Indirect heating and thermal desorption treatment device and method for oily solid waste

A processing device and thermal desorption technology, applied in the field of desorption and separation to achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

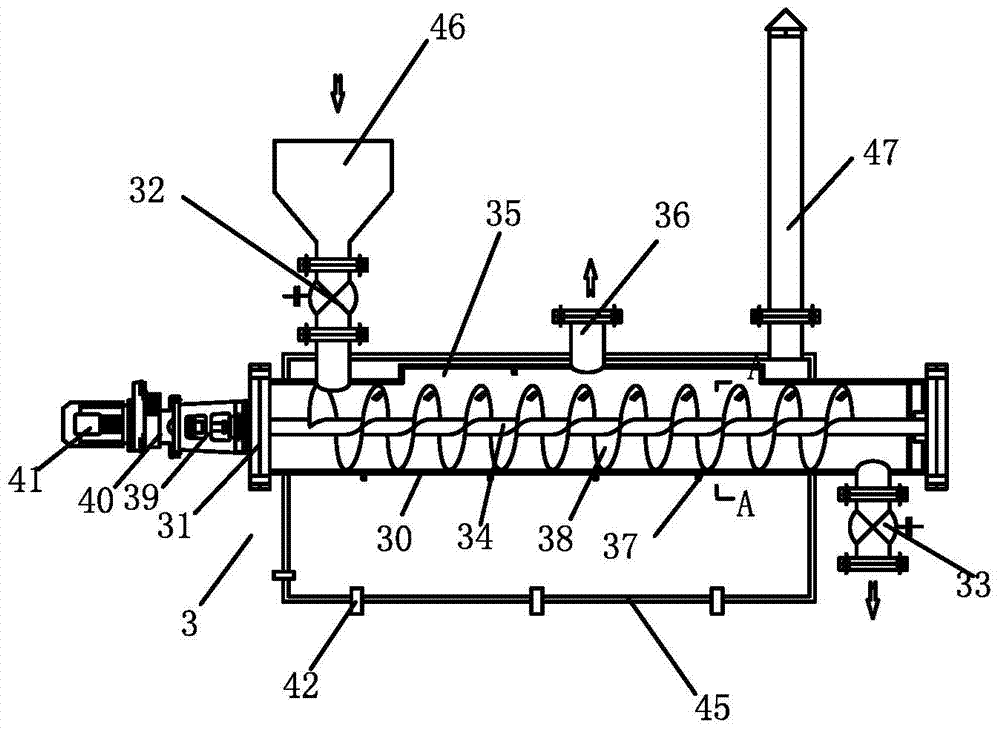

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

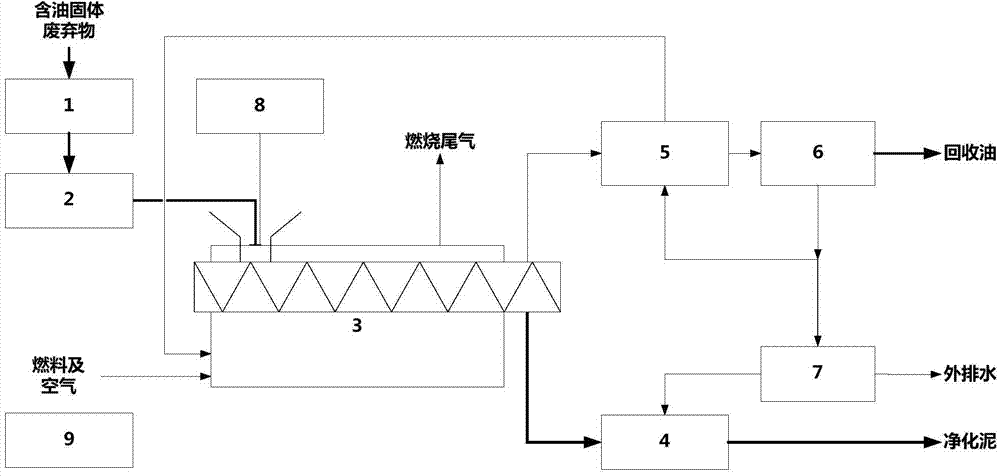

[0030] Such as figure 1 As shown, the indirect heating thermal desorption treatment device for oily solid waste in the present invention includes a feed pretreatment unit 1, a feed metering and protection unit 2, an indirect heating and thermal desorption unit 3, a desorption steam separation and purification unit 5, a circulation Water treatment and oil collection unit 6 , slag post-treatment unit 4 , sewage purification unit 7 , nitrogen protection unit 8 and automatic control unit 9 .

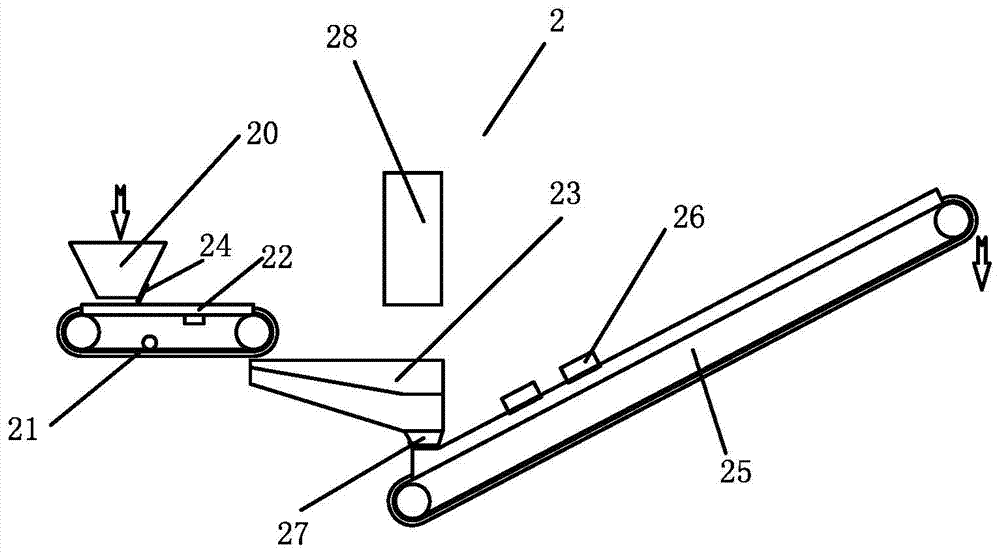

[0031] Feed material pretreatment unit 1 is equipped with a feed stockyard for classified acceptance and storage of oily solid waste. Obvious sundries such as packaging bags are removed in the feed stockyard, and then the mixing and homogenization of various types of oil sludge is completed by turning and throwing machinery For the dispersing operation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com