Multistage anaerobic digestion strengthened gas production method

An anaerobic digestion and anaerobic reaction device technology, which is applied in the process field of multi-stage anaerobic digestion to enhance gas production, can solve the problem of low degradation rate of organic matter in sludge anaerobic digestion, achieve enhanced sludge stabilization effect, and improve The effect of stable sludge quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

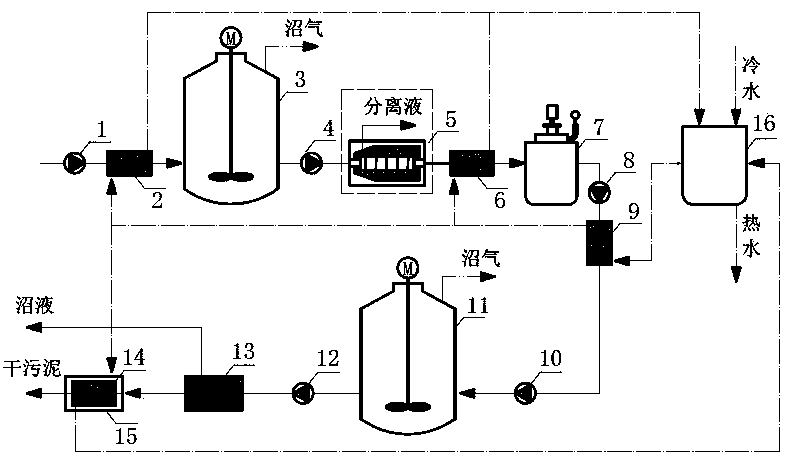

Method used

Image

Examples

Embodiment 1

[0023] (1) Dewatered sludge obtained from Shanghai Anting Wastewater Treatment Plant (solid content 20%, VS / TS 51%, pH 7.6, ammonia nitrogen concentration (TAN) 739 mg L -1 ,) and stored at 4°C. 2 hours before feeding, take 400g of dewatered sludge and store it in an incubator at 37°C;

[0024] (2) When feeding, add 400g of dewatered sludge (the solid content of the feed sludge is 20%) into the 1# anaerobic fermentation device with an effective volume of 6L, and the feed amount is 1 / 15 of the inoculated sludge ; The original 6L material in the fermentation device is anaerobic fermentation sludge, the temperature of the material in the fermentation device is controlled at 35±1°C, the residence time of the material in the fermentation device is 15 days, the material is continuously fed in and out every day, and the stirring device is controlled Start every 20 minutes for 10 minutes and stop for 10 minutes;

[0025] (3) After the anaerobic fermentation is stabilized, the organi...

Embodiment 2

[0031] (1) Dewatered sludge obtained from Shanghai Anting Wastewater Treatment Plant (solid content 20%, VS / TS 51%, pH 7.6, ammonia nitrogen concentration (TAN) 739 mg L -1 ,) and stored at 4°C. 2 hours before feeding, take 375g of dewatered sludge and 125g of deionized water and store them in an incubator at 37°C;

[0032] (2) When feeding, add 375g of dewatered sludge and 125g of deionized water (the solid content of the feed sludge is 15%) into the 1# anaerobic fermentation device with an effective volume of 6L, and the amount of feed is inoculation 1 / 12 of the sludge; the original 6L material in the fermentation device is anaerobic fermentation sludge, the temperature of the material in the fermentation device is controlled at 35±1°C, the residence time of the material in the fermentation device is 12 days, and it is continuously in and out every day material, and control the stirring device to start every 20 minutes for 10 minutes and stop for 10 minutes;

[0033] (3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com