Method for extracting gold from waste circuit boards

A waste circuit board and immersion gold technology, which is applied in the field of industrial waste recycling, can solve a large number of problems with high equipment requirements, and achieve the effects of avoiding environmental pollution, simple equipment, and strong practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

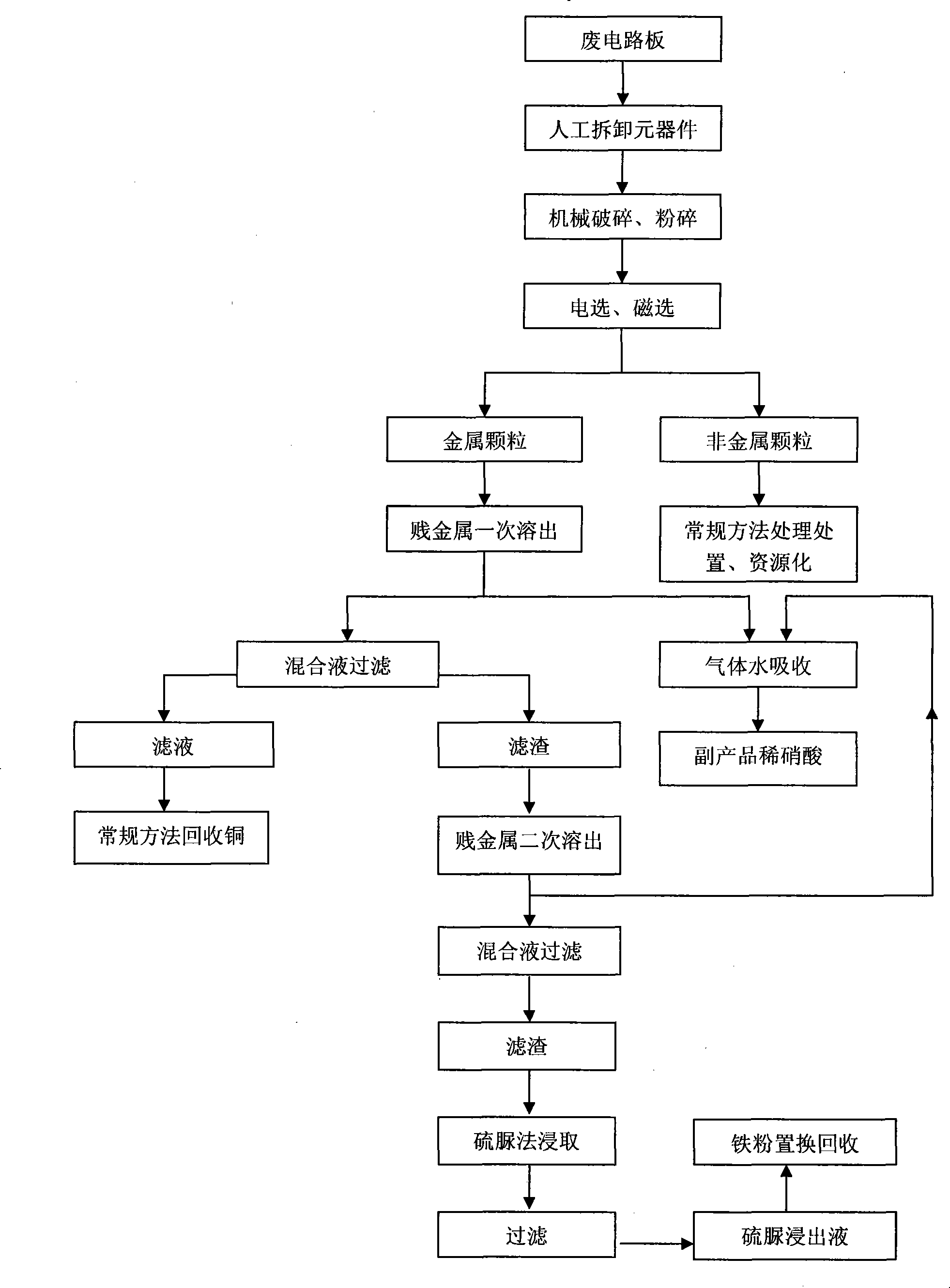

Image

Examples

Embodiment 1

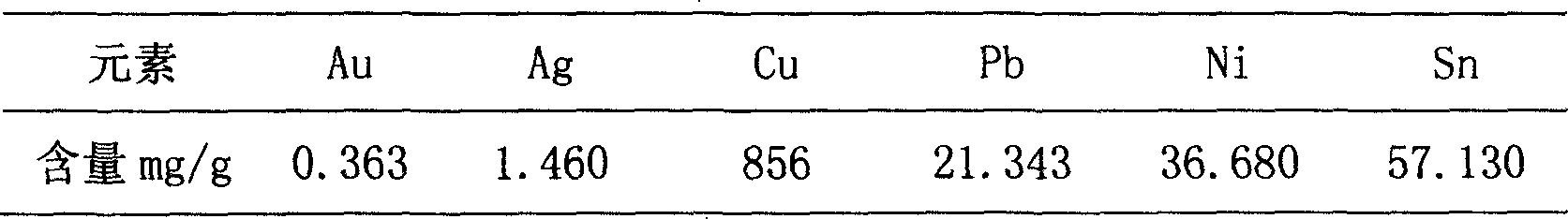

[0038] Using waste circuit boards as raw materials, after pretreatment such as crushing and sorting, the metal particle components were analyzed by microwave digestion ICP-AES method. In view of the very high copper content, the national standard method (iodometric method) was used for analysis. The results are shown in Table 1.

[0039] Table 1 shows the content of main metal elements in waste circuit boards

[0040]

[0041]Pour the metal particles, nitric acid and sulfuric acid mixed acid solution (the concentration of nitric acid is 1.0 mol / L, the concentration of sulfuric acid is 2.5 mol / L) into the reactor, the solid-liquid ratio of the two is 1:10, stir and react at a constant temperature of 55 ° C for 1.5 h , the stirring speed is 500r / min, and a small amount of nitrogen oxide produced in the reaction is absorbed by water to obtain dilute nitric acid as a by-product. The reacted mixture is cooled and filtered, and the filtrate adopts conventional methods to recover...

Embodiment 2

[0043] Pour the metal particles, nitric acid and sulfuric acid mixed acid solution (the concentration of nitric acid is 1.0 mol / L, the concentration of sulfuric acid is 3 mol / L) into the reactor, the solid-liquid ratio of the two is 1:10, stir and react at a constant temperature