Residual sludge reduction system and method for wastewater biochemical treatment system

A biochemical treatment and sludge reduction technology, which is applied in water/sewage treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of increased water salinity, increased difficulty of sludge digestion, and high operating costs, achieving Promote sludge reduction, effect improvement, and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

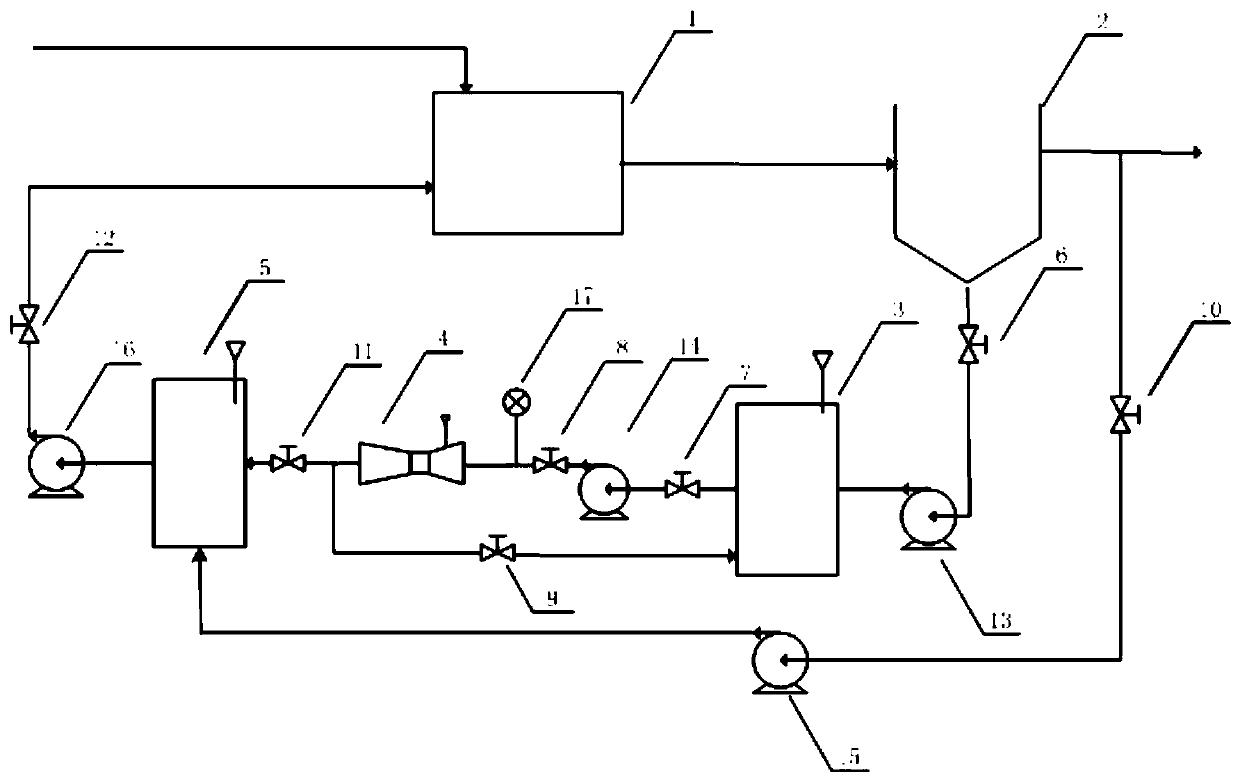

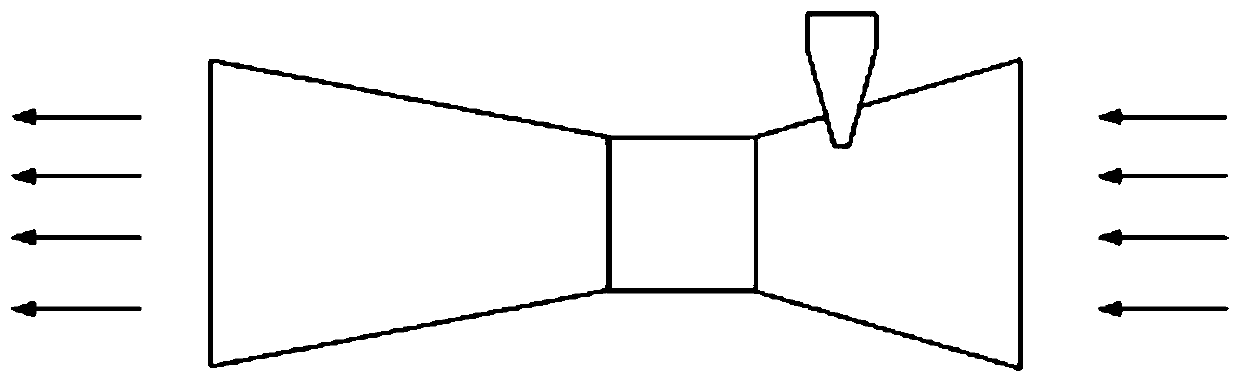

[0027] A wastewater biochemical treatment system excess sludge reduction system, including a secondary settling tank 2 connected to the sludge outlet of a biochemical treatment unit 1, a pretreatment tank 3 connected to the secondary settling tank 2 in sequence, a hydraulic cavitation device 4, and a pH adjustment pool 5, the outlet of the pH adjustment pool 5 is connected to the biochemical treatment unit 1 to form a loop, and the outlet of the hydraulic cavitation device 4 leads another branch path back to the pretreatment pool 3, and the pretreatment pool 3 is provided with additional pretreatment Reagent inlet.

[0028] The specific method is as follows:

