Method for strengthening alkaline fermentation sludge reduction of excess sludge by adding NaCl

A technology for excess sludge and sludge reduction, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of limited reduction of fermentation sludge and limited treatment and disposal of excess sludge, so as to accelerate autolysis. Speed, enhanced sludge reduction effect, increased release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

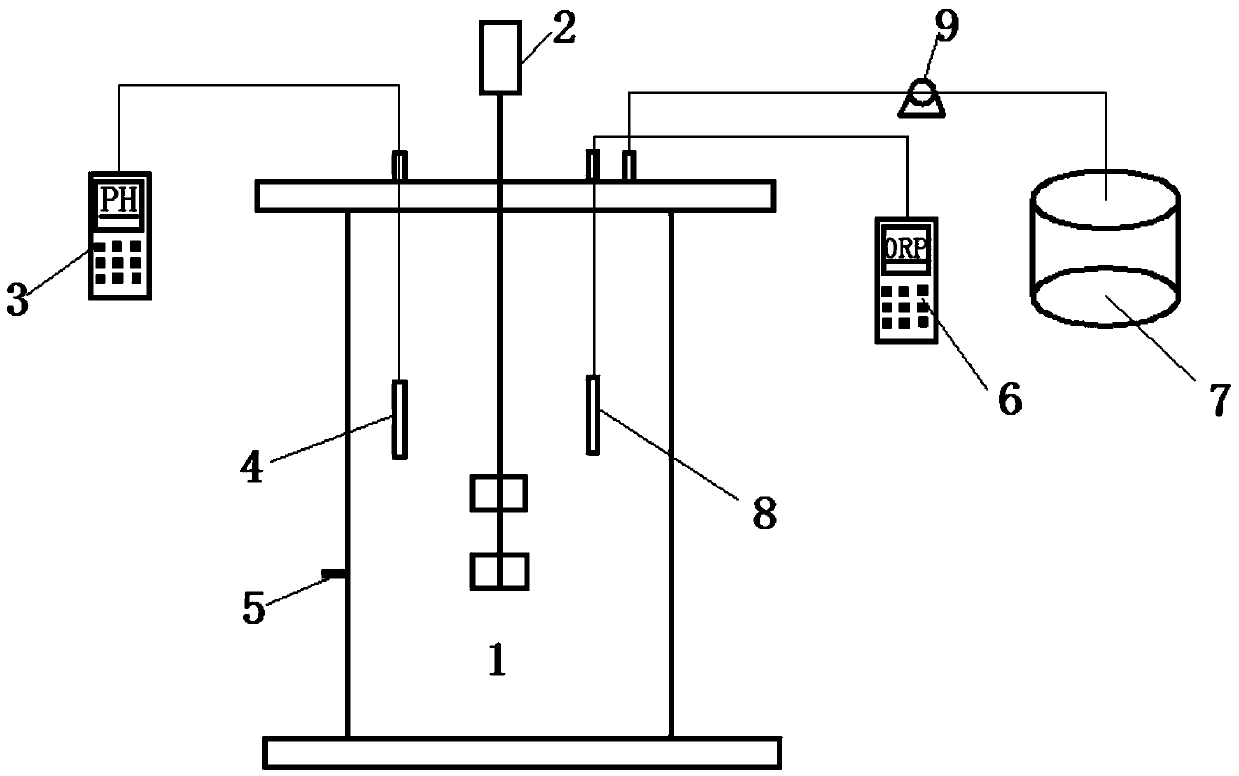

[0022] Add 1.2L of eluted sludge into the small SBR1 reactor without adding sodium chloride, turn on the agitator 2 and stir for 60 minutes, then pump it into the sodium hydroxide regulator to adjust the pH to 10±0.1, and start from the The sampling port 5 samples and measures the MLSS and MLVSS of the remaining sludge.

example 2

[0024] Add 1.2L of elutriated sludge into the small SBR1 reactor, add sodium chloride at one time, so that the concentration of sodium chloride is 2.0g / L; turn on the stirrer 2 to stir, and pump in hydrogen after stirring for 60min Sodium oxide adjusts the pH in the device to 10±0.1, and samples are taken from the sampling port 5 every other day to measure the MLSS and MLVSS of the remaining sludge.

example 3

[0026] Add 1.2L of elutriated sludge into the small SBR1 reactor, add sodium chloride at one time, so that the concentration of sodium chloride is 9.0g / L; turn on the stirrer 2 to stir, and pump in hydrogen after stirring for 60min Sodium oxide adjusts the pH in the device to 10±0.1, and samples are taken from the sampling port 5 every other day to measure the MLSS and MLVSS of the remaining sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com