Quick response energy storing heat dissipation plate

A fast-response, heat-dissipating plate technology, which is applied in the field of heat-dissipating devices and fast-response energy storage heat-dissipating plates, can solve the problems of spacecraft weight gain, device damage, and reduced reliability of the entire star, achieving good development prospects, high reliability, and Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment, technical solution of the present invention is described in further detail:

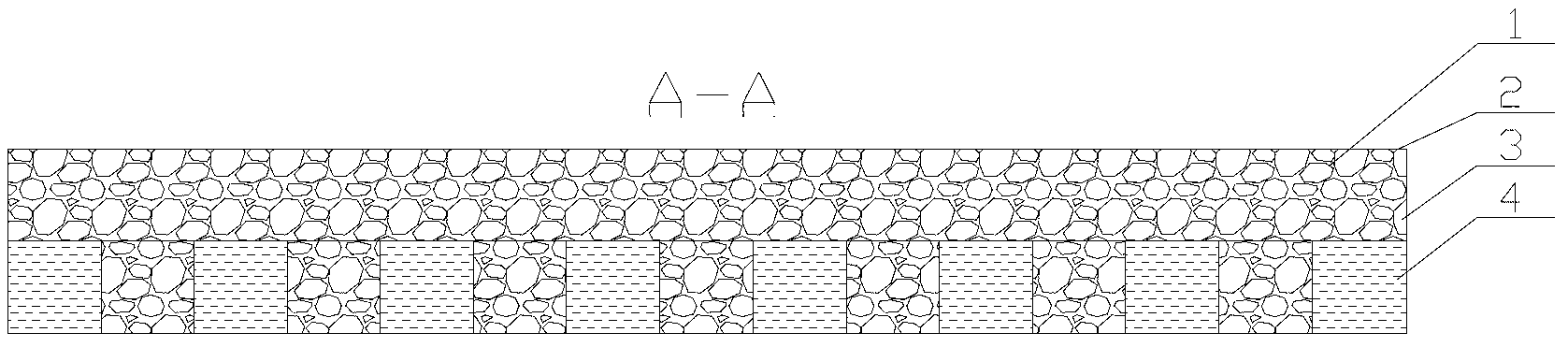

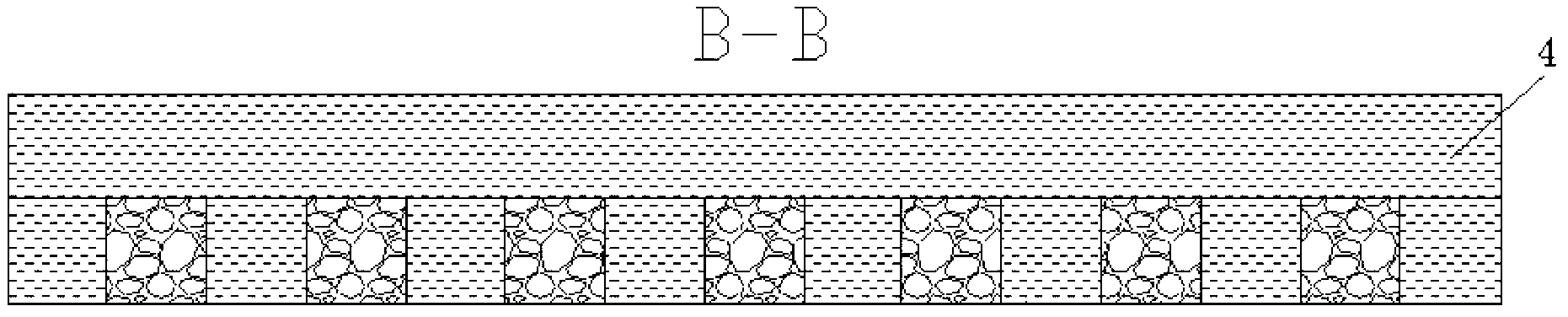

[0033] Such as Figure 1 ~ Figure 3 As shown, the fast-response energy storage and cooling plate provided by the present invention includes a new type of foam material 1 , a radiation plate 2 , a phase change material 3 , and a circulating working medium 4 . The radiant panel 2 mills out a large number of inner cavities with regular shapes and uniform sizes from a thick-walled aluminum plate by a milling machine. The new foam material 1 is filled into part of the cavity of the radiant plate 2 by foaming, and the cavity of the radiant plate 2 that is not filled with the new foam material 1 is filled with ammonia or other circulating working fluid 4 to form a large number of micro heat pipes; The material 3 is filled into the voids of the novel foam material 1 in a liquid state after being heated. After the phase change ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com