Sludge pretreatment method and method of producing acid by anaerobic fermentation of sludge

A pretreatment, sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem that the sludge has not been properly treated and disposed, and the ultrasonic pretreatment of sludge has high energy consumption , the proportion of less than 20%, etc., to achieve the effect of significant cavitation effect, long fermentation time, and increased volatile acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

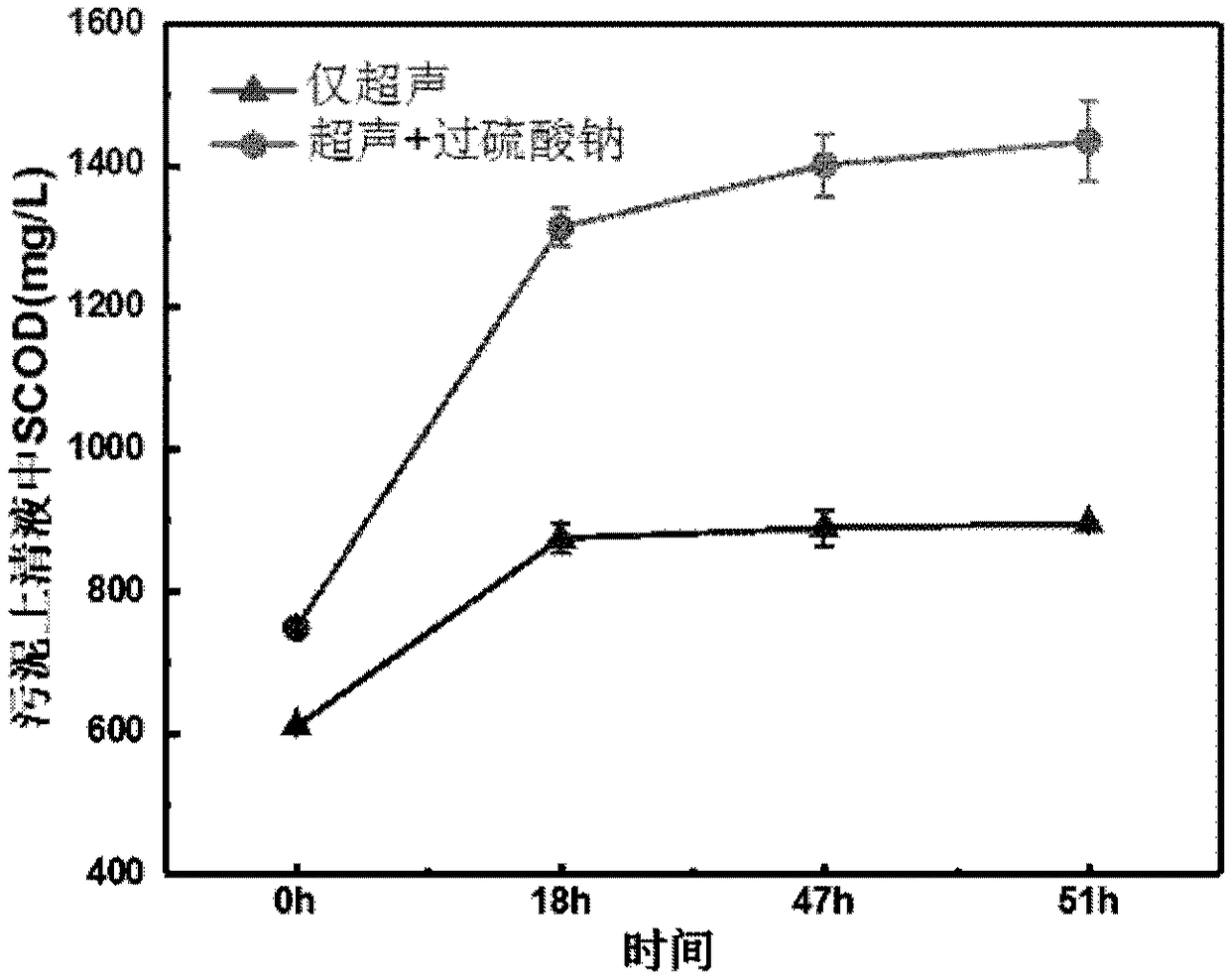

[0042] A method for producing acid by anaerobic fermentation of sludge pretreated by ultrasonic coupling with persulfate, specifically carried out according to the following steps:

[0043] Step 1. At room temperature (25°C), sodium persulfate was used as the oxidant required for advanced oxidation technology during the experiment, and 0.24g of sodium persulfate was weighed with 100ml of return sludge from urban sewage treatment plants (sludge concentration 14g / L) Fully mix in a 100ml beaker to obtain mixed sludge, that is, control the concentration of sodium persulfate to 10mM / L.

