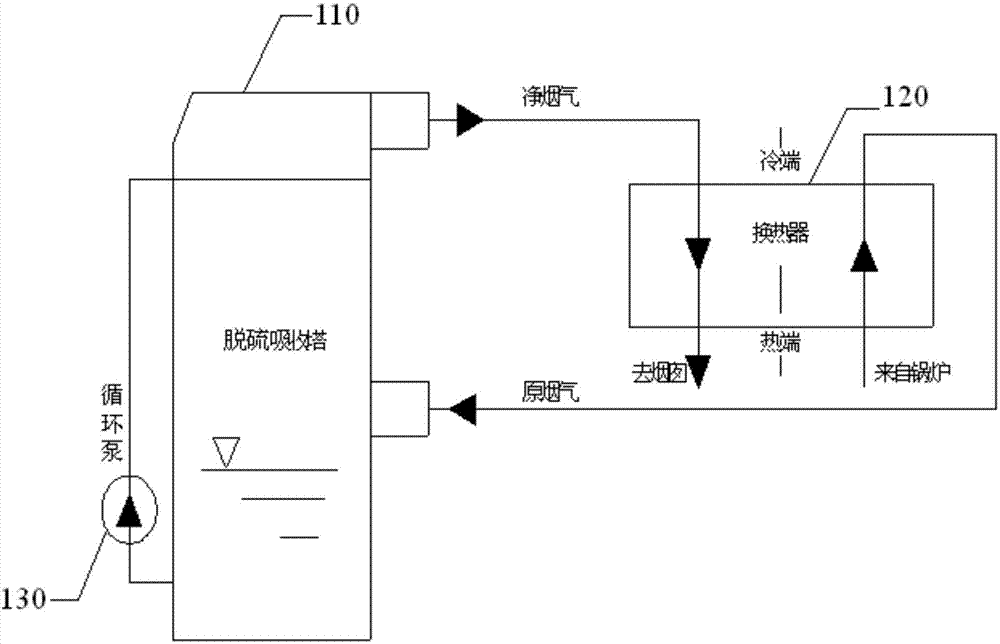

Sampling method and system for blockages in desulfurization system heat exchanger

A desulfurization system and blockage technology, applied in sampling devices and other directions, can solve the problems of not being able to fully grasp the blockage, the distribution of the blockage components, and the inability to effectively relieve the blockage of the heat exchanger, so as to improve the efficiency and alleviate the blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

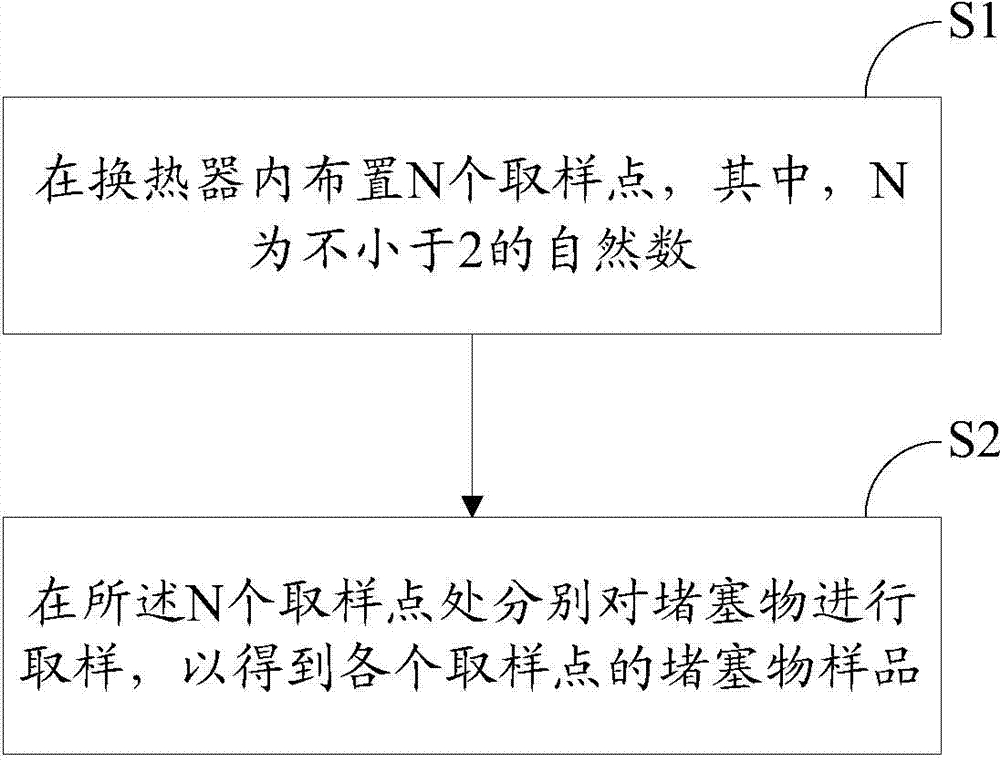

[0042] Embodiment 1 of the present invention discloses a method for sampling blockages in heat exchangers of desulfurization systems, such as figure 2 As shown, the method includes:

[0043] S1: Arrange N sampling points in the heat exchanger, where N is a natural number not less than 2.

