Preparation method of pcb board with prefabricated solder and pcb board

A PCB board and solder technology, which is applied in the field of PCB board preparation, can solve the problems of increasing the technical difficulty of micropowder preparation, the increase of preparation cost, and the complexity of the process, so as to achieve easy personalized circuit design and agile manufacturing, eliminate waste liquid pollution discharge, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

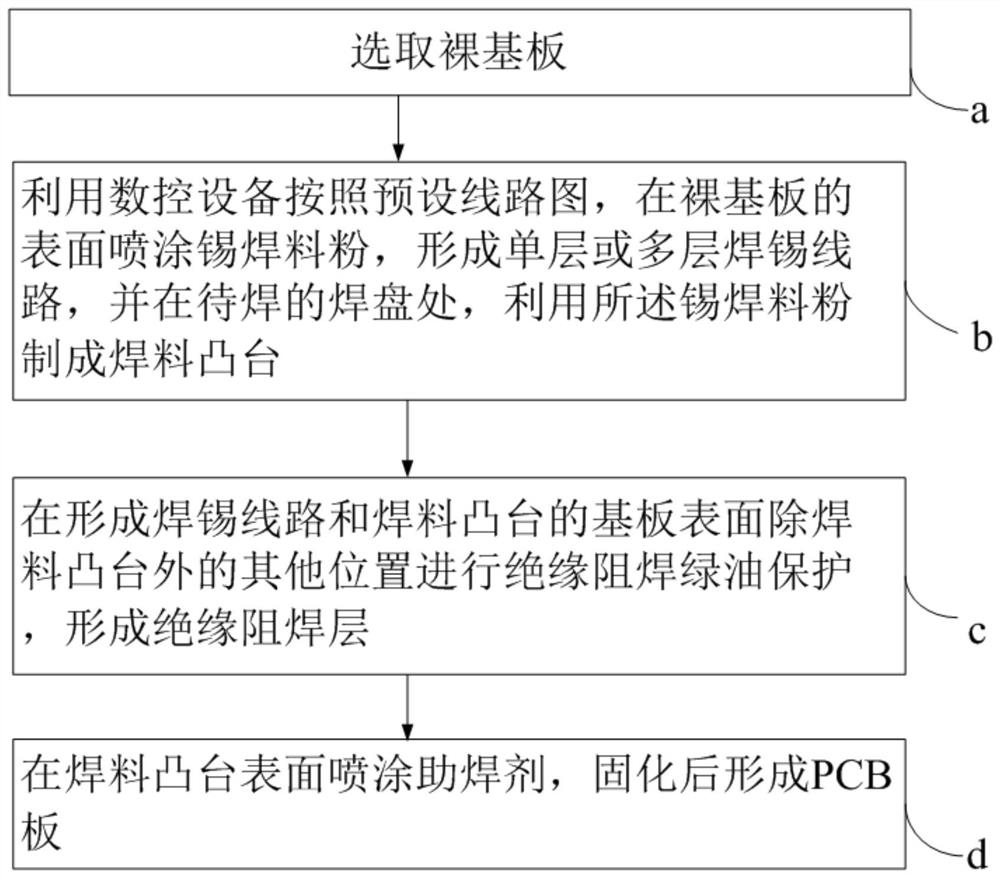

[0023] The preparation method of embodiment 1 single-layer PCB board 1

[0024] First, use FR-4 epoxy resin as the base material to make the PCB core board, bake the core board at 150°C for 4 hours, remove the water vapor in the board, further cure the resin, and eliminate the internal stress of the board. Cut the substrate according to the cutting size of 580mm×470mm, take the middle part of 550mm×440mm as the final product size, and leave a process edge around the substrate to facilitate lamination and alignment in the subsequent production process. Grinding and rounding the substrate to keep the edges and corners of the substrate flat and round, and then use a plate washer to remove resin, dust, impurities, etc. exposed on the surface of the substrate, roughen the surface, and increase adhesion for subsequent processing .

[0025] Secondly, according to the predetermined PCB circuit diagram, through the thermal spraying process, use the numerical control equipment to unifo...

Embodiment 2

[0029] The preparation method of embodiment 2 multilayer PCB board 2

[0030] The same process as in Example 1 is used to prepare six PCB boards with different solder circuit patterns, wherein in this method, the tin solder powder adopts 25-45 μm SnZn9 alloy powder, and after electrostatic spraying, it is necessary to use a miniature impact hammer to solder the solder circuit. Ultrasonic hammering for densification.

[0031] Lay six PCB boards with conductive circuit patterns in sequence according to the design requirements, and through the pre-made target holes, the patterns between the layers can be accurately aligned to avoid misalignment and open circuits that affect the reliability of the product. The PCB boards are bonded and laminated through the prepreg to obtain a six-layer PCB. Finally, use a numerical control spray gun to evenly spray a layer of adjusted flux on the reserved tin solder pad, and seal it up after the flux solidifies. After testing, under the prepara...

Embodiment 3

[0033] The preparation method of the FPC board 3 (flexible circuit board) of embodiment 3 double-sided preset solder

[0034] First, polyimide is used as the base material to manufacture FPC flexible core boards, and the soft boards are pretreated by cutting, cleaning, surface roughening, etc., to remove dust and impurities exposed on the substrate surface, and to increase adhesion for subsequent processing . On the upper and lower surfaces of the processed board core, use the same process steps as in the embodiment to form solder lines, welding bosses and insulating solder resist layers in turn, and then use the same process steps as in Example 1 to weld the bosses. The surface is sprayed with flux, and it can be sealed after the flux solidifies. After testing, under the preparation method, the yield can reach 99%.

[0035]The front and back sides of the FPC board 3 prepared by this method are all provided with single-layer solder lines and solder bosses, the solder bosses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com