Cleaning type integrated effluent disposal system and operation method

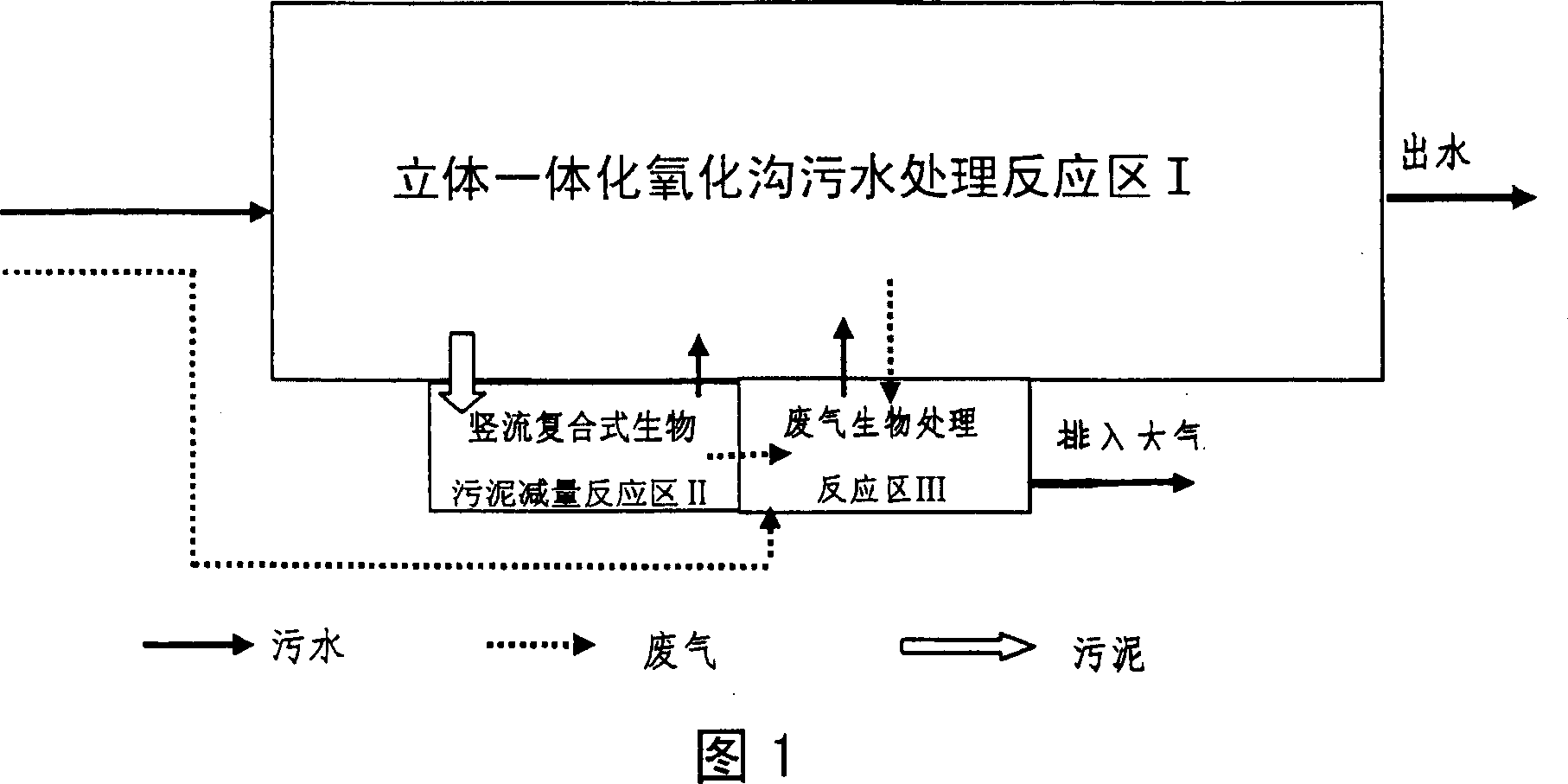

A sewage treatment system and sewage treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Pollutants, poor system operation and adjustment performance, etc., to improve the effect of sludge reduction, eliminate adverse effects, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

