High-temperature melting treatment system and method for sludge

A high-temperature melting and treatment system technology, applied in combustion methods, separation methods, pyrolysis treatment of sludge, etc., can solve problems such as dioxin pollution, and achieve the effect of realizing emissions and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

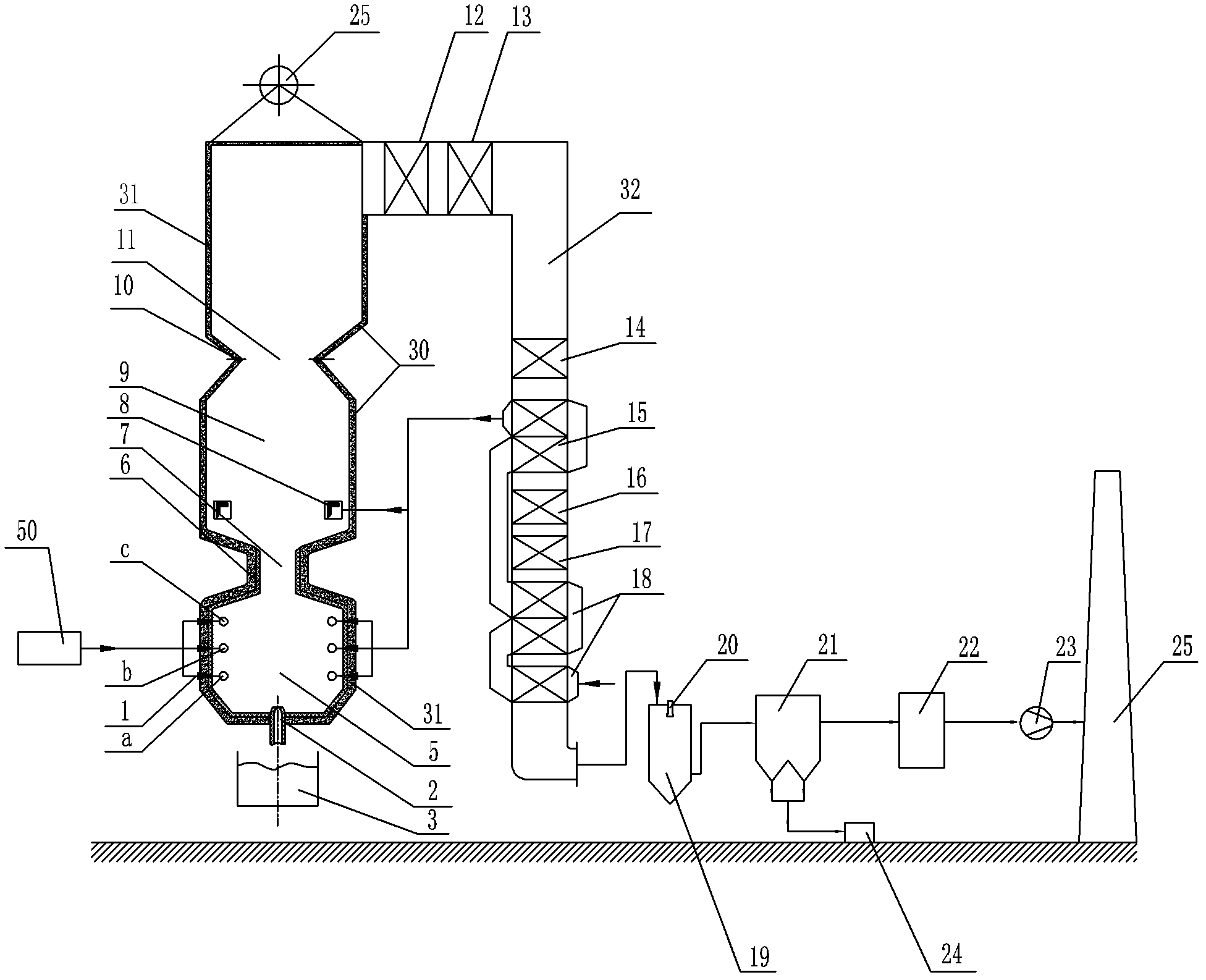

[0036] Specific implementation mode one: combine figure 1 Describe this embodiment, the high-temperature melting treatment system of sludge in this embodiment, the system includes a ball mill 50 and a high-temperature melting treatment device for sludge, and the high-temperature melting treatment device for sludge includes a furnace body, an overflow slagging Port 2, slag pool 3, membrane water wall 30, steam drum 25, high temperature superheater 12, low temperature superheater 13, high temperature economizer 14, high temperature air preheater 15, SCR denitrification system 16, low temperature economizer 17. Low temperature air preheater 18, sprayer 20, flue gas quenching tower 19, bag filter 21, ash bin 24, flue gas wet desulfurization system 22, induced draft fan 23, chimney 25 and flue 32;

