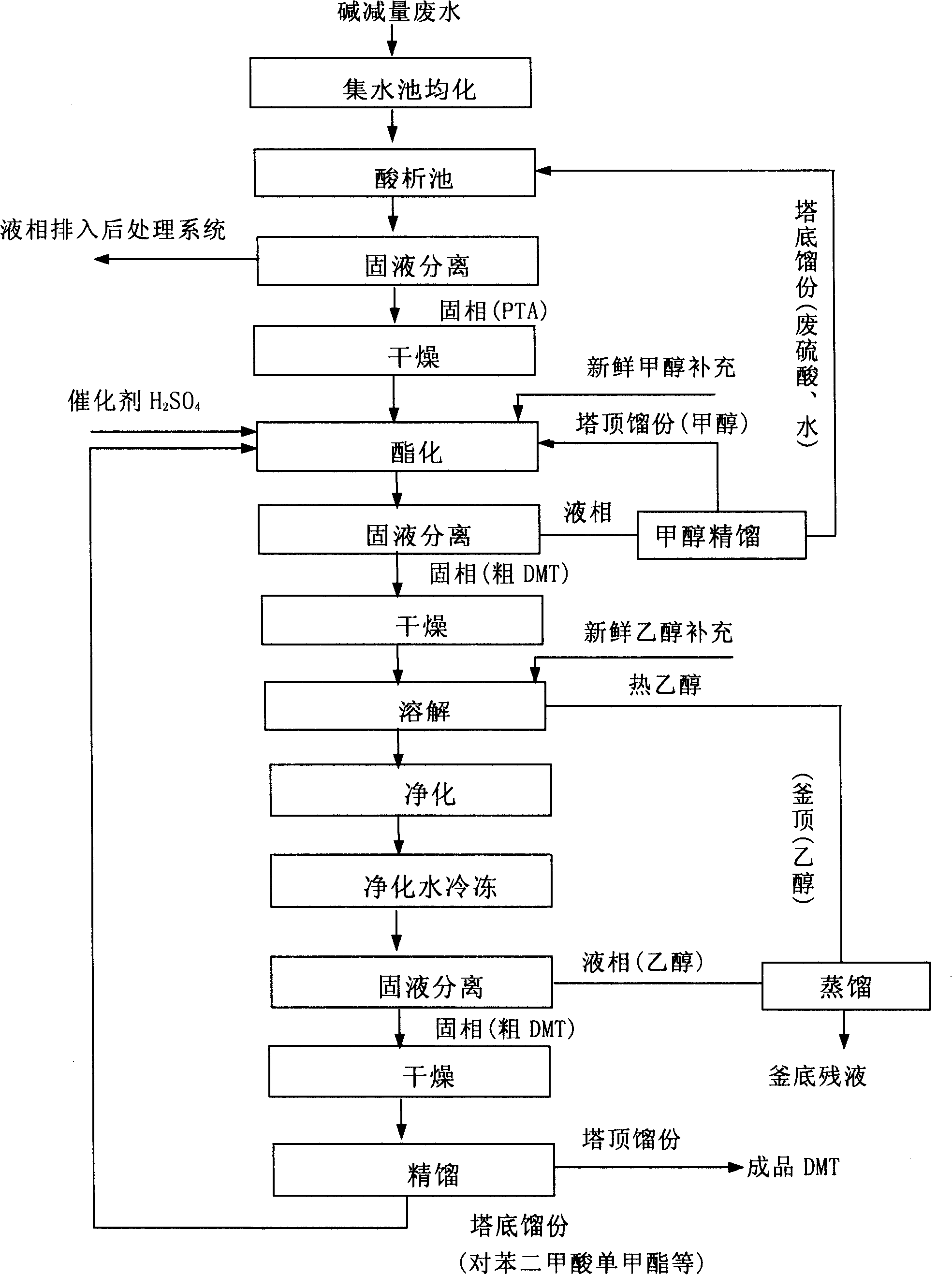

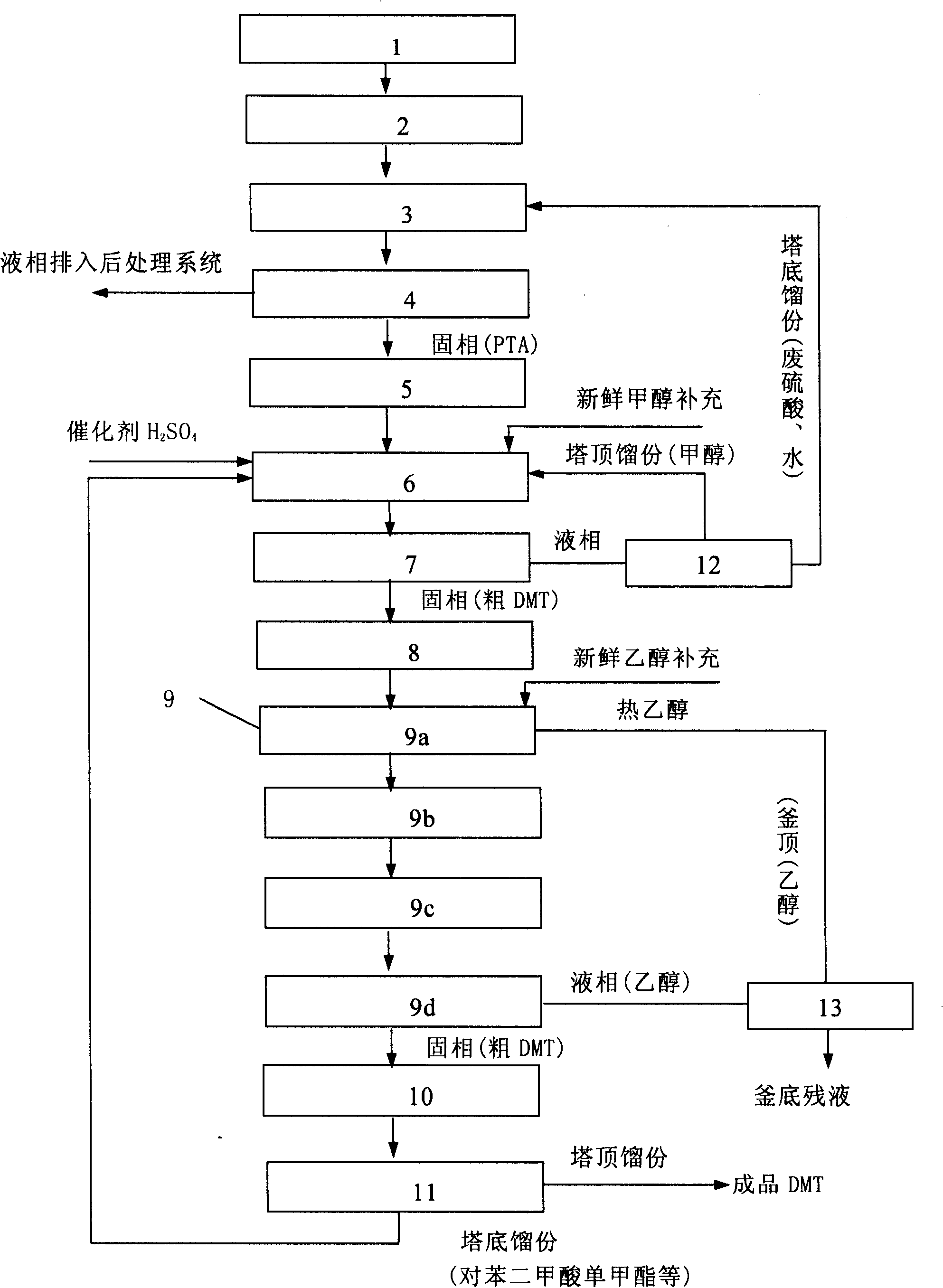

Alkali deweighting wastewater processing method and device

A technology for alkali reduction wastewater and treatment methods, which is applied in textile industry wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., and can solve problems such as inability to be directly and effectively removed, many precipitated impurities, and limited recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Take 0.5m of alkali reduction wastewater from polyester warp knitted fabric 3 , The measured pH is 14, COD cr At 25000mg / L. Sulfuric acid with a concentration of 98% by weight was added to adjust the pH of the wastewater to 7, and the amount of acid added was determined by the acid drop of the filter liquid without terephthalic acid precipitation. Collect the precipitated solid terephthalic acid, weigh 100 g after drying, add 50 ml of 98% sulfuric acid and 500 ml of methanol, and react at 70° C. for 10 hours to obtain DMT crystals. After drying, take 50g crude DMT into 200ml ethanol solution and heat to 60°C. DMT is dissolved to obtain a turbid ethanol mixture. This solution is filtered through activated carbon to obtain a clear solution. The resulting clear solution was frozen to 10°C under ice cooling. At this time, DMT crystals precipitated.

Embodiment 2

