High temperature carbonization system of sludge and carbonization process

A carbonization system and sludge technology, applied in the chemical industry, can solve the problems of groundwater resource pollution, water environment improvement, occupation, etc., and achieve the effect of reducing volume and weight and stabilizing heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and examples, but of course the following examples should not be construed as limiting the present invention.

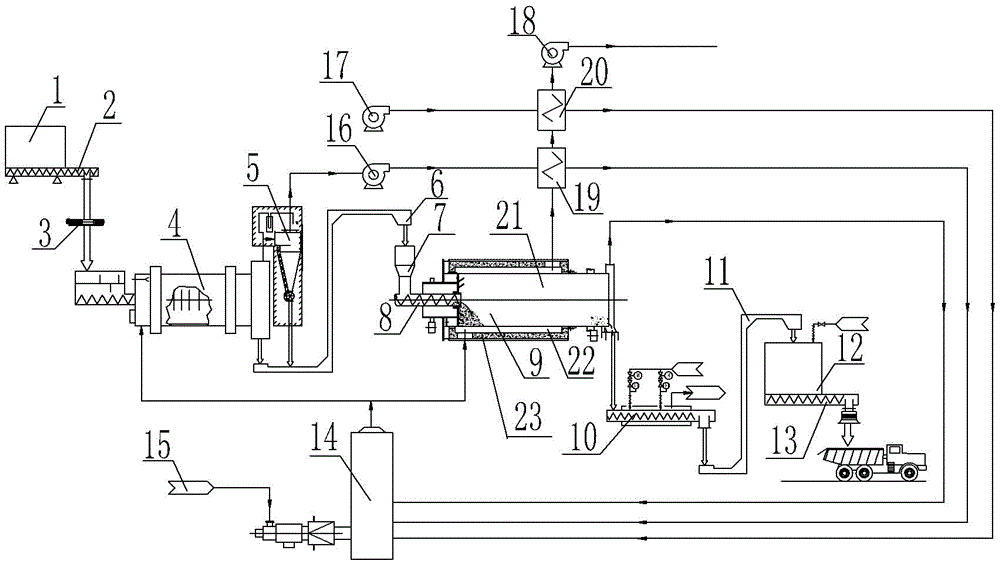

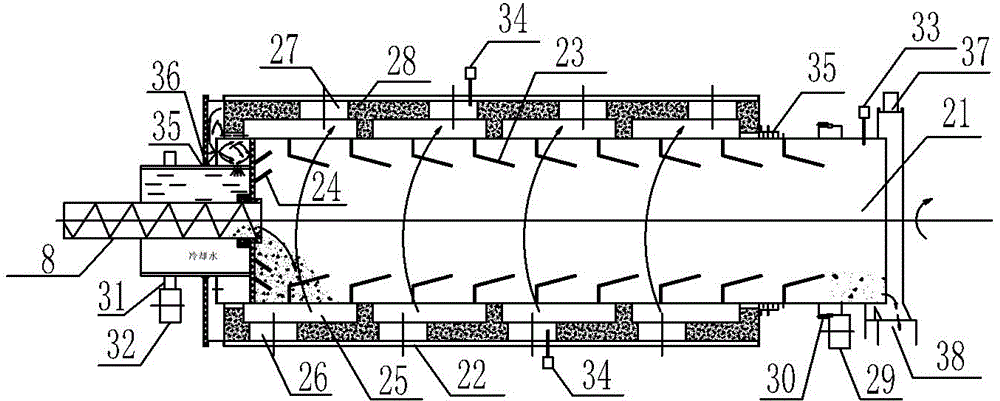

[0033] Such as figure 1 with figure 2 As shown, it is a sludge high-temperature carbonization system provided by an embodiment of the present invention, which includes a dewatered sludge supply unit, a dewatered sludge drying unit for drying the dewatered sludge provided by the dewatered sludge supply unit, and a A dry sludge carbonization unit for carbonizing the dried sludge, a heat cycle exchange unit, and a carbonization heating furnace 14 .

[0034] Wherein, the dewatered sludge supply unit includes a dewatered sludge storage bin 1 , a dewatered sludge screw conveyor 2 and a sludge screw pump 3 .

[0035] The dewatered sludge drying unit includes a dewatered sludge dryer 4 , a cyclone dust collector 5 , a dried sludge scraper conveyor 6 , and a dried slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com