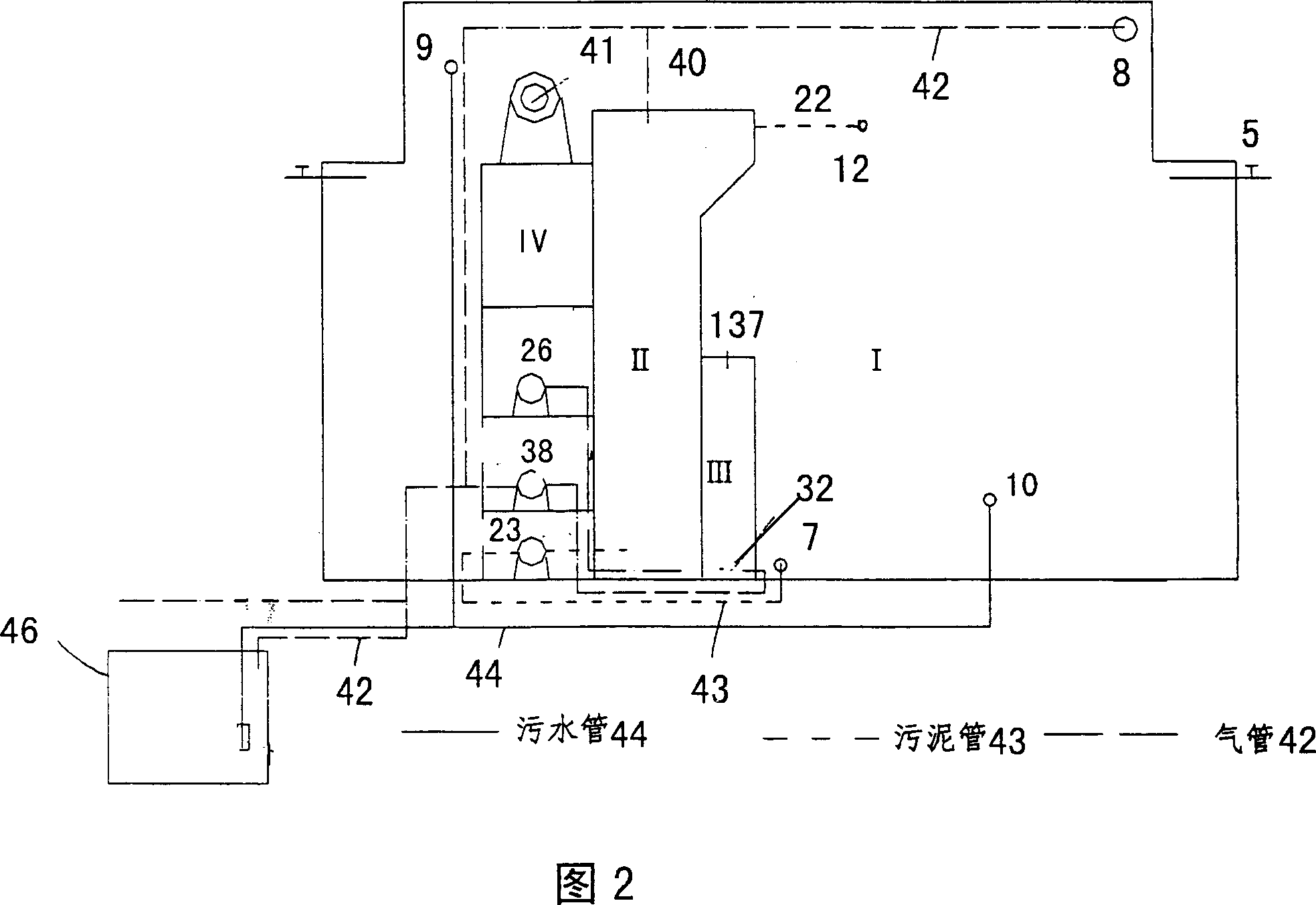

Method used

Image

Examples

Embodiment 1

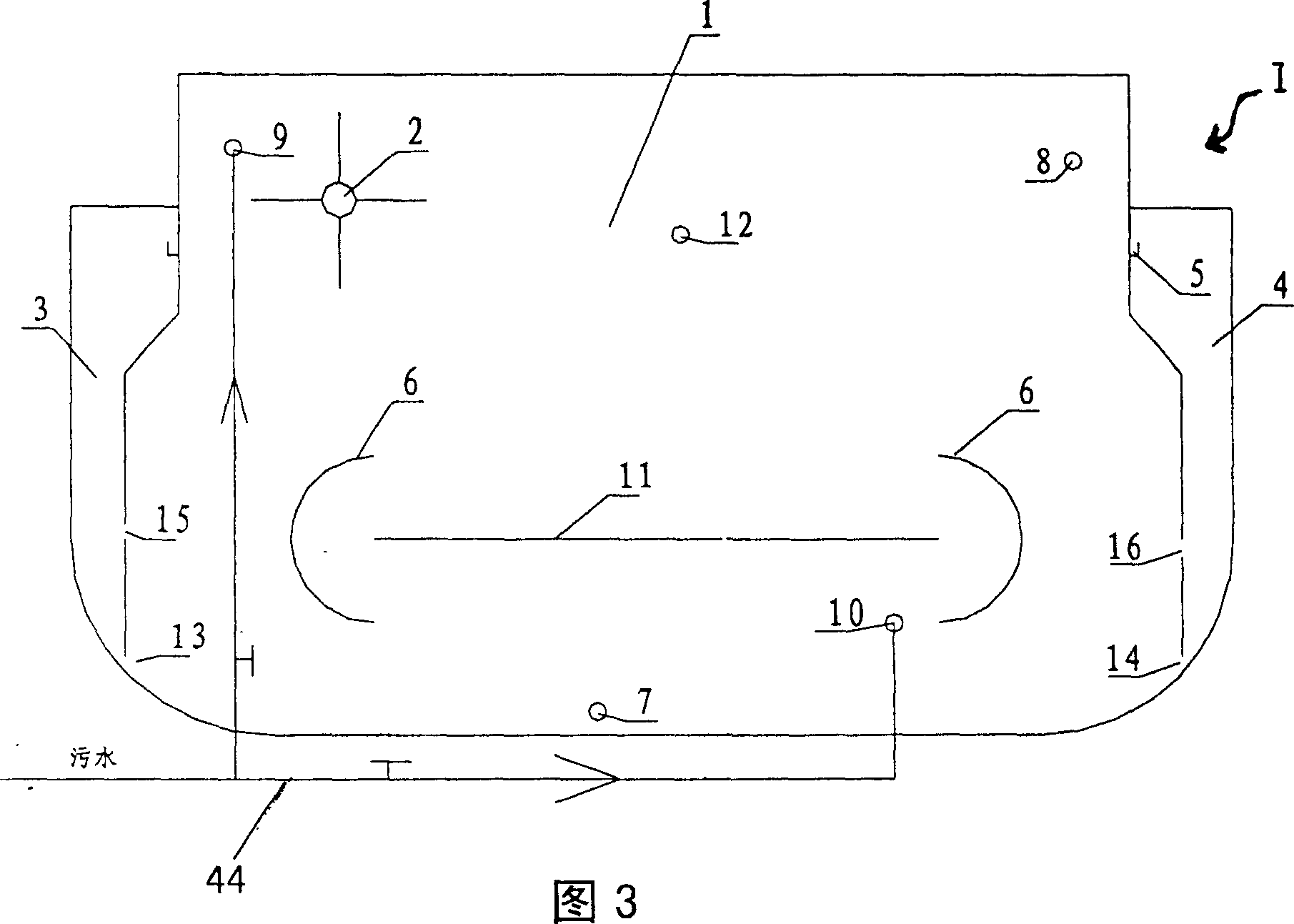

[0080] The average water quality characteristics of the sewage in the example of using the integrated sewage treatment system to treat domestic sewage are as follows: pH is 7.2, COD is 628mg / l, BOD 5 257mg / l, NH 3 -N is 59.1mg / l, TN is 79.4mg / l, TP is 4.mg / l 6, the intake concentrations of acetic acid, ammonia, hydrogen sulfide, ethanethiol, ethyl sulfide and styrene are: 8.88mg / m 3 , 8.93mg / m 3 , 0.025mg / m 3 , 0.18mg / m 3 , 0.081mg / m 3 and 36.69mg / m 3 ,

[0081] The sewage is pumped into the three-dimensional circulation integrated oxidation ditch sewage treatment reaction zone, and the treated sewage is discharged. The temperature of the three-dimensional integrated oxidation ditch changes with the seasons, but it is maintained at 12-27°C; the pH of the oxidation ditch mixture is maintained at 6.5-7.5 by adding NaHCO3 solution; the treatment capacity of the vertical-flow composite biological sludge reactor is reduced To control the SRT in 30-40 days; the sludge conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com