Sludge MFC-anaerobic digestion coupling system and performance enhancing method thereof

An anaerobic digestion and coupling system technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of failure to achieve secondary use of energy, no comprehensive consideration relationship, high cost of activated carbon, etc. Achieve the effect of directional control and recycling, reduce energy consumption of resources, and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below through specific examples.

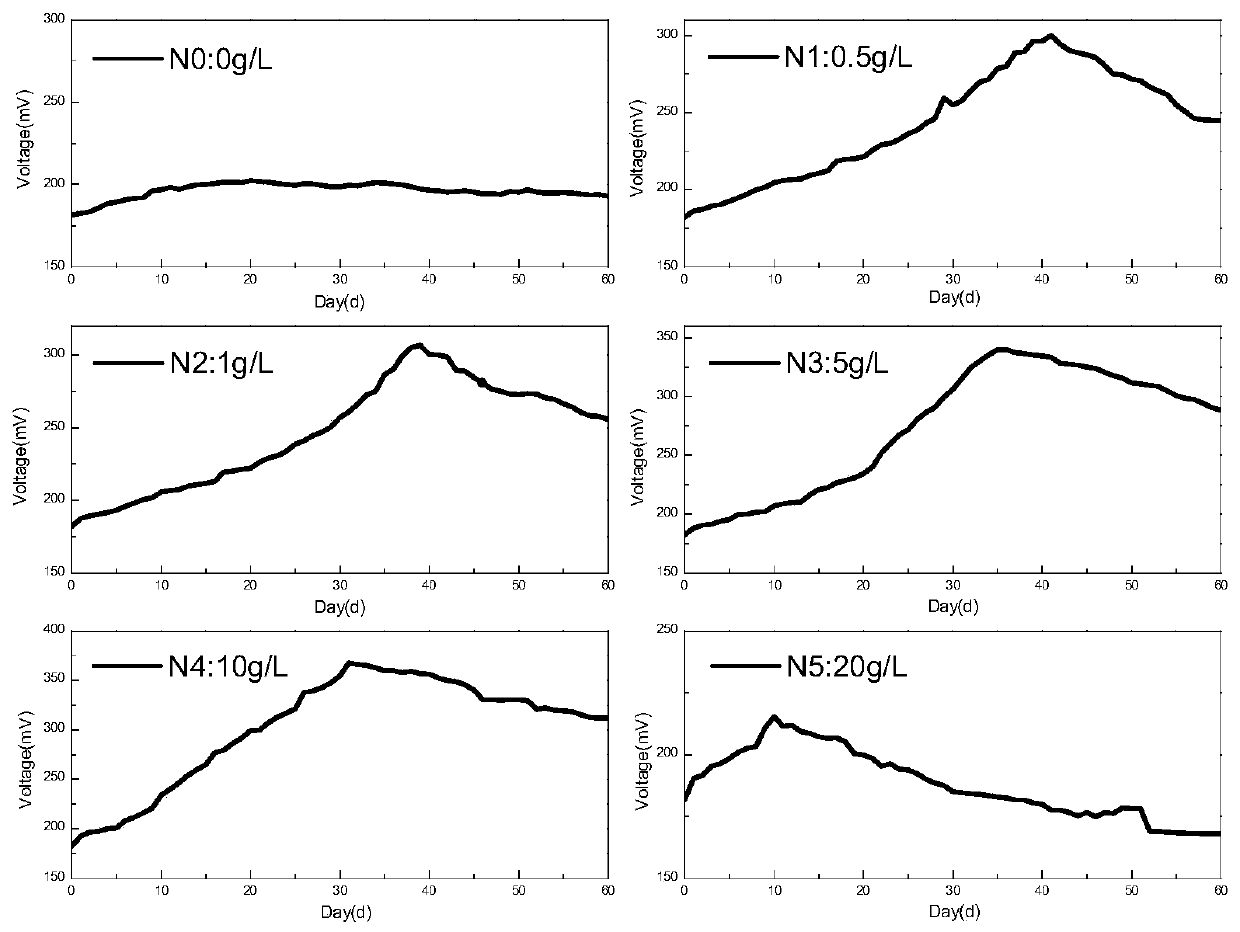

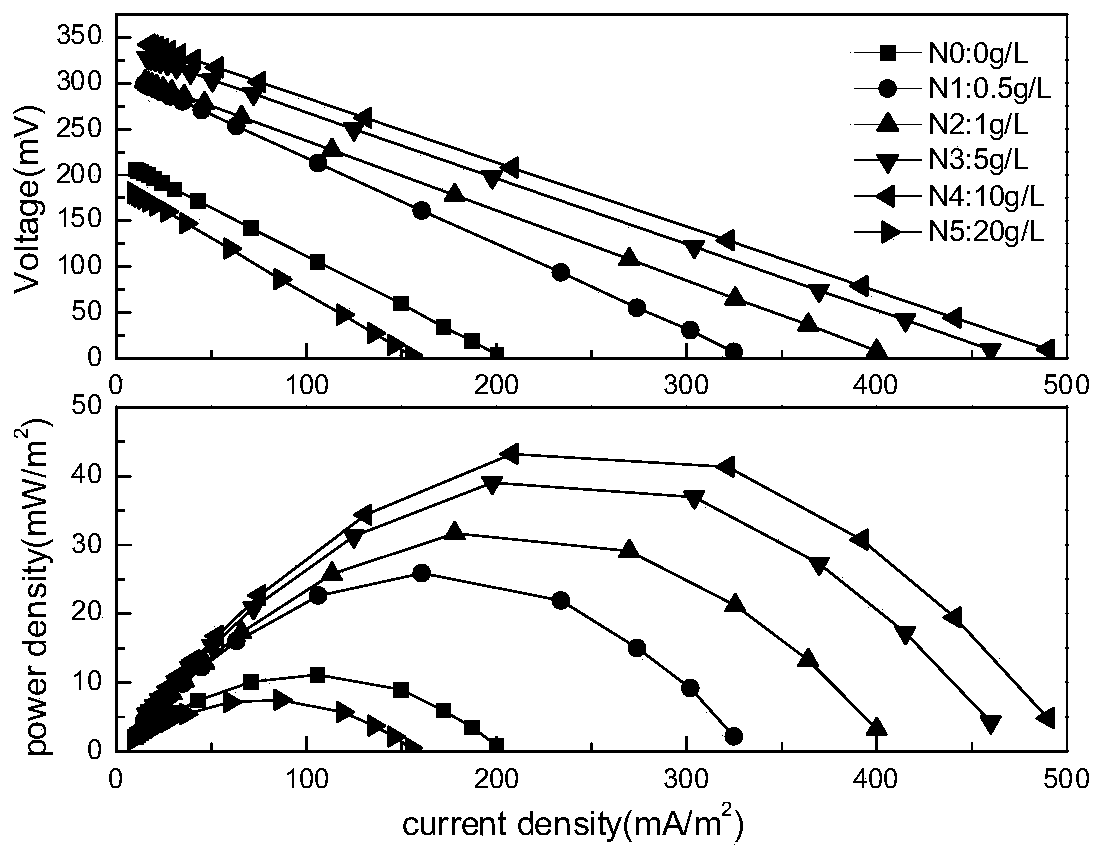

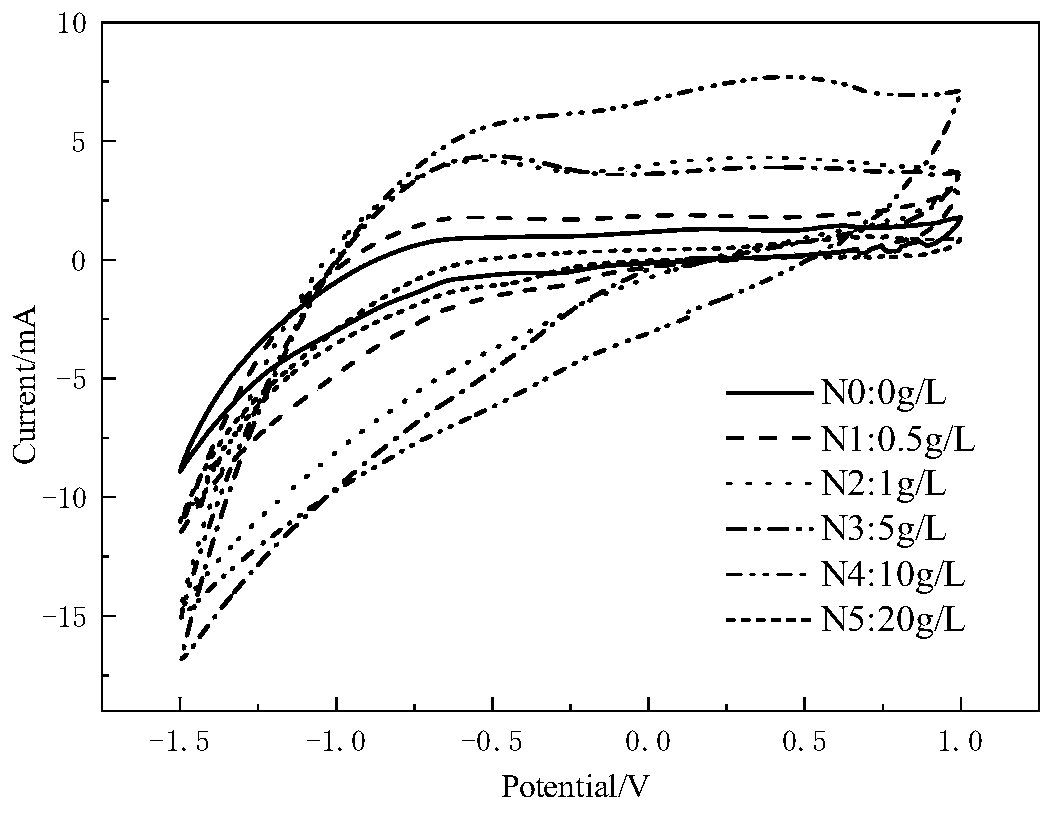

[0031] This embodiment provides a sludge MFC-anaerobic digestion coupling system and a method for enhancing performance by using scrap iron chips. First, build a set of "sludge MFC-anaerobic digestion coupling system", and add a series of waste iron scraps with different concentrations (N0-N5) to the sludge MFC-anaerobic digestion coupling system, where N0 means no input Add iron scraps, as a control group, N1~N5 are: 0.5g / L, 1g / L, 5g / L, 10g / L, 20g / L, and then domesticate anode sludge with iron-containing sludge as anode substrate electrogenic bacteria and anaerobic digesters. The reactor of the sludge MFC-anaerobic digestion coupling system adopts the MFC double-chamber configuration (12cm×12cm×18cm), including a closed anaerobic anode chamber and an aerated cathode chamber. The anode chamber and the cathode chamber are connected by a communication pipe. A proton exchange membrane (m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com