Method for preparing calcium oxide and sulfur by double-atmosphere fluidized roasting of desulfurated gypsum

A desulfurization gypsum, boiling roasting technology, applied in the preparation/purification of sulfur, calcium/strontium/barium oxide/hydroxide, chemical industry, etc., can solve the problem of low comprehensive utilization rate of desulfurization gypsum, and achieve rich coal raw materials , easy to operate, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

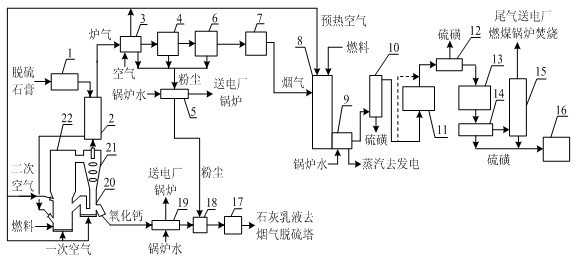

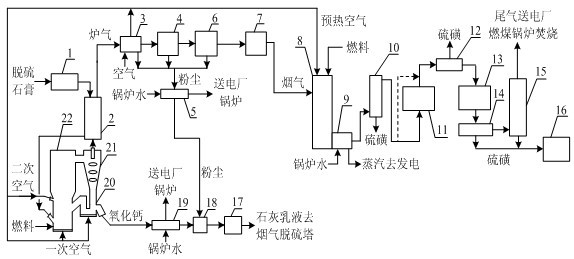

[0036] Example 1. Taking a production line with a processing capacity of 100,000 tons / year of desulfurized gypsum (dry basis) as an example, the following figure 1 process flow. 12.5t / h of desulfurized gypsum (dry basis) into the circulating fluidized bed decomposition furnace, the temperature is 600°C, and the air volume into the furnace is 9500m 3 / h, temperature 250°C, primary air volume 7600m 3 / h, secondary air volume 1900m 3 / h (secondary air accounts for 20% of the total air volume). The temperature of the gas exiting the calciner is 1200°C, the decomposition rate of gypsum is 99.3%, and the composition of the furnace gas is SO 2 Volume fraction 12.4%, O 2 Volume fraction 1.0%, CO 2 Volume fraction 10.3%, N 2 The volume fraction is 76.3%. The amount of slag discharged from the calciner is 5.7t / h, of which the mass fraction of CaO is 90.5%, which meets the quality index of calcium oxide for flue gas desulfurization. The reduction combustion furnace uses water ga...

Embodiment 2

[0037] Example 2. Also take a production line with a desulfurization gypsum (dry basis) processing capacity of 100,000 tons per year as an example. figure 1 process flow. 12.5t / h of desulfurized gypsum (dry basis) into the circulating fluidized bed decomposition furnace, the temperature is 700°C, and the air volume into the furnace is 8500m 3 / h, temperature 300°C, primary air volume 7000m 3 / h, secondary air volume 1500m 3 / h (secondary air accounts for 17.6% of the total air volume). The temperature of the gas exiting the calciner is 1000°C, the decomposition rate of gypsum is 99.1%, and the composition of the furnace gas is SO 2 Volume fraction 14.0%, O 2 Volume fraction 1.0%, CO 2 Volume fraction 10.1%, N 2 The volume fraction is 74.9%. The amount of slag discharged from the calciner is 5.65t / h, of which the mass fraction of CaO is 89.5%, which meets the quality index of calcium oxide for flue gas desulfurization. The reduction combustion furnace uses water gas as...

Embodiment 3

[0038] Example 3. Also take a production line with a desulfurization gypsum (dry basis) processing capacity of 100,000 tons per year as an example. figure 1 process flow. 12.5t / h of desulfurized gypsum (dry basis) into the circulating fluidized bed decomposition furnace, the temperature is 700°C, and the air volume into the furnace is 8000m 3 / h, temperature 300°C, primary air volume 6500m 3 / h, secondary air volume 1500m 3 / h (secondary air accounts for 18.75% of the total air volume). The temperature of the gas exiting the calciner is 950°C, the decomposition rate of gypsum is 99%, and the composition of the furnace gas is SO 2 Volume fraction 15.0%, O 2 Volume fraction 1.0%, CO 2 Volume fraction 9.0%, N 2 The volume fraction is 76.0%. The slag discharge of the calciner is 5.6t / h, of which the mass fraction of CaO is 90.0%, which meets the quality index of calcium oxide for flue gas desulfurization. The reduction combustion furnace uses water gas as fuel, the combus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com