Process for treating excess sludge

A technology for excess sludge and sludge, applied in the field of water treatment, can solve the problems of residence time as long as 20-30d, low digestion rate, low treatment efficiency, etc., to achieve reduction, increase production, and improve removal rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

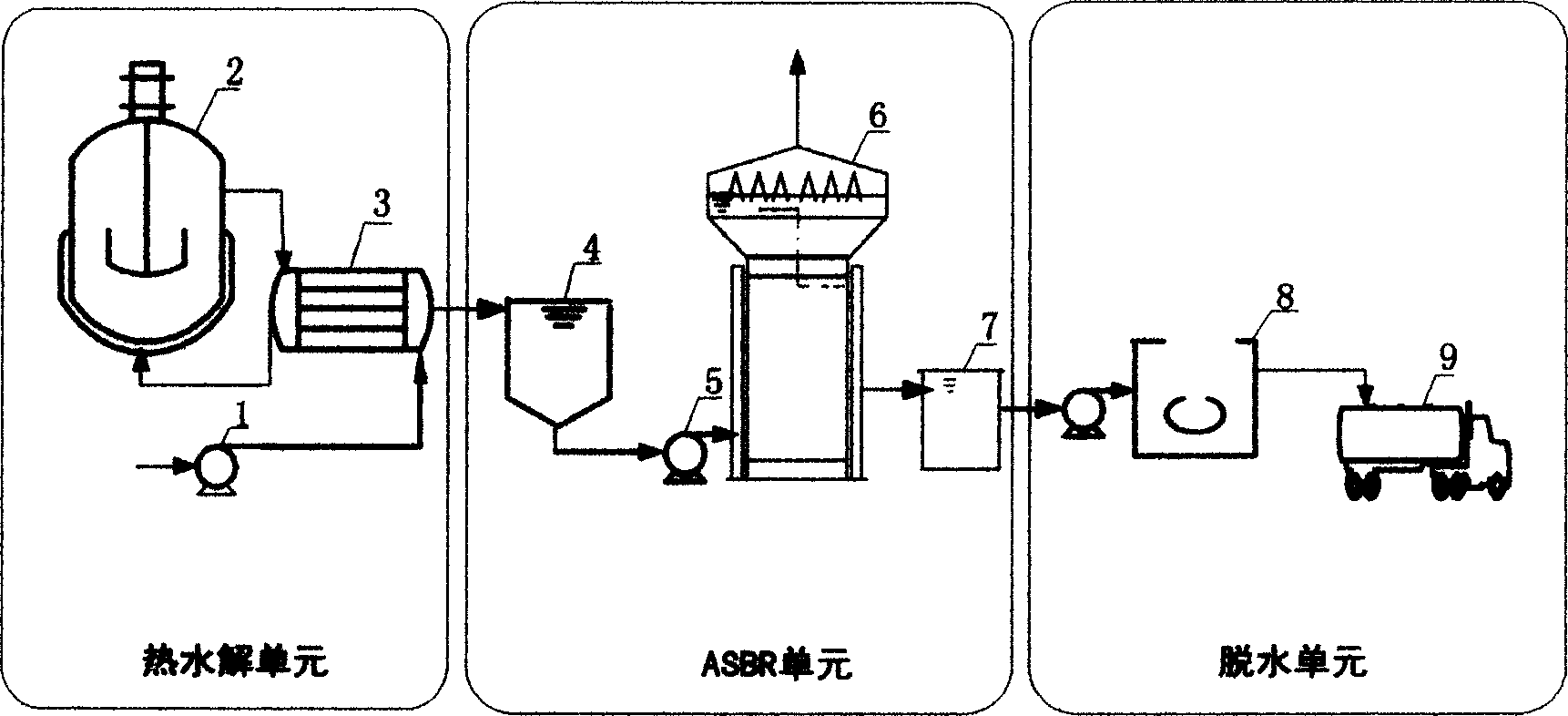

[0009] The invention provides a method for treating excess sludge that can realize resource utilization and volume reduction treatment. The method is through three processing steps of thermal hydrolysis treatment, anaerobic digestion and dehydration in a sequencing batch anaerobic reactor (ASBR):

[0010] 1) Using an autoclave as a reactor, thermal hydrolysis is carried out at a temperature range of 110° C. to 190° C., and the thermal hydrolysis time is 15 to 75 minutes. With the different properties of sludge, the optimal thermal hydrolysis conditions are also different. After the sludge is pretreated by thermal hydrolysis, the microbial flocs disintegrate, the microbial cells rupture, and the organic matter (such as protein, fat and carbohydrates) of the cells is released and further hydrolyzed, so the anaerobic digestion performance of the sludge is also improved. Thereby improving the efficiency of subsequent anaerobic digestion and increasing the gas production of methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com