[0037] The furnace body is composed of an integrated melting chamber 5, a contraction section flue gas outlet 7 and a secondary combustion chamber 9 from bottom to top. The lower part o...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 , Figure 3-Figure 5 Explain, the high-temperature melting treatment method of the sludge of the present embodiment, the high-temperature melting treatment method of the sludge is completed by the following steps:

[0039] Step 1, the sludge is firstly dried, and the moisture content of the dried sludge is less than 10%;

[0040] Step 2, sending the dried sludge into the ball mill 50 to be ground into a powder with a particle size less than 100 μm;

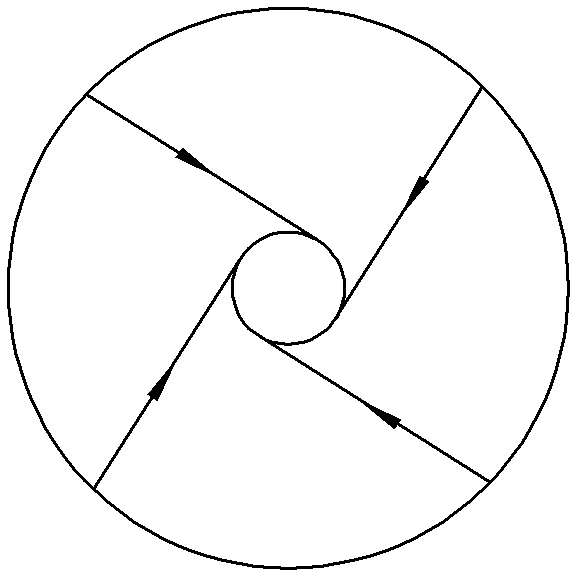

[0041] Step 3: first heat the primary air to 150-180°C through the low-temperature air preheater 18, and then heat it to 350-400°C through the high-temperature air preheater 15; after that, pass the dried sludge powder obtained in step 2 into the The feed port 1 and the primary air are sent tangentially into the melting chamber 5 to form a vortex combustion to a high-temperature melting state. When the melting chamber 5 is in a high-temperature melting state, the temp...