of 60 ° C for 1.5 h, The stirring speed is 500r / min, and a small amount of nitrogen oxide produced in the reaction is absorbed by water to obtain dilute nitric acid as a by-product. The reacted mixture is cooled and filtered, and the filtrate adopts conventional methods to recover copper, and the filter residue and dilute nitric acid solution enter the reactor for secondary dissolution of base metals, the solid-liquid ratio is 1:10, the nitric acid concentration is 1.0mol / L, and the reaction is stirred at room temperature 0.5h, the stirring speed is 300r / min. Also use water to absorb a small amount of nitrogen oxides produced by the reaction, cool and filter the reacted mixture, wash and dry the residu...

Embodiment 3

[0045] Using waste circuit boards as raw materials, after pretreatment such as crushing and sorting, the metal particle components were analyzed by microwave digestion ICP-AES method. In view of the very high copper content, the national standard method (iodometric method) was used for analysis. The results are shown in Table 1. Pour the metal particles, nitric acid and sulfuric acid mixed acid solution (the concentration of nitric acid is 1.0 mol / L, the concentration of sulfuric acid is 2.5 mol / L) into the reactor, the solid-liquid ratio of the two is 1:10, stir and react at a constant temperature of 60°C for 2 hours, The stirring speed is 500r / min, and a small amount of nitrogen oxide produced in the reaction is absorbed by water to obtain dilute nitric acid as a by-product. The reacted mixture is cooled and filtered, and the filtrate adopts conventional methods to recover copper, and the filter residue and dilute nitric acid solution enter the reactor for secondary elution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com