Method for pretreating sludge by high-pressure microwaves

A microwave treatment and pretreatment technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc. Reaction efficiency and anaerobic digestion performance, increased gas production, and high degree of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

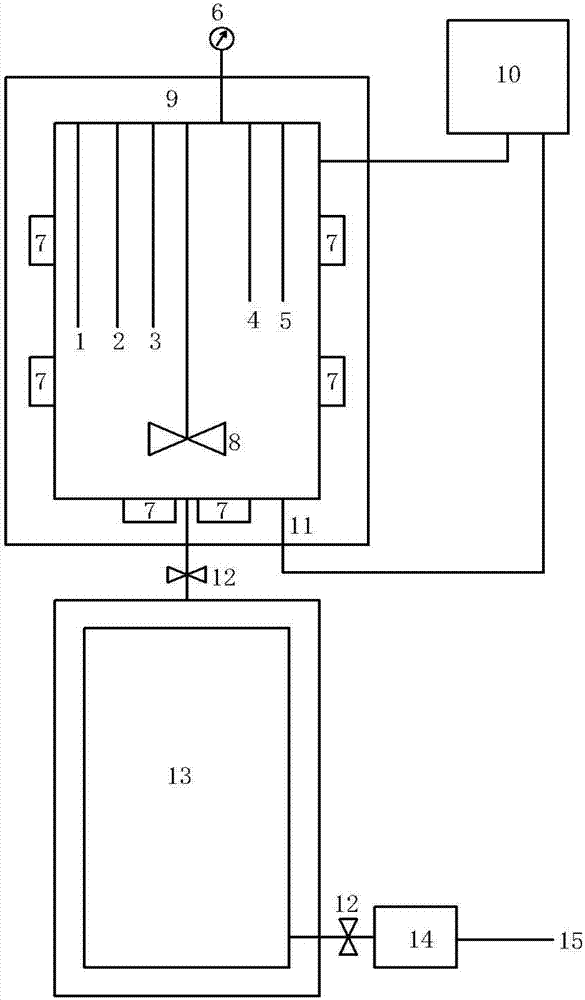

Image

Examples

Embodiment 1

[0044] For the residual sludge in the secondary sedimentation tank of a certain urban reclaimed water plant, Embodiment 1 provides a high-pressure microwave sludge pretreatment method, including the following steps:

[0045] (1) Concentrate the remaining sludge in the secondary sedimentation tank to a mud-water mixture with a concentration of 15-20g / L; add 5mol / L NaOH alkaline solution to adjust the pH to about 10;

[0046] (2) Put the sludge into the microwave reactor, turn on the microwave reactor, the frequency is 600MHz, and start the stirring device while radiating the sludge inside the device, stirring at a speed of 60rad / min, and press 10-20°C / min Heat the mud-water mixture to 80°C at the heating rate, turn off the microwave generator, temporarily stop the radiation heating, press H 2 o 2 / TS=0.2 mass ratio, add 30% hydrogen peroxide solution and stir slowly, restart the microwave generator, continue to heat the mud-water mixture at a heating rate of 10-20°C / min to 130°...

Embodiment 2

[0051] For the residual sludge in the secondary sedimentation tank of a certain urban reclaimed water plant, embodiment 2 provides a high-pressure microwave sludge pretreatment method, including the following steps:

[0052] (1) Concentrate the remaining sludge in the secondary sedimentation tank to a mud-water mixture with a concentration of 15-20g / L; add 5mol / L NaOH alkaline solution to adjust the pH to about 10;

[0053] (2) Put the sludge into the microwave reactor, turn on the microwave reactor, the frequency is 800MHz, and start the stirring device while radiating the sludge inside the device, stir at a speed of 60rad / min, and heat up at a rate of 15°C / min Heat the mud-water mixture at a high speed to 85°C, turn off the microwave generator, temporarily stop the radiation heating, press H 2 o 2 / TS=0.25 mass ratio, add 30% hydrogen peroxide solution and stir slowly, restart the microwave generator, continue to heat the mud-water mixture at a heating rate of 15°C / min to 1...

Embodiment 3

[0058] For the residual sludge in the secondary settling tank of a certain urban reclaimed water plant, embodiment 3 provides a high-pressure microwave sludge pretreatment method, including the following steps:

[0059] (1) Concentrate the remaining sludge in the secondary sedimentation tank to a mud-water mixture with a concentration of 15-20g / L; add 5mol / L NaOH alkaline solution to adjust the pH to about 10;

[0060] (2) Put the sludge into the microwave reactor, turn on the microwave reactor, the frequency is 400MHz, and start the stirring device while radiating the sludge inside the device, stir at a speed of 60rad / min, and heat up at a rate of 15°C / min Heat the mud-water mixture at a high speed to 75°C, turn off the microwave generator, temporarily stop the radiation heating, press H 2 o 2 / TS=0.15 mass ratio, add 30% hydrogen peroxide solution and stir slowly, restart the microwave generator, continue to heat the mud-water mixture at a heating rate of 15°C / min to 140°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com