Sludge thickening device and sludge treatment method thereof

A sludge thickening and sludge technology, applied in dewatering/drying/concentrating sludge treatment, biological sludge treatment, etc., can solve the problems of high maintenance cost, poor sludge fluidity, secondary pollution of cleaning water, etc. To achieve the effect of convenient oxygenation and stirring, short residence time and low mechanical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

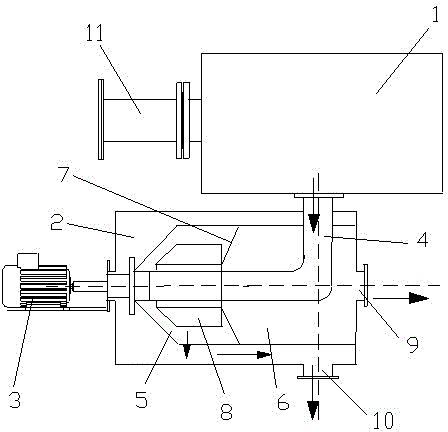

Embodiment 1

[0038] The remaining sludge produced by the urban sewage plant is selected, which is a mixed sludge composed of primary sludge and secondary sludge, and the specific gravity of the sludge is 1100kg / m 3 , enter the sludge thickening device of the present invention through the mud storage tank, and now the sludge thickening device selects the metal mesh cage 8 with a sieve aperture of 10mm, the motor 3 rotating speed adopts 1300 rpm, and the sludge flow rate is 230L / min, and the mixed sludge Centrifuge in the metal mesh cage 8 for 3 minutes, and the solid content of the sludge after concentration reaches 7%.

Embodiment 2

[0040] The excess sludge produced by urban sewage plants is selected, and the primary settling tank is canceled. The remaining sludge is activated sludge and secondary sludge, which has the characteristics of high water content and difficult dehydration. The specific gravity of sludge is 1060kg / m 3 , enter the sludge thickening device of the present invention through the mud storage tank, and now the sludge thickening device selects the metal mesh cage 8 with a sieve aperture of 5mm, the motor 3 rotating speed adopts 1650rpm, and the mud flow rate is 300L / min, and the secondary sedimentation is at The metal mesh cage 8 was centrifuged for 5 minutes, and the solid content of the sludge after concentration reached 6%.

Embodiment 3

[0042] The excess sludge produced by the urban sewage plant is mixed with pig manure, and the specific gravity reaches 1020kg / m 3 , sent to the sludge thickening device of the present invention, the sludge thickening device selects the metal mesh cage 8 with a sieve aperture of 7mm, the motor 3 rotating speed adopts 1500rpm, and the mud flow rate is 400L / min, and the mixed sludge is in the metal mesh cage 8 After centrifugation for 8 minutes, the solid content of the sludge after concentration reaches 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com