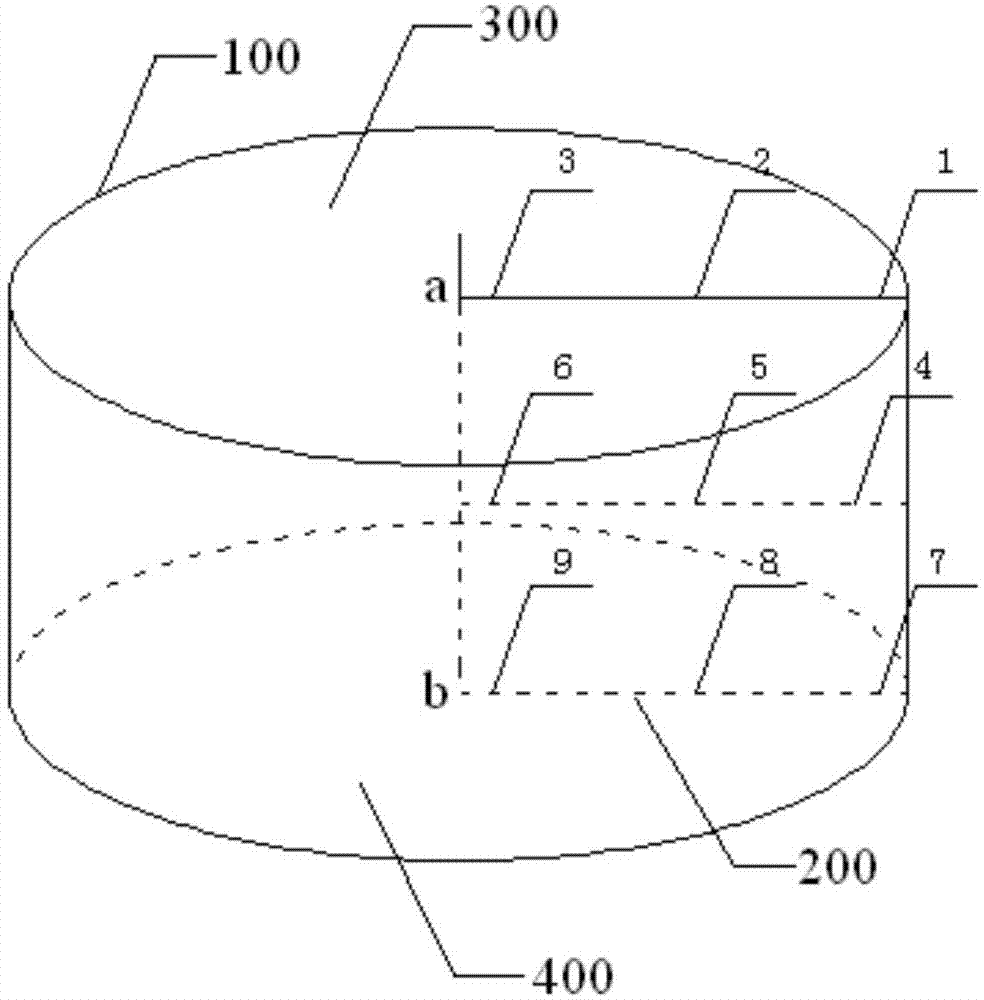

[0044] The arranging N sampling points in the heat exchanger includes: evenly arranging 9 sampling points on the heat exchange fins of the heat exchanger. Specifically, 3 sampling points are evenly arranged at the edge of the heat exchange fins, 3 sampling points are evenly arranged at the middle of the heat exchange fins, and 3 sampling points are evenly arranged at the center of the heat exchange fins.

[0045] See image 3 , 200 is the heat exchange fin of the cylindrical heat exchanger 100, and the axis ab is the central axis of the heat exchanger 100. Since the heat exchanger is a uniform and slow rotating device, its blockage is in the same cross-section of the cylindrical heat exch...

Embodiment 2

[0052] Embodiment 2 of the present invention, on the basis of Embodiment 1, discloses another process flow of the sampling method for heat exchanger blockages in the desulfurization system. On the basis of sampling, it also includes the follow-up steps of analyzing and processing the blockage samples obtained by sampling, such as Figure 4 As shown, in addition to steps S1 and S2, the sampling method of the blockage in the heat exchanger of the desulfurization system in this embodiment also includes:

[0053] S3: Analyze the blockage samples at each sampling point to obtain the composition and quantity distribution of the blockage, and take corresponding blockage control measures according to the composition and quantity distribution of the blockage.

[0054] Wherein, step S3 specifically includes:

[0055] When the composition and quantity of blockages at each sampling point are basically similar to the composition of ash in the flue gas, the efficiency of electrostatic prec...

Embodiment 3

[0059] Embodiment 3 of the present invention discloses a sampling system for blockages in heat exchangers of desulfurization systems, which corresponds to the sampling method for blockages in heat exchangers of desulfurization systems disclosed in Embodiment 1 or Embodiment 2. Please refer to Figure 5 , the sampling system for heat exchanger blockage in the desulfurization system includes a sampling point arrangement module 510 and a sampling module 520, wherein the sampling point arrangement module 510 is used to arrange N sampling points in the heat exchanger, and N is not less than 2 A natural number; the sampling module 520 is configured to respectively sample the blockage at the N sampling points, so as to obtain blockage samples at each sampling point.

[0060] Corresponding to the sampling method for the blockage in the heat exchanger of the desulfurization system disclosed in Example 2, this embodiment also provides another structure of the sampling system for the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com