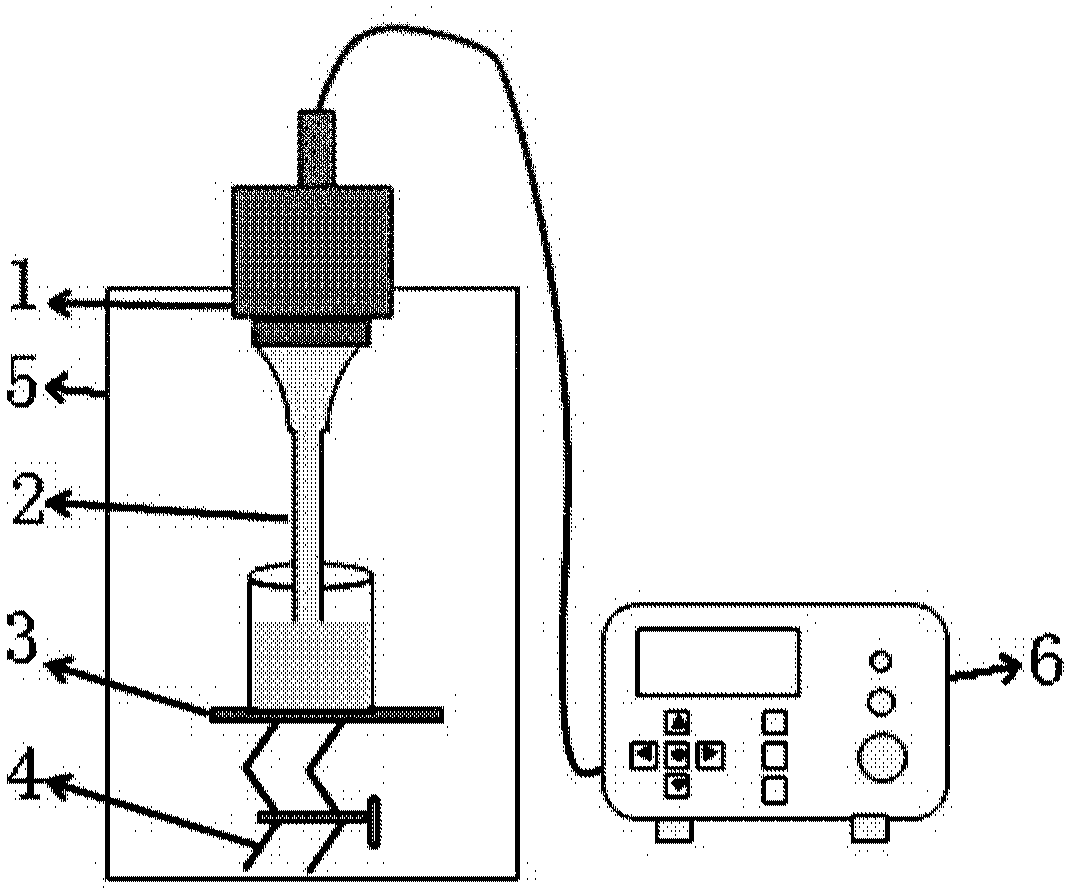

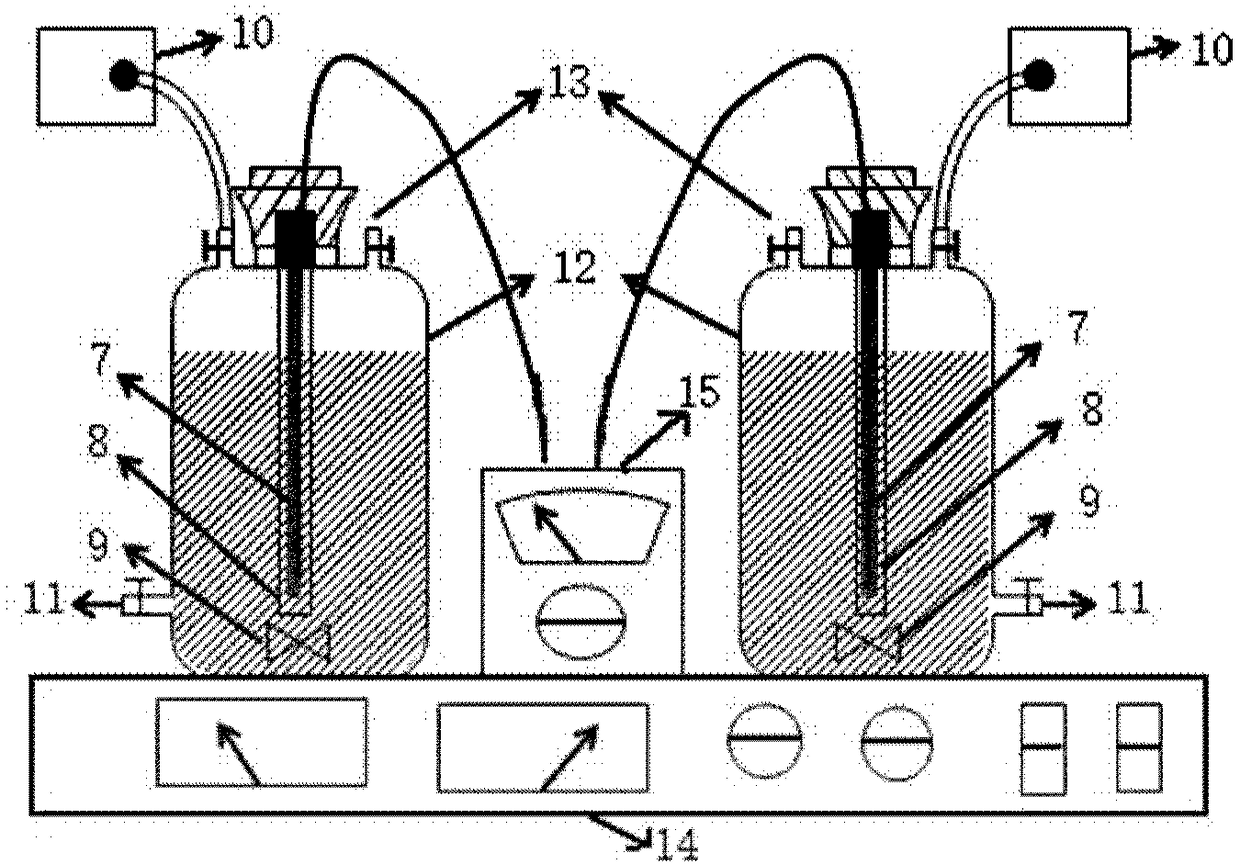

[0044] Step 2, use such as figure 1 The ultrasonic cell breaker shown in the figure performs ultrasonic treatment on the mixed sludge in step one. The ultrasonic breaker is the JY90-II type ultrasonic cell breaker of Xinzhi Company, including: a controller 6, a soundproof box 5, and a height adjustment device 4 set in the soundproof box 5, a sample table 3, a horn 2 and a changer. The transducer ...

Embodiment 2 to 5

[0054] Similar to the method of Example 1, according to the reagents, dosage and conditions shown in Table 1, the sludge is subjected to the pretreatment of step 1 to step 3, and after pretreatment, sampling is carried out for COD measurement. It can be seen that the pretreatment method of the present invention can effectively Increasing the SCOD content is beneficial to the subsequent anaerobic fermentation treatment.

[0055]

[0056] To sum up, the present invention uses advanced oxidation technology combined with ultrasonic to strengthen sludge floc cracking, which greatly improves the degree of sludge cracking, improves the biochemical properties of sludge, and provides more abundant sludge for the subsequent anaerobic fermentation hydrolysis stage. Substrate, thus greatly improving the volatile acid production in the subsequent anaerobic fermentation process of sludge, effectively alleviating the limitation caused by the hydrolysis stage in the sludge anaerobic digesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com