Resource treating method for oil-containing sludge

A treatment method and resource-based technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

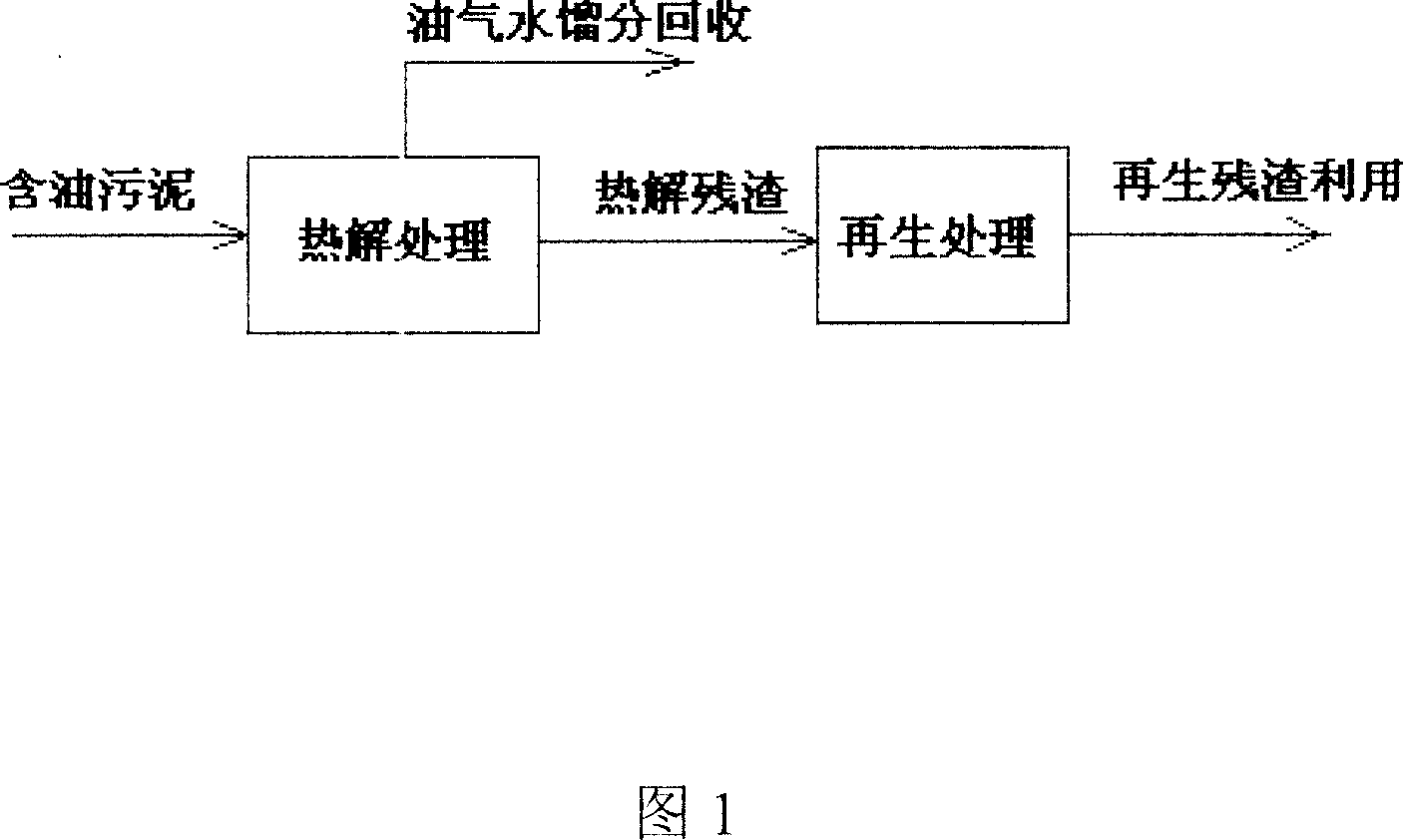

Image

Examples

Embodiment 1

[0027] Oil field heavy oil sewage treatment press filter dewatered sludge, the mud cake is naturally dried to obtain dry sludge with a moisture content of 4.7%, and the oil content of the dry sludge is 12%:

[0028] 1. The dry sludge is heated and pyrolyzed under the condition of 600°C for 3 hours, the oil content of the residue is 0.004%, the oil recovery rate is 13.8%, and the gas production rate is 80 cubic meters / ton;

[0029] 2. After adding sulfuric acid to the residue with sulfuric acid at a ratio of 1:2 of the chemical equivalent of aluminum salt and treating it at normal temperature, a mixed solution containing 11.5% aluminum oxide is obtained, which has a good coagulation effect for sewage treatment. Compared with commercial polyaluminium, the addition amount to achieve the same coagulation effect is roughly three times that of commercial polyaluminium.

Embodiment 2

[0031] The tank bottom sludge of the oil-water settling tank in the oil field is heated and dried to obtain dry sludge with a moisture content of 1.7%, and the oil content of the dry sludge is 27.6%:

[0032] 1. The dry sludge is heated and reacted (ie, pyrolyzed) in a closed environment at 550°C for 2 hours, the oil content of the residue is 0.007%, the oil recovery rate is 31.7%, and the gas production rate is 65 cubic meters / ton;

[0033] 2. Determining the adsorption performance of the residue to asphalt, its saturated adsorption capacity is 43.7mg / g (the saturated adsorption capacity of activated clay supplemented and refined by commercial lubricating oil is 44.3mg / g), and the adsorption performance of the activated clay used for supplementary refining of lubricating oil quite.

Embodiment 3

[0035] The dewatered sludge of oil refinery sewage treatment has a water content of 82% and an oil content of 7.6%:

[0036] 1. Sealed heating reaction (i.e. pyrolysis) at 550°C for 3 hours, the oil content of the residue is 0.009%, the oil recovery rate is 9.7%, and the gas production rate is 20 cubic meters / ton;

[0037] 2. After adding hydrochloric acid to the residue with hydrochloric acid at a ratio of 1:2 of the chemical equivalent of aluminum salt and treating it at normal temperature, a mixed solution containing 23.7% aluminum oxide is obtained, which has a good coagulation effect for sewage treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com