UBF anaerobic reactor based on biochar carrier

An anaerobic reactor and biochar technology, which is applied in the treatment of granular microbial carriers, anaerobic digestion treatment, biological water/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

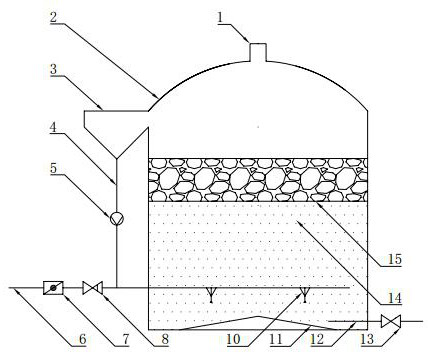

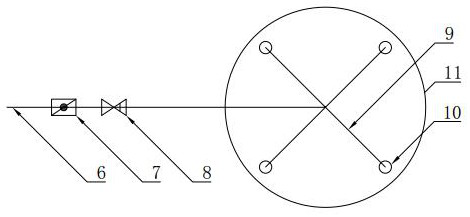

[0016] Embodiment: a kind of UBF anaerobic reactor based on biochar, such as figure 1 , figure 2 As shown, the reaction tank 2 is included, and the upper part of the reaction tank 2 is provided with a biological filler layer 15, and the biological filler layer 15 has biochar. After the effluent passes through the filter layer, the loose sludge that is not attached to the biochar carrier is retained, The microorganisms are adsorbed on the surface of the biochar filter layer by attaching and forming a film, forming a biofilm on the upper part of the reaction tank, reducing the loss of sludge, ensuring sufficient microbial biomass in the reactor, and improving the load shock resistance of the reactor , the bottom of the reaction tank 2 is a granular sludge layer 14, the granular sludge layer 14 contains biochar as a carrier for microbial agglomeration, the large porosity and rich polar functional groups on the surface of the biochar improve the activity of microorganisms and reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com