[0029] The waste water is treated intermittently. After being treated by the biochemical treatment unit 1, it enters the secondary settling tank 2. The waste water settled in the secondary settling tank 2 is discharged, and the valve 6 is opened to transport the remaining sludge in the secondary settling tank 2 to the pr...

Embodiment 2

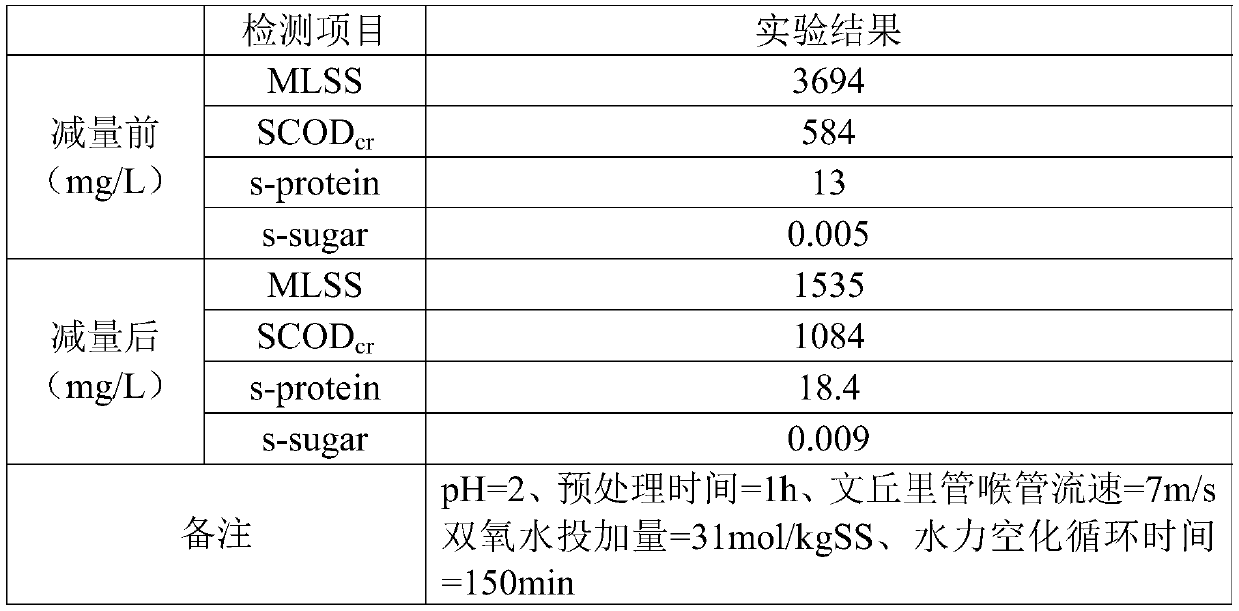

[0034] As in the operation steps of Example 1, run the system according to the conditions in Table 2, take the sludge in the secondary settling tank and measure the MLSS, SCODcr, s-protein (soluble protein), s-sugar (soluble sugar) before the reduction , after the hydraulic cavitation device, the above-mentioned data of the sludge sample after the reduction were measured, and the results are shown in Table 2:

[0035] Table 2

[0036]

Embodiment 3

[0038] As in the operation steps of Example 1, run the system according to the conditions in Table 3, take the sludge in the secondary settling tank and measure the MLSS, SCODcr, s-protein (soluble protein), s-sugar (soluble sugar) before the reduction , after the hydraulic cavitation device, the above-mentioned data of the sludge sample after the reduction were measured, and the results are shown in Table 3:

[0039] table 3

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com