Method for using blast furnace slag to produce micro-crystalline light brick

A blast furnace slag, lightweight brick technology, applied in the field of engineering materials, can solve the problem that the sensible heat and latent heat of high-temperature slag are difficult to be effectively recycled, waste water, corrosive hot steam heat cannot be recovered, and water resources cannot be recycled and repeated. Use and other issues to achieve the effects of good thermal insulation, high strength and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

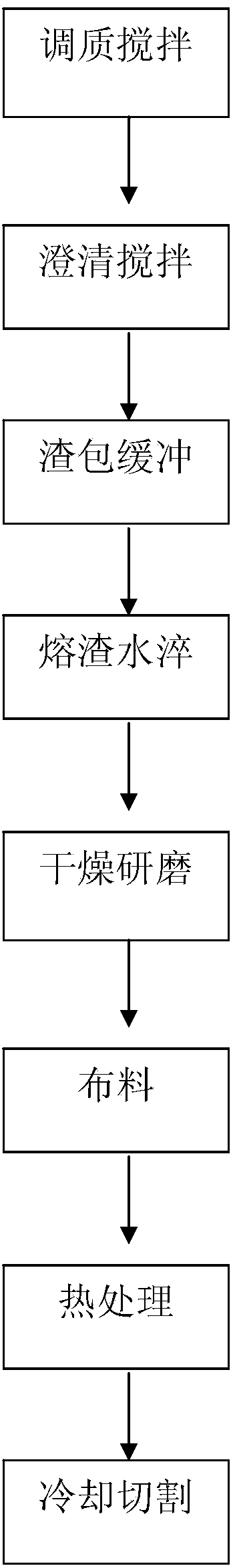

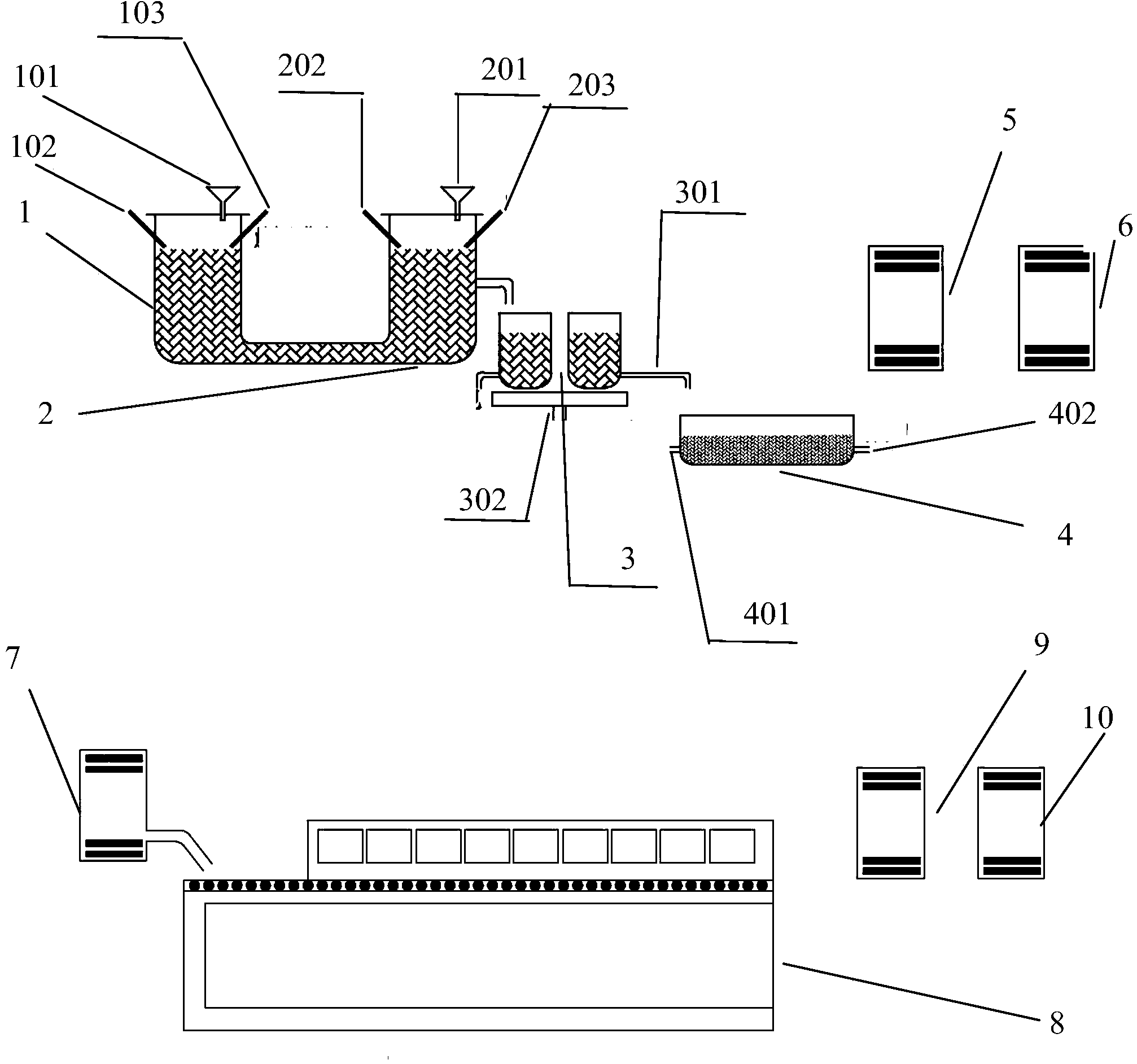

[0083] The present invention provides a process for producing microcrystalline lightweight bricks using blast furnace slag, comprising the following steps:

[0084] (1) The 1400-1580°C slag flowing out of the blast furnace is heated and kept in a mixed iron furnace and transferred to the composition quenching and tempering stirring tank;

[0085] (2) Add the conditioning agent into the component conditioning mixing tank, blow the inert gas from the top to mix the components evenly, and spray the steel by-product gas to keep the slag at 1400-1580°C for 1 hour;

[0086] (3) The slag enters the slag clarification tank through the slag port at the bottom of the component quenching and tempering mixing tank, and antimony trioxide is added to remove various impurities and bubbles in the slag to make the composition uniform, and the iron and steel by-product gas is injected, Keep the molten slag at 1400-1580°C;

[0087] (4) The molten slag enters the slag bag through the slag port a...

Embodiment 2

[0095] The present invention provides a process for producing microcrystalline lightweight bricks using blast furnace slag, comprising the following steps:

