Self-heating high temperature aerobic treatment device for sewage sludge

A sewage sludge and aerobic treatment technology, applied in sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

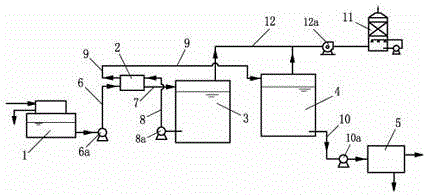

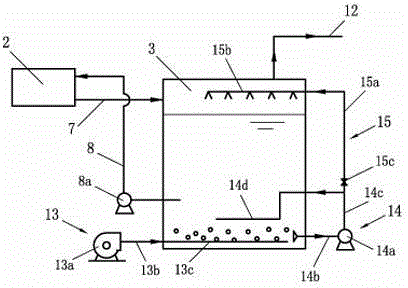

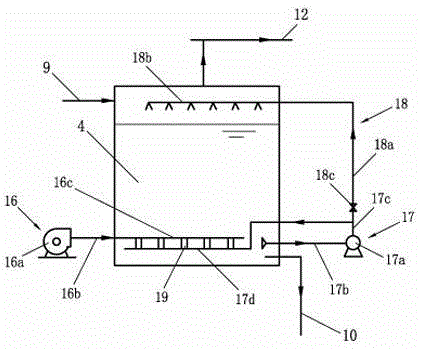

[0030] See attached picture. The present invention includes a pre-concentration device 1, a heat exchanger 2, an autothermal high-temperature aerobic digestion reactor 3, a denitrification reactor 4, and a sludge dehydration device 5;

[0031] The outlet end of the pre-thickening device 1 is communicated with the cold sludge inlet end of the heat exchanger 2 by the first mud delivery pipe 6, and the first mud delivery pipe 6 is provided with a first sludge pump 6a; the heat exchanger After the temperature rise of 2, the outlet end of the sludge is communicated with the self-heating high-temperature aerobic digestion reactor 3 through the second sludge delivery pipe 7; the outlet end of the self-heating high-temperature aerobic digestion reactor 3 is connected with the hot sludge The inlet end is connected by the third mud delivery pipe 8, and the third sludge delivery pipe 8 is provided with a second sludge pump 8a; the sludge outlet end of the heat exchanger 2 is cooled and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com