Continuous advanced treatment system of heavy metal ion-containing tail water and treatment method

A heavy metal ion and advanced treatment technology, applied in ion exchange water/sewage treatment, magnetic field/electric field water/sewage treatment, organic fertilizer, etc., to achieve the effect of less equipment investment, fast treatment speed and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Pretreatment: Primary filtration of tail water with filter membrane;

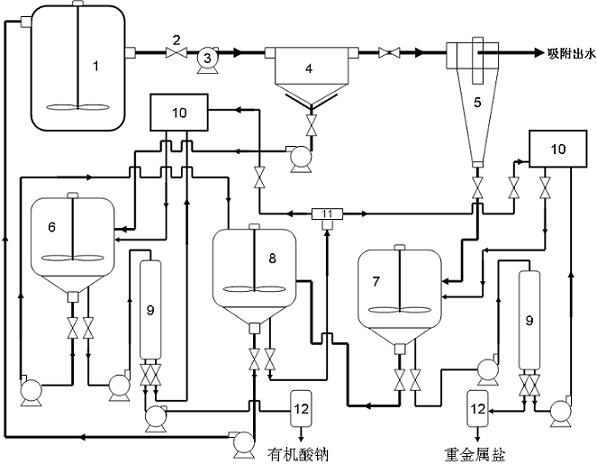

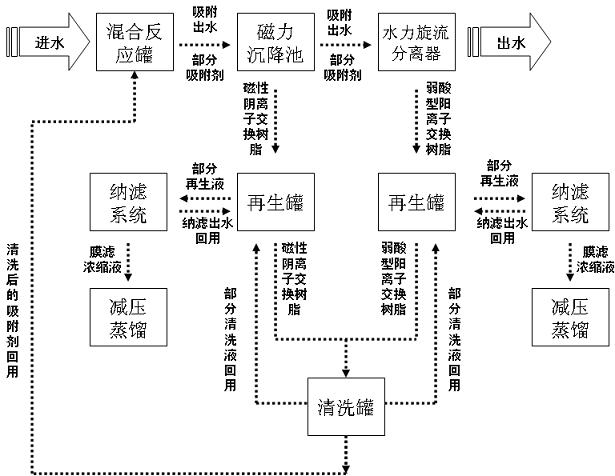

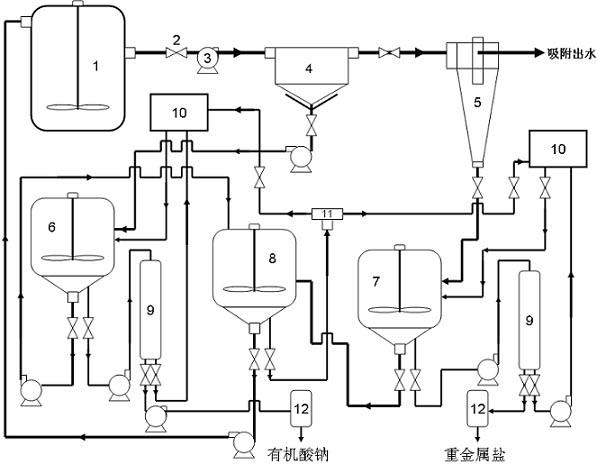

[0036] (2) Put 100mL of magnetic anion exchange resin MD201 and 100mL of weak acid type cation exchange resin D113 into mixing reaction tank 1 (diameter of mixing reaction tank is 0.2m, height is 0.3m), and the stirring speed of the built-in stirrer is 120r / min. The tail water is continuously inflow / outflow at a flow rate of 5000mL / h, and passes through the flow control valve 2 and the peristaltic pump 3 successively;

[0037] (3) The effluent from the mixing reaction tank 1 carries part of the magnetic anion exchange resin and weakly acidic cation exchange resin into the magnetic sedimentation tank 4, and the magnetic anion exchange resin quickly settles to the bottom of the tank under the action of magnetic force;

[0038] (4) The weakly acidic cation exchange resin enters the gravity hydrocyclone 5 for solid-liquid separation with the inertia of the water flow, and the effluent overflows from ...

Embodiment 2

[0045] Other operating conditions remain unchanged, but the tail water inflow / outflow flow rate in step (2) is adjusted to 7500mL / h, except for COD in the adsorbed effluent Cr Rising to 32mg / L, copper ion rising to 0.014mg / L, other results are identical with embodiment 1.

Embodiment 3

[0047] The steps are the same as in Example 1, but the desorbent in step (7) is changed to a 15% NaCl solution by weight percentage, and the desorbent in step (8) is changed to 1% HCl by weight, and other operating conditions are unchanged , its implementation result is basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com