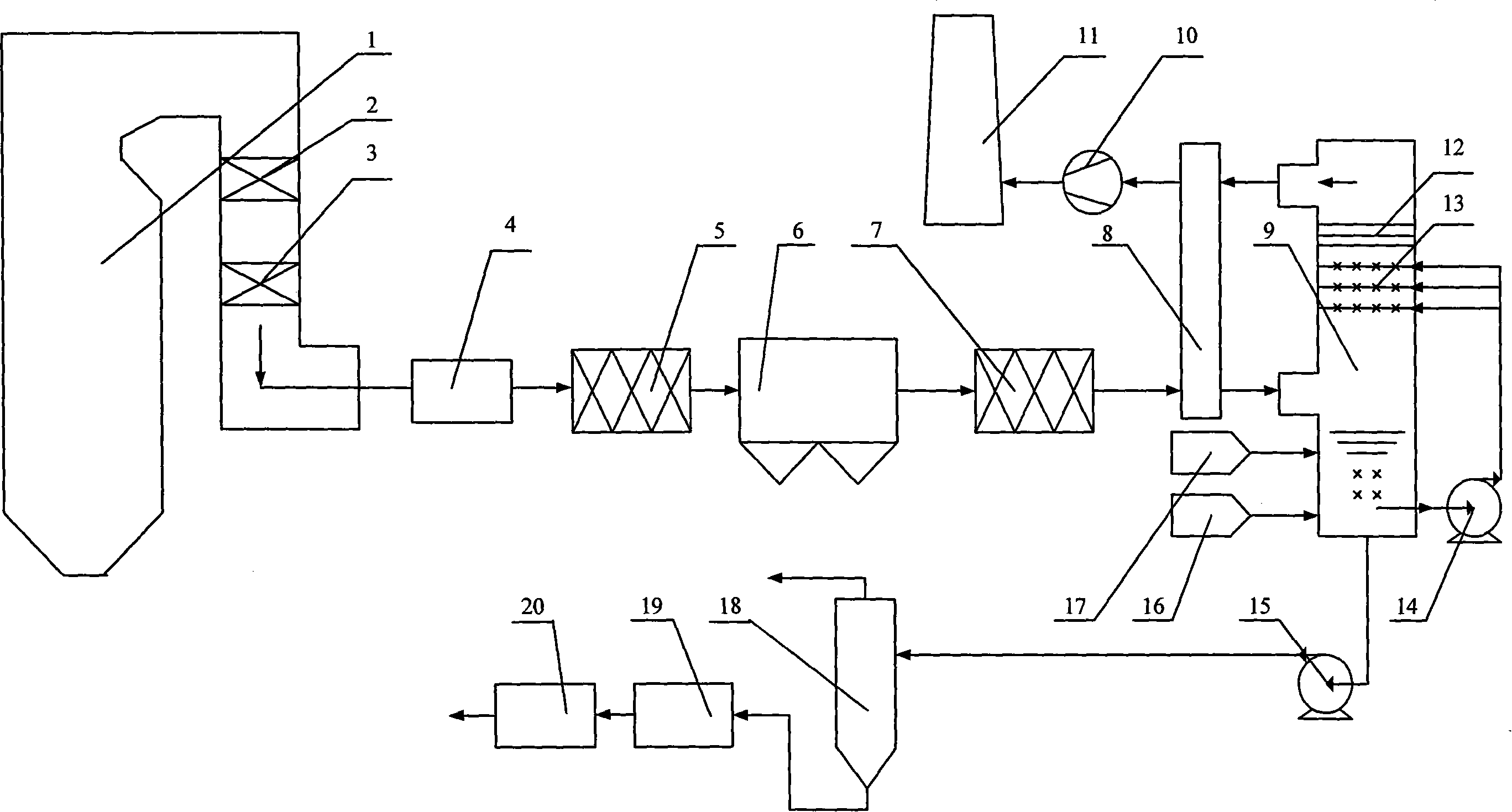

[0046] Below for a coal-fired boiler unit, in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0047] The wet ammonia method flue gas cleaning system shown in the figure is composed of a high gradient magnetic field generator 4, a particle agglomeration accelerator injection device 5, an electrostatic precipitator 6 and its connecting flue, etc. Particle agglomeration and removal system; the nitric oxide oxidation system is composed of the oxidant injection device 7 and its connected flue; it consists of flue gas heat exchanger 8, reaction absorption tower 9, induced draft fan 10, chimney 11 and other equipment and its connected flue A desulfurization and denitrification system is formed; a desulfurization and denitrification by-product treatment system is composed of cyclone separator 18, dehydrator 19, dryer 20 and other equipment and their connecting pipes.

[0048] The high-gradient magnetic field generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com