[0096] (1) The 1400-1580°C slag flowing out of the blast furnace is heated and kept in a mixed iron furnace and transferred to the composition quenching and tempering stirring tank;

[0097] (2) Add the component modifying agent into the component tempering stirring tank, blow the inert gas from the top to mix the components evenly, and spray the steel by-product gas to keep the slag at 1400-1580°C for 1 hour;

[0098] (3) The slag enters the slag clarification tank through the slag port at the bottom of the composition-conditioning and tempering stirring tank, adding clarifiers to remove various impurities and air bubbles in the slag to make its composition uniform, and spraying steel by-product gas to make the slag The slag is kept at 1400-1580°C;

[0099] (4) The molten slag enters the slag bag through the slag port a...

Embodiment 3

[0107] The present invention provides a process for producing microcrystalline lightweight bricks using blast furnace slag, comprising the following steps:

[0108] (1) The 1400-1580°C slag flowing out of the blast furnace is heated and kept in a mixed iron furnace and transferred to the composition quenching and tempering stirring tank;

[0109] (2) Add the component modifying agent into the component tempering stirring tank, blow the inert gas from the top to mix the components evenly, and spray the steel by-product gas to keep the slag at 1400-1580°C for 1 hour;

[0110] (3) The slag enters the slag clarification tank through the slag port at the bottom of the composition-conditioning and tempering stirring tank, adding clarifiers to remove various impurities and air bubbles in the slag to make its composition uniform, and spraying steel by-product gas to make the slag The slag is kept at 1400-1580°C;

[0111] (4) The molten slag enters the slag bag through the slag port a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com