specific Embodiment approach 3

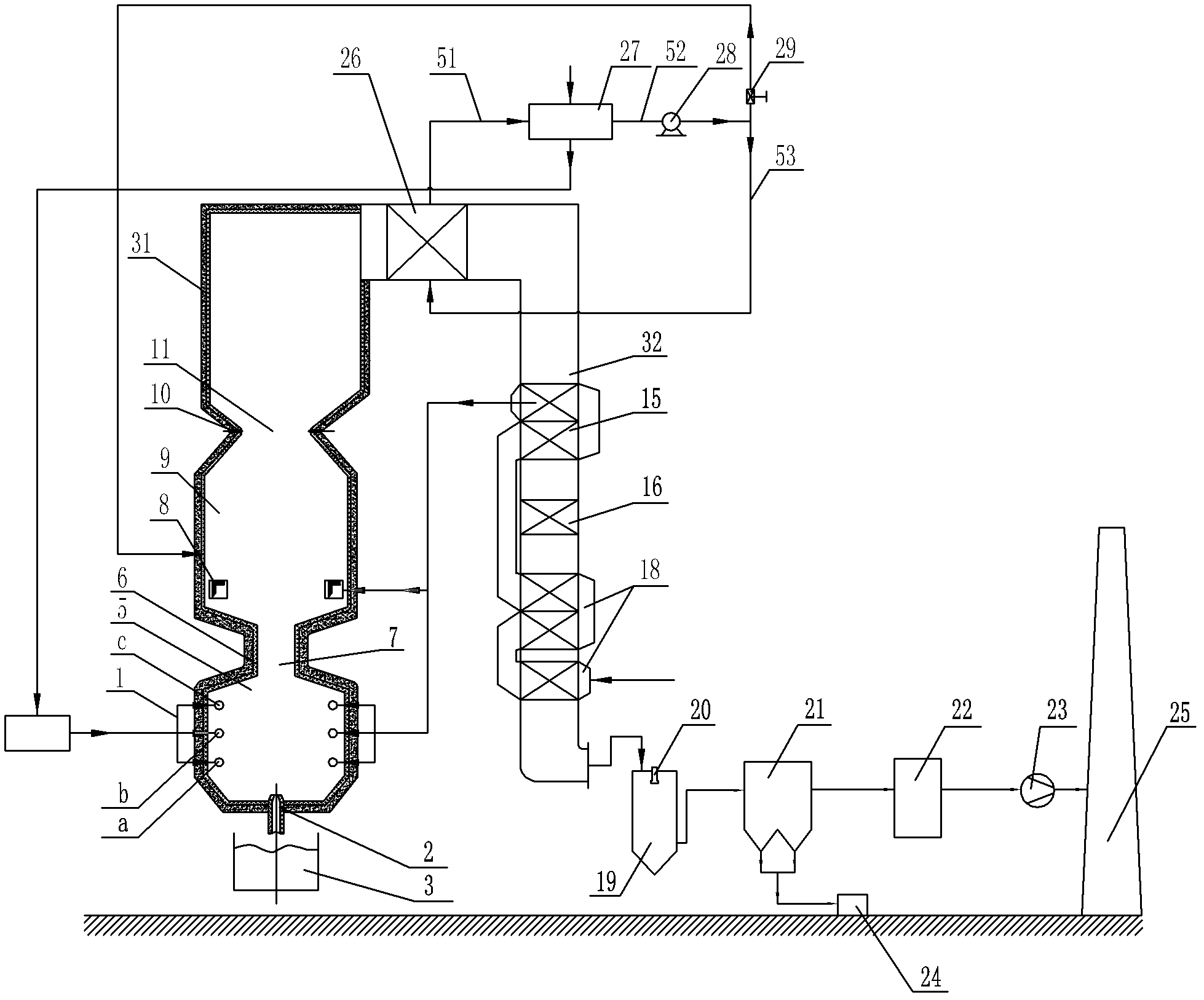

[0045] Specific implementation mode three: combination figure 2 Explain, the high-temperature melting processing system of sludge in this embodiment, the system includes a ball mill 50 and a high-temperature melting processing device for sludge, and the high-temperature melting processing device for sludge includes a furnace body, an overflow slagging outlet 2, Slag pool 3, high temperature air preheater 15, SCR denitrification system 16, low temperature air preheater 18, sprayer 20, flue gas quenching tower 19, bag filter 21, ash bin 24, flue gas wet desulfurization system 22, Induced fan 23, chimney 25 and flue 32;

[0046] The furnace body is composed of an integrated melting chamber 5, a shrinkage section flue gas outlet 7 and a secondary combustion chamber 9 from bottom to top. The lower part of the side wall of the melting chamber 5 is provided with a feed port 1, and the ball mill 50 is arranged outside the furnace body. The outlet of the ball mill 50 is in communicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com