Dust removal method of pulse type high-frequency power supply

A high-frequency power supply, pulsed technology, applied in the direction of external electrostatic separators, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

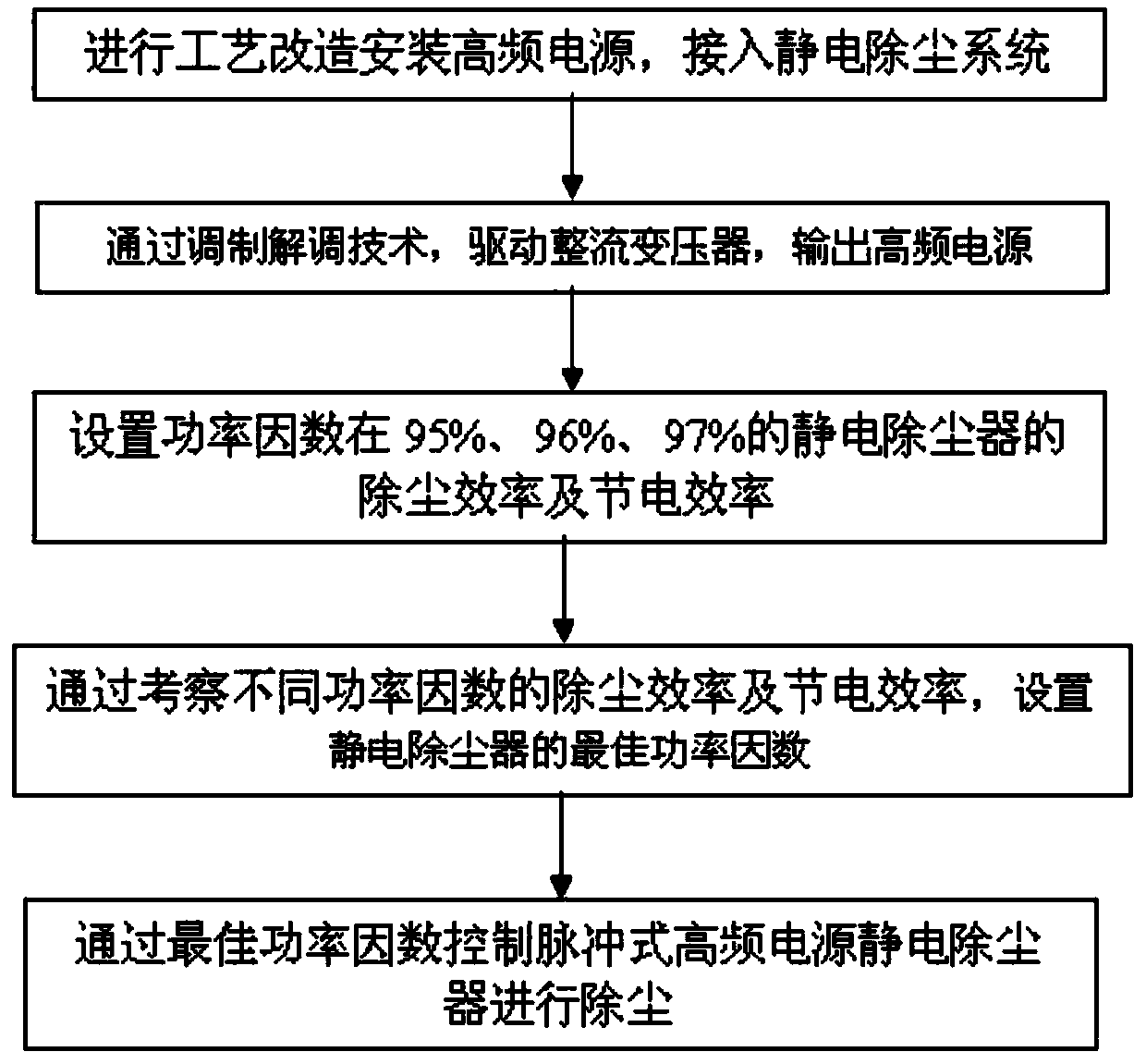

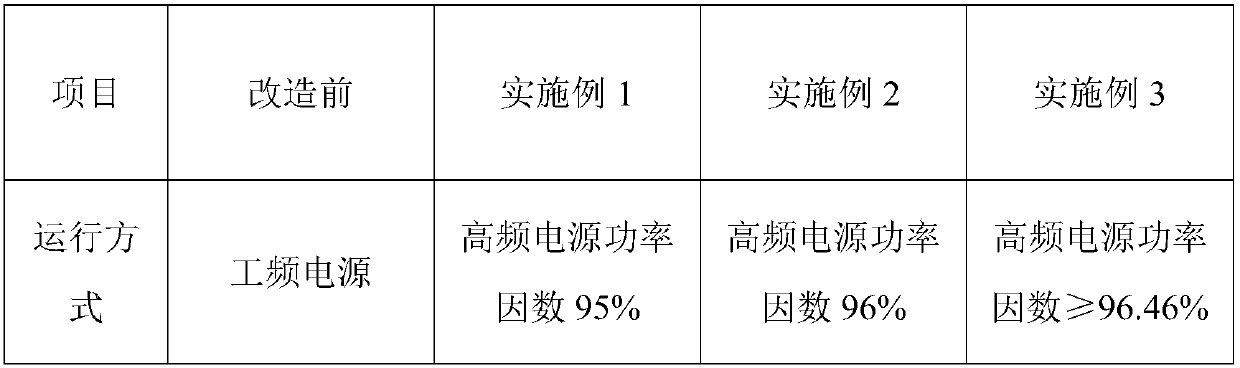

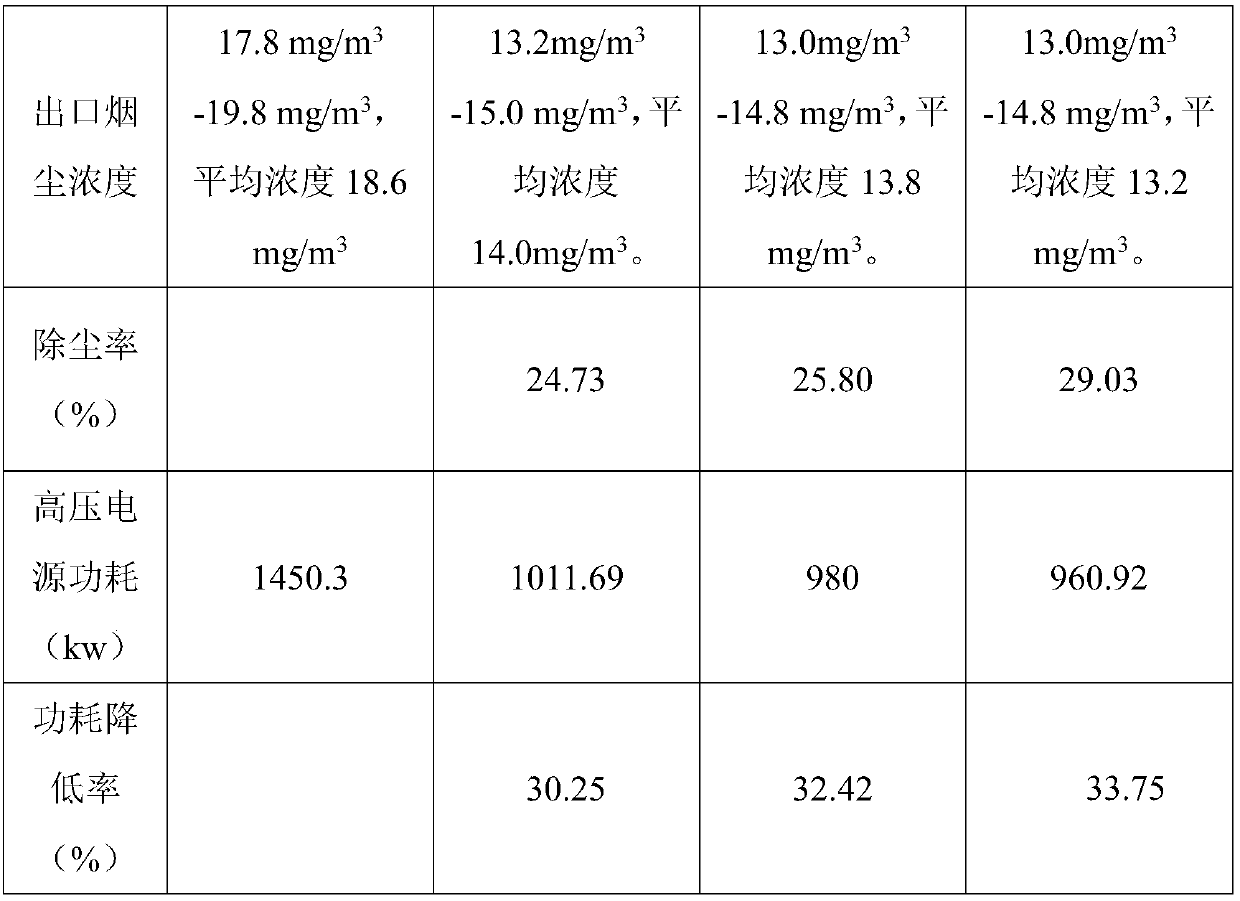

[0035] Such as figure 1 As shown in Table 1: Through technical improvement measures, process transformation, and modulation and demodulation voltage in different degrees, the dust removal efficiency of the electric field is improved. Taking the transformation of the 3# alkali furnace pulsed high-frequency power supply in the No. 2 alkali recovery plant as an example, the energy-saving and emission-reduction effects of the alkali recovery furnace with 875 tons of solids / day are studied. Adjust the output power factor of the power supply by 95% by adjusting the bus voltage and primary current control output of the pulsed high-frequency power supply. analyze. The discharge concentration of smoke and dust at the outlet of 2# electrostatic precipitator and 3# electrostatic