Pipeline type sludge slag removal automation control system and control method

An automatic control and pipeline-type technology, applied in chemical instruments and methods, sludge treatment, separation methods, etc., can solve the problems of high cost of sludge treatment, low degree of automation, large slag particle radius, etc., and achieve the treatment effect Ideal, the effect of improving mixing efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

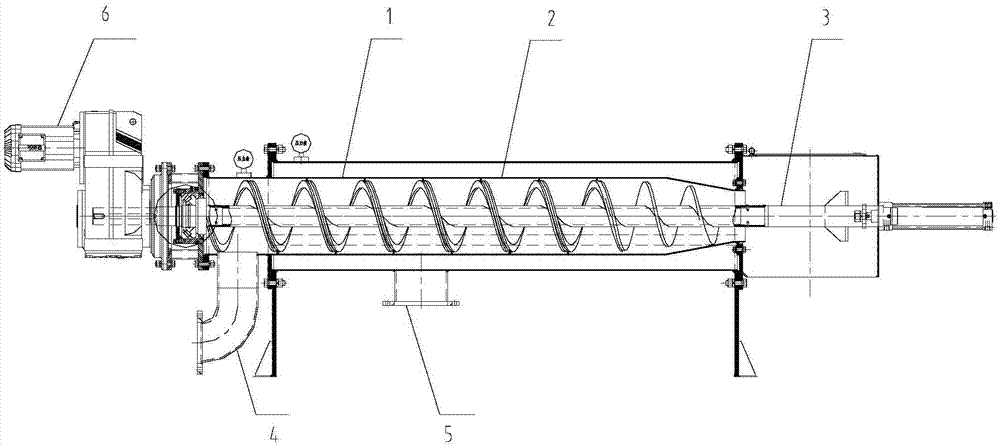

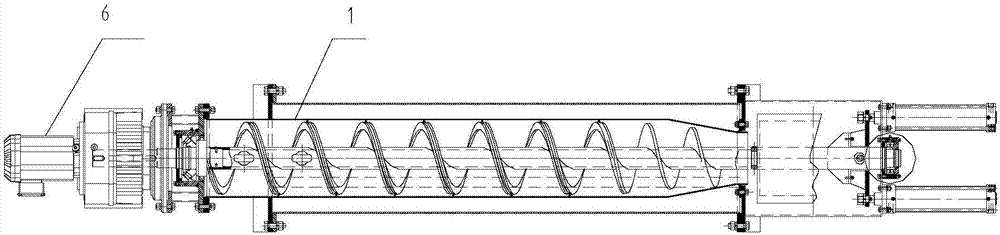

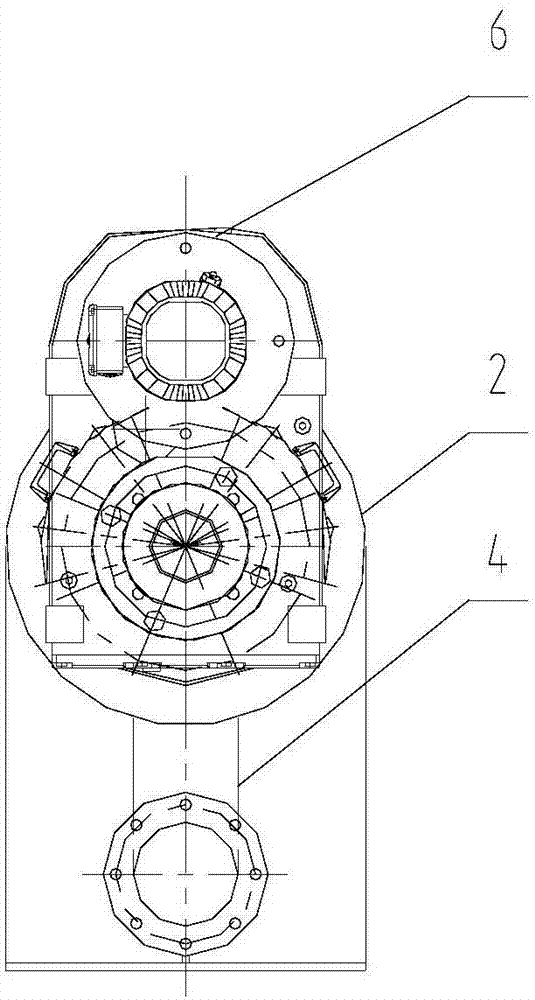

[0036] Attached below Figure 1-10 The pipeline type sludge removal automatic control system and its control method of the present invention are described in detail.

[0037] A pipeline-type sludge removal automation control system, characterized in that the automation control system includes a pipeline-type sludge removal machine 1 and a waterproof electric control box, wherein the pipeline-type sludge removal machine includes a horizontal horizontal The multifunctional filter cartridge 2 and the dewatering press device 3 arranged in the multifunctional filter cartridge are provided with a sludge inlet port 4 and a sludge outlet port 5 on the multifunctional filter cartridge; the cylinder of the multifunctional filter cartridge The inner cavity of the body is horizontally equipped with a spiral conveying assembly, which is electrically connected to the driving device 6; the spiral conveying assembly is respectively connected to the sludge inlet and the sludge outlet; the spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com