Cyclic fluidized bed active coke desulfurating and sulfur reutilization method

A circulating fluidized bed and activated coke technology, applied in chemical instruments and methods, separation methods, preparation/purification of sulfur, etc., can solve the problems of extremely high requirements for equipment manufacturing materials, high price of activated carbon, and increased operation investment, etc., to achieve Low operating cost, considerable economic value, and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

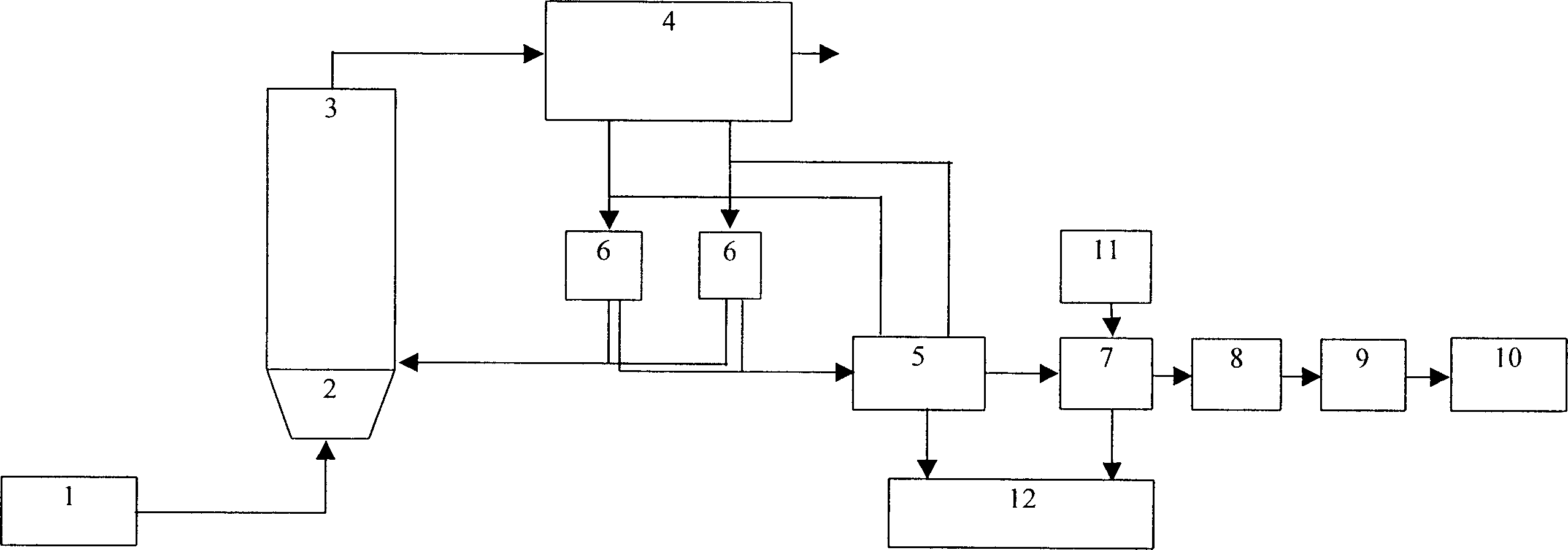

[0040] A power station boiler discharges flue gas of 170,000 cubic meters per hour, and the sulfur content in the flue gas is 2000mg / Nm 3 , The designed diameter of the reactor is 3.9 meters, the height is 20 meters, the volume of the active coke desorption device (3) is 10 cubic meters; the particle size of the selected active coke is about 2.5-7.5mm, and the total circulation is 80 tons. The specific process is:

[0041] The flue gas from the tail of the power plant boiler first enters the pre-dust collector (1), and the flue gas after dust removal enters the reactor (3) through the venturi tube (2), and the active coke is added from the lower part of the desulfurization tower reactor side, and the flue gas and active The coke is fully contacted, the circulation flows, and the SO is removed 2 etc. flue gas and adsorbed SO 2 The activated coke enters the cyclone separator (4), and the flue gas is discharged; the attached SO 2 Active coke enters the active coke adding devic...

Embodiment 2

[0043] A power plant boiler discharges 485,000 cubic meters of flue gas per hour, and the sulfur content in the flue gas is 6,000 mg / Nm 3 , The designed diameter of the reactor is 6.6 meters, the height is 30 meters, the volume of the active coke desorption device (3) is 45 cubic meters; the particle size of the selected active coke is about 2.5-7.5mm, and the total circulation is 560 tons. The specific process is:

[0044] The flue gas from the tail of the power plant boiler first enters the pre-dust collector (1), and the flue gas after dust removal enters the reactor (3) through the venturi tube (2), and the active coke is added from the lower part of the desulfurization tower reactor side, and the flue gas and active The coke is fully contacted, the circulation flows, and the SO is removed 2 etc. flue gas and adsorbed SO 2 The activated coke enters the cyclone separator (4), and the flue gas is discharged; the attached SO 2 Active coke enters the active coke adding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com