precipitator is maintained at 13.2mg / m 3 -15.0mg / m 3 , with an average concentration of 14.0mg / m 3 . The power consumption of the electrostatic precipitator has been significantly reduced. The total high-fre...

Embodiment 2

[0037] Such as figure 1 As shown in Table 1: Through technical improvement measures, process transformation, and modulation and demodulation voltage in different degrees, the dust removal efficiency of the electric field is improved. Taking the transformation of the 3# alkali furnace pulsed high-frequency power supply in the No. 2 alkali recovery plant as an example, the energy-saving and emission-reduction effects of the alkali recovery furnace with 875 tons of solids / day are studied. By adjusting the bus voltage and primary current of the pulse type high-frequency power supply, the secondary voltage and secondary current of the output are controlled to adjust the output power factor of the power supply to 96%. analyze. The outlet smoke and dust emission concentration of 2# electrostatic precipitator and 3# electrostatic precipitator are both maintained at 13.0mg / m 3 -14.8mg / m 3 , with an average concentration of 13.8mg / m 3 . The power consumption of the electrostatic pr...

Embodiment 3

[0039] Such as figure 1 As shown in Table 1: Through technical improvement measures, process transformation, and modulation and demodulation voltage in different degrees, the dust removal efficiency of the electric field is improved. Taking the transformation of the 3# alkali furnace pulsed high-frequency power supply in the No. 2 alkali recovery plant as an example, the energy-saving and emission-reduction effects of the alkali recovery furnace with 875 tons of solids / day are studied. By adjusting the bus voltage and primary current of the pulse-type high-frequency power supply to control the output secondary voltage and secondary current, when the output power factor of the power supply is ≥96.46%, the emission concentration analysis of the dust at the outlet of the electrostatic precipitator and the power supply are carried out according to the smoke and dust turbidity meter. Power analysis. The outlet smoke and dust emission concentration of 2# electrostatic precipitator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com