Biomass waste treatment system and method

A technology of biomass waste and treatment system, applied in the direction of solid waste removal, chemical instruments and methods, transportation and packaging, etc. Low oxygen digestion performance and other problems, to achieve excellent separation effect, improve dehydration and anaerobic digestion performance, improve the effect of harmlessness and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

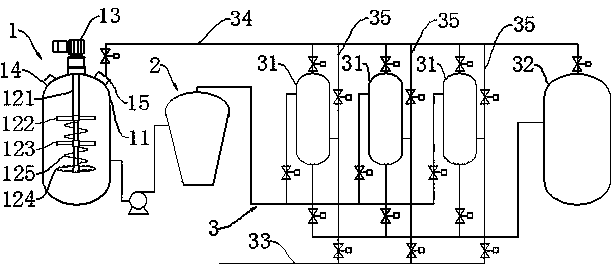

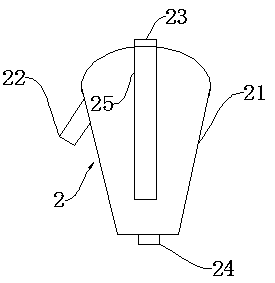

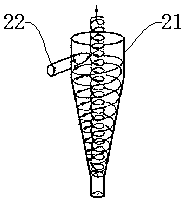

[0033] Such as figure 1 As shown, this embodiment provides a biomass waste treatment system, which includes a process control unit, and a demulsification tank 1 , a cyclone separator 2 and a hydrothermal reaction unit 3 connected in sequence. The demulsification tank 1, the cyclone separator 2 and the hydrothermal reaction unit 3 are respectively connected to the process control unit so that the process control unit can control its working process.

[0034] In this embodiment, the process control unit is a programmable logic controller (PLC), which is an existing technology understandable by those skilled in the art, and will not be described in detail herein.

[0035] The demulsification tank 1 includes a tank body 11, an agitator is arranged inside the tank body 11, and the agitator rotates under the drive of a motor 13, and the motor 13 is arranged on the top outside of the tank body 11. The stirrer 13 includes a stirring shaft 121, one end of the stirring shaft 121 is con...

Embodiment 2

[0045] This embodiment provides a treatment method for biomass waste, which is based on the biomass waste treatment system in Example 1, which includes the following steps:

[0046] Step 1: Under the automatic control of the process control unit, transport the material to the demulsification tank, use the flash steam generated by the flash treatment to preheat, raise the temperature to 60-100°C, and demulsify under the action of the demulsifier , and at the same time break some living cells and flocs, promote the dissolution of bound water, reduce the viscosity of the material and then enter the cyclone separator.

[0047] Step 2: The liquid phase material enters along the tangential direction of the inner wall of the cyclone separator. Due to its special structure, the liquid phase material enters the cyclone separator, and the material uses the involute principle to form first downwards and then upwards in the cyclone separator. The two-stage cyclone, under the action of cen...

Embodiment 3

[0052] This embodiment provides a demulsifier, which can be applied to the understanding process in Example 2, especially for the understanding of biomass waste, for promoting solid-liquid separation in biomass waste and reducing its viscosity.

[0053] The demulsifier provided in this embodiment consists of 90-120 parts by mass of propylene oxide, 30-40 parts of triethanolamine, 25-40 parts of sodium dodecylsulfonate, and 20-28 parts of C2-C6 carboxylic acid , 18-25 parts of ethylene glycol monobutyl ether, and 12-15 parts of ammonium chloride.

[0054] Take 100 parts of propylene oxide, 40 parts of triethanolamine, 30 parts of sodium dodecylsulfonate, 25 parts of n-hexanoic acid, 20 parts of ethylene glycol monobutyl ether, and 12 parts of ammonium chloride, and mix them uniformly to obtain a demulsifier.

[0055] Take a biomass waste, viscous sludge, 19 ℃, divide it into four parts on average, put them into transparent glass cups; The condition of 6g / 100g sludge is added w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com