Process of using air-cooled island exhaust steam waste heat for zero-discharge treatment of thermal power plant wastewater

A technology for thermal power plants and air cooling islands is applied in the field of zero-discharge treatment of waste water in thermal power plants, which can solve the problems of high cost, high energy consumption and low operating cost, and achieve the effects of increasing utilization, reducing heat pollution, and reducing coal consumption for power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

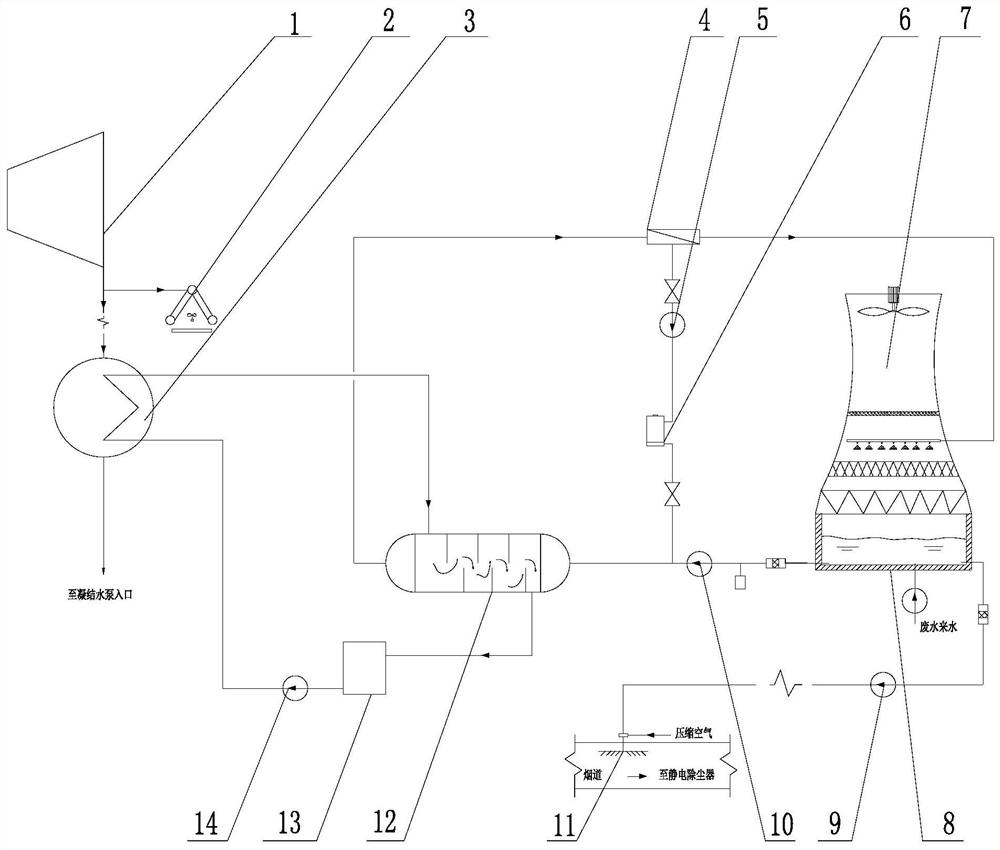

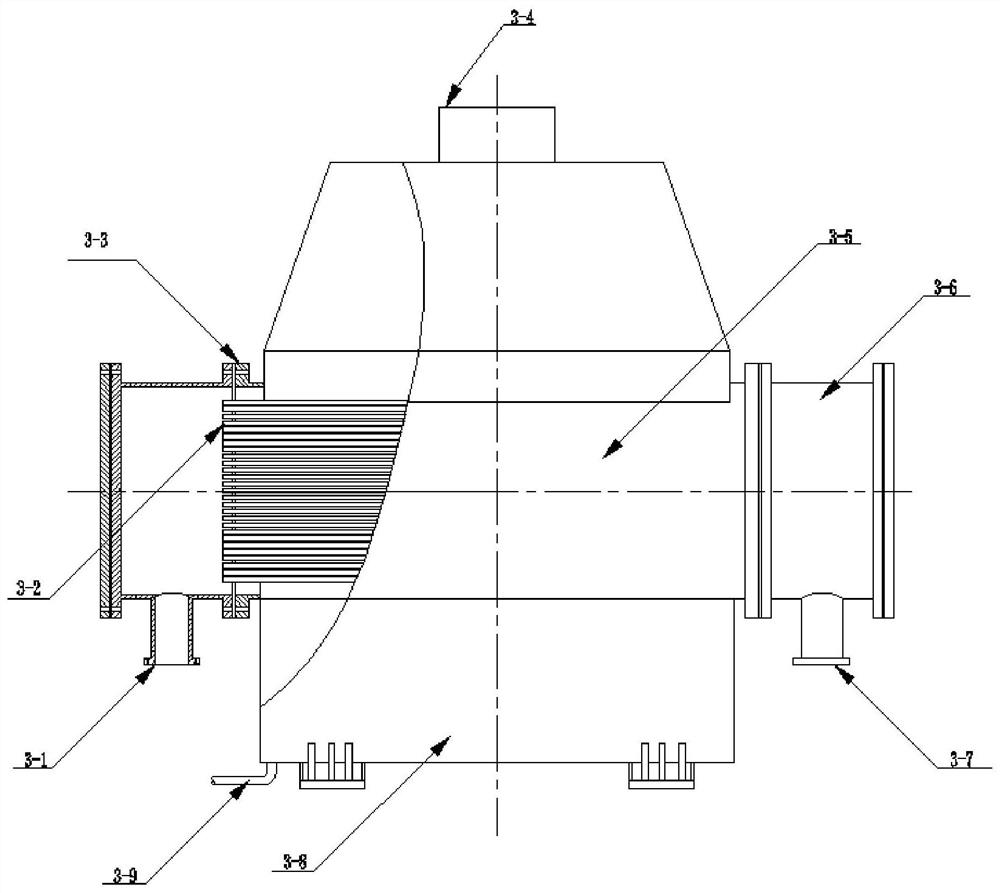

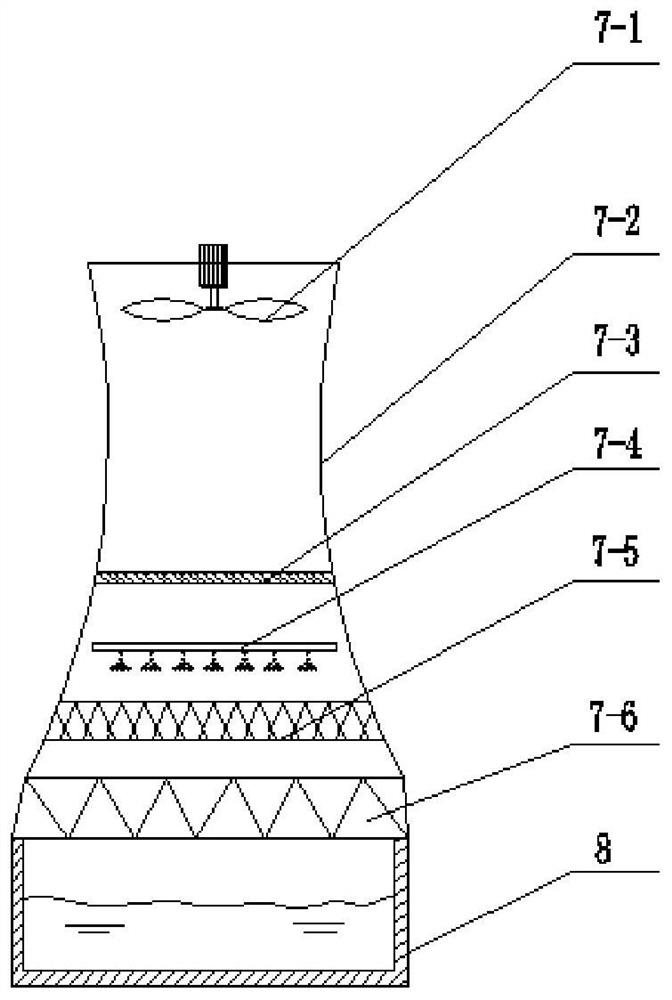

[0026] exist figure 1 , 2 , 3, 4, and 5, the present invention uses the air-cooled island exhaust steam waste heat for the process of thermal power plant waste water zero discharge treatment, the low-pressure cylinder exhaust main pipe of the steam turbine 1 and the shell-side steam inlet pipe of the exhaust steam condenser 3 connected to each other, and a part of the exhaust steam split into the air-cooled island 2 is introduced into the shell-side steam inlet pipe of the exhaust-steam condenser 3, and the condensate water outlet pipe on the shell-side of the exhaust-steam condenser 3 is connected with the inlet of the condensate pump, and the exhaust steam condensate The circulating cooling water on the tube side of the tube 3 is demineralized water or demineralized water. After the circulating cooling water is heated by the exhaust steam condenser 3, the hot water from the outlet pipe on the tube side of the exhaust steam condenser 3 enters the water-water heat exchanger 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com