[0129] Take the alkali reduction wastewater 0.3m of the artificial silk polyester fabric 3 , The pH value is 12.1. Spent sulfuric acid with a concentration of 31 wt% is added, and the pH drops to 6.5. Collect the precipitated solid terephthalic acid and weigh 200 g after drying. Add 58ml of 98% sulfuric acid and 600ml of methanol. At 110℃, 4kgf / cm 2 Under the conditions, react for 3 hours to obtain DMT crystals. Weigh 50g, add 200ml of analytically pure ethanol, all crystals are dissolved at 50°C, add pottery clay, stir and filter through a ceramic microporous tube to obtain a pure clear liquid, condense to 10°C, and all DMT crystals are precipitated.

Embodiment 3

[0131] Using 200ml of waste sulfuric acid with a concentration of 65% in the above test, the pH14 alkaline reduction wastewater of ponge to obtain 80 grams of terephthalic acid was obtained. After esterification reaction (70℃ normal pressure) for 12 hours, DMT crystals were obtained and dissolved in hot ethanol. After adding barium carbonate and stirring, there will be CO2 bubbles and white barium sulfate precipitation. Then add walnut shell filter material, filter through dense filter cloth, and obtain recrystallization at room temperature of 25°C. After the crystals are dried, the purity of DMT is distilled once to reach 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com