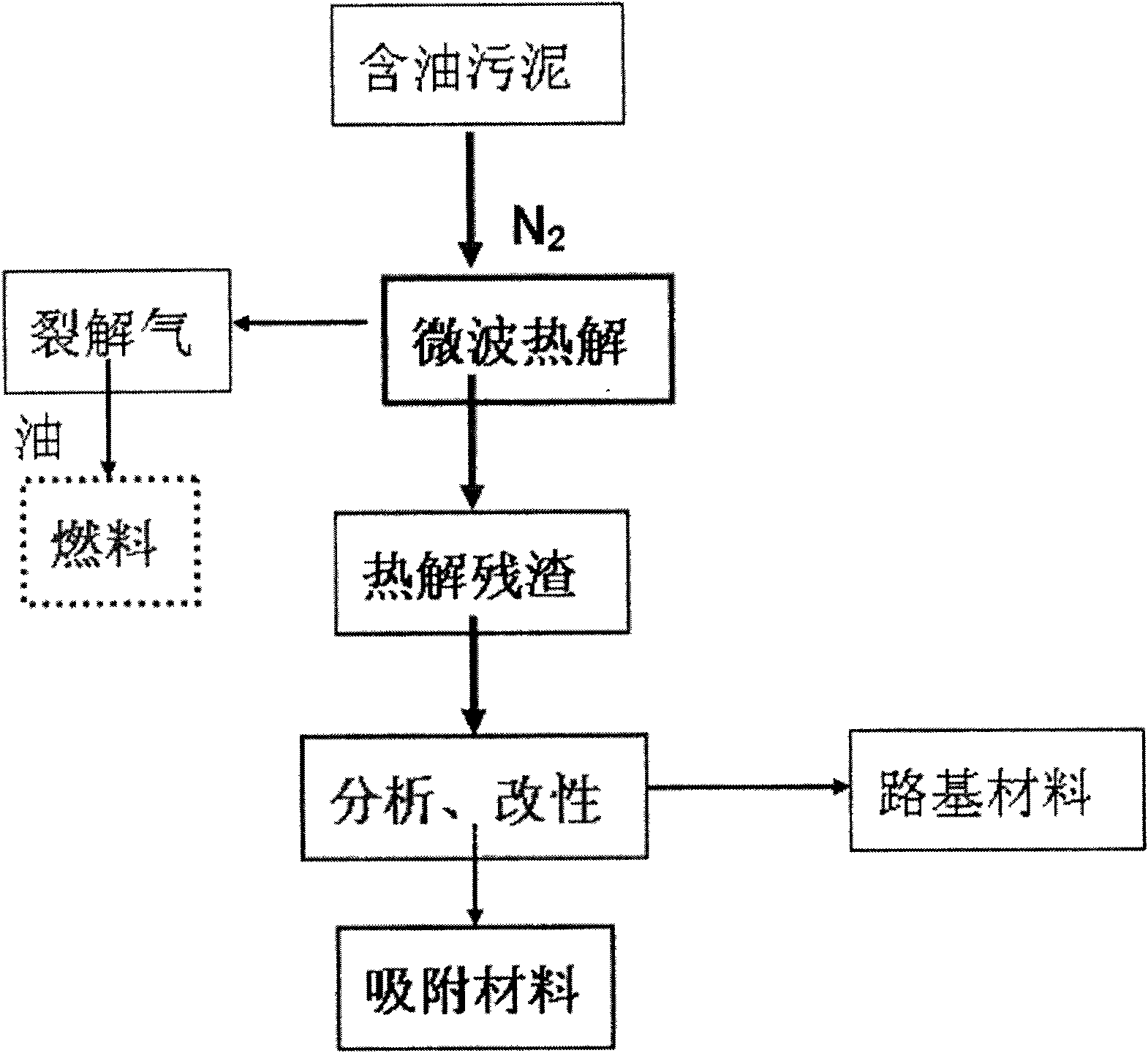

Resourceful treatment method and device for oil-containing sludge in oil fields by microwave pyrolysis

A treatment method and treatment device technology, applied in chemical instruments and methods, pyrolysis treatment of sludge, vaporization of by-products, etc., can solve problems such as excessive stacking sites, pollutants polluting the environment, etc., to solve environmental pollution and avoid danger The effects of waste discharge fees and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

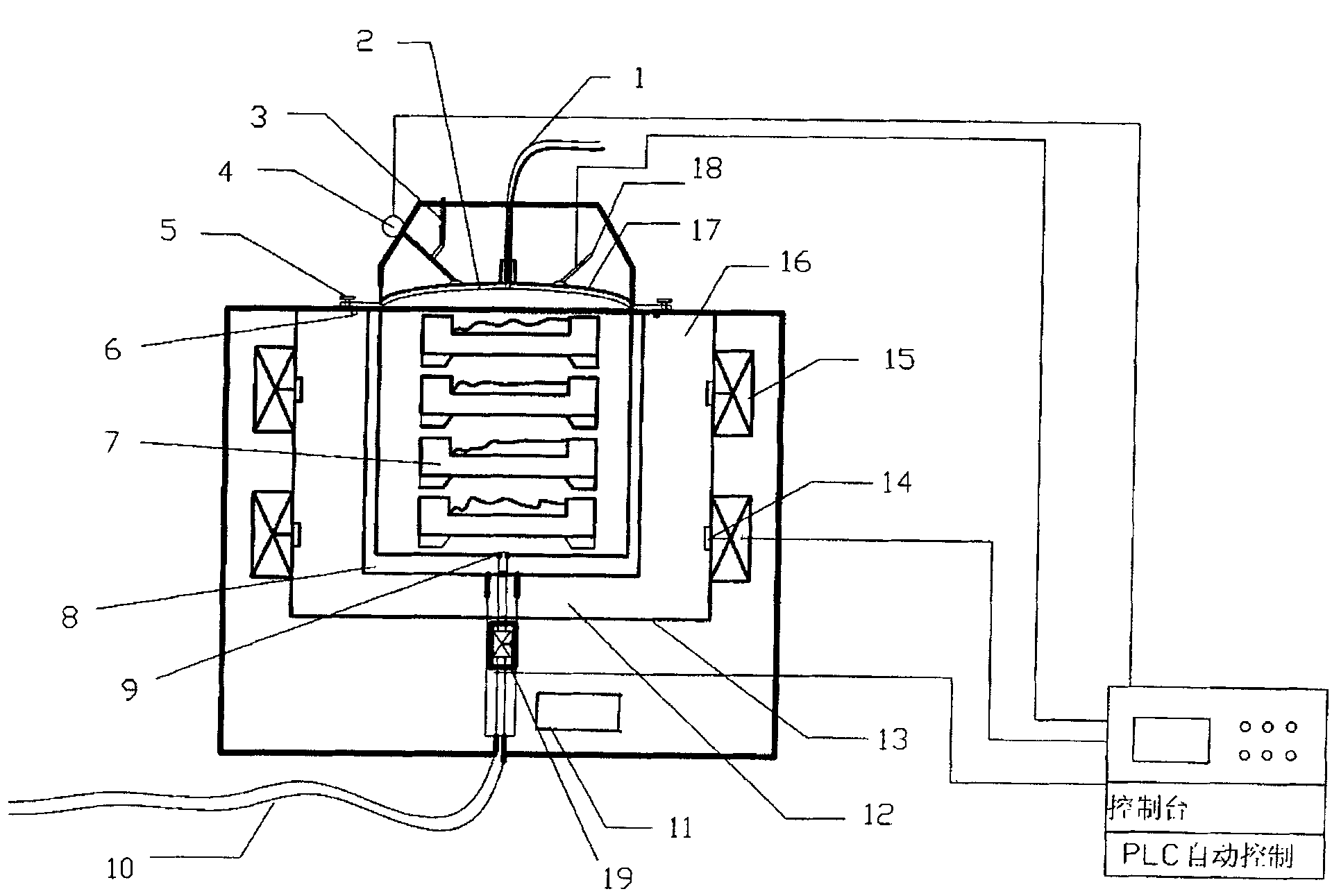

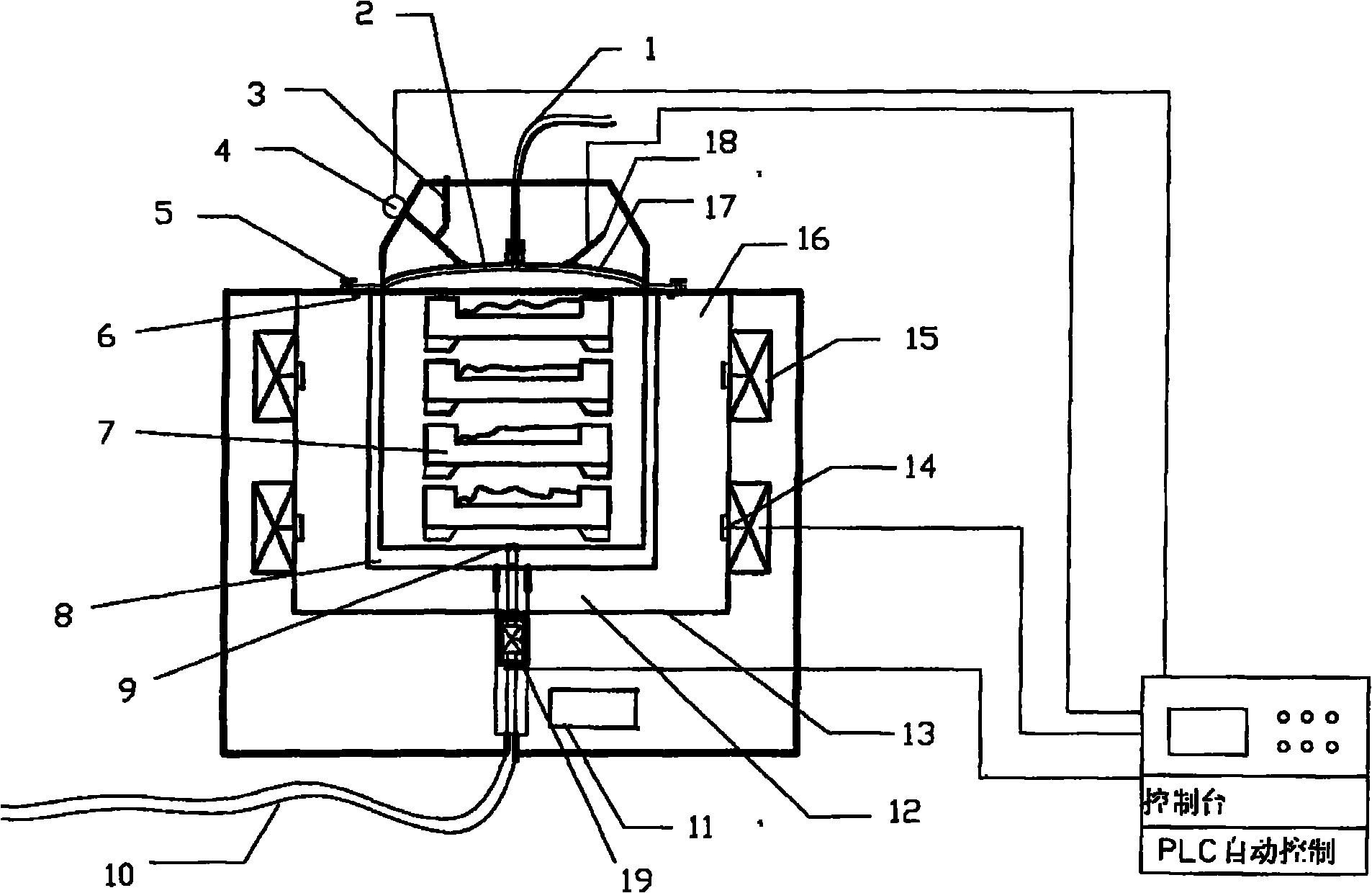

Method used

Image

Examples

Embodiment 1

[0033] In the storage yard of the oilfield joint station, the dried sludge with a moisture content of 8.0%, and the oil content of the dried sludge is 22.9%:

[0034] 1. The dried sludge is heated and reacted (ie, pyrolyzed) at 550°C for 4 hours, the oil content of the residue is 0.29%, and the oil recovery rate is 65.9%;

[0035] 2. The best activation conditions for nitric acid are: nitric acid concentration 45%, activation time 4h, mass parts liquid-solid ratio 4.5:1. The adsorption performance of the residue to phenol was measured, and its saturated adsorption capacity was 60.12mg / g.

Embodiment 2

[0037] In the storage yard of the oilfield joint station, the semi-dried sludge with a water content of 54.6%, and the oil content of the semi-dried sludge is 12.3%:

[0038] 1. The dried sludge is heated and reacted (ie pyrolysis) at 600℃ for 4 hours, the oil content of the residue is 0.21%, and the oil recovery rate is 60.9%;

[0039] 2. The optimal alkali activation conditions are as follows: activation temperature is 150°C, activation time is 3h, NaOH concentration is 30%, and mass ratio of alkali to solid is 2:1. The adsorption performance of the residue to phenol was measured, and its saturated adsorption capacity was 47.04mg / g.

Embodiment 3

[0041] The bottom sludge of the settling tank of the oilfield joint station has a water content of 65% and an oil content of 10.8%:

[0042] 1. The dried sludge is heated and reacted (ie pyrolysis) at 600℃ for 4 hours, the oil content of the residue is 0.25%, and the oil recovery rate is 64.3%;

[0043] 2. The best activation conditions for nitric acid are: nitric acid concentration 45%, activation time 4h, mass parts liquid-solid ratio 4.5:1. The adsorption performance of the residue to phenol was measured, and its saturated adsorption capacity was 51.96mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com