Energy storage material of solid - solid phase change in opal / polyurethane type, and preparation method

A phase-change energy storage material, opal technology, applied in the field of opal/polyurethane solid-solid phase-change energy storage materials and its preparation, can solve the problems of short life, volatile, unstable performance of polyols, etc., and achieve low cost , Improve the crystallization performance, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

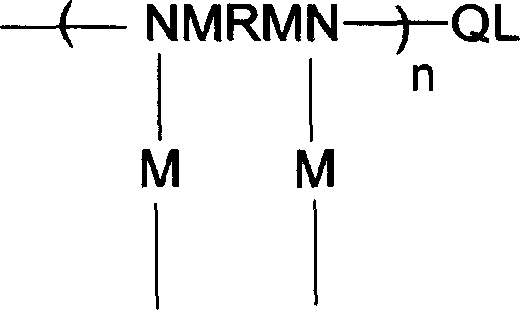

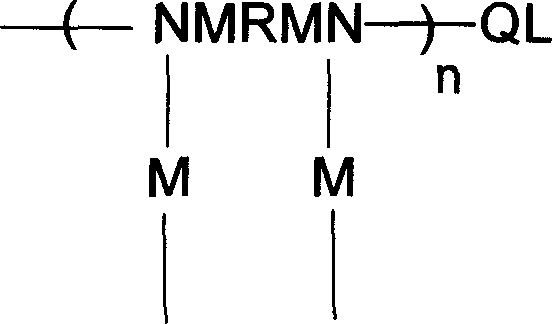

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of polyethylene glycol (M=2000) / TDI prepolymer

[0027] Weigh 0.01mol of TDI and dissolve it in 10ml of acetone solvent, add it to a three-necked flask, add an appropriate amount of catalyst dropwise, stir evenly, add 0.1g of opal micropowder, 2 Add 30 ml of PEG acetone solution containing 0.005 mol molecular weight of 2000 under gas protection, stir for 10 minutes, heat to reflux, and react for 3 hours to obtain an activated sample.

[0028] (2) Preparation of polyethylene glycol (M=2000) / TDI / glycerol / opal solid-solid phase change material

[0029] Weigh 0.01mol of glycerol and dissolve it in 10ml of acetone solvent, add it to a three-necked bottle, add an appropriate amount of catalyst dropwise, stir evenly, wait until the dropwise addition is completed, 2 Heating to reflux under gas protection, and reacting for 3 hours, put the obtained product into a vacuum oven to dry the solvent to obtain a solid-solid phase transition material.

Embodiment 2

[0031] (1) Preparation of polyethylene glycol (M=5000) / TDI prepolymer

[0032] Weigh 0.01mol of TDI and dissolve it in 10ml of acetone solvent, add it to a three-necked flask, add an appropriate amount of catalyst dropwise, stir evenly, add 0.1g of opal micropowder, 2 Add 30 ml of PEG acetone solution containing 0.005 mol molecular weight 5000 under gas protection, stir for 10 minutes, heat to reflux, and react for 3 hours to obtain an activated sample.

[0033] (2) Preparation of polyethylene glycol (M=5000) / TDI / glycerol / opal solid-solid phase change material

[0034] Weigh 0.01mol of glycerol and dissolve it in 10ml of acetone solvent, add it to a three-necked bottle, add an appropriate amount of catalyst dropwise, stir evenly, wait until the dropwise addition is completed, 2 Heating to reflux under gas protection, and reacting for 3 hours, put the obtained product into a vacuum oven to dry the solvent to obtain a solid-solid phase transition material.

Embodiment 3

[0036] (1) Preparation of polyethylene glycol (M=10000) / TDI prepolymer

[0037] Weigh 0.01mol of TDI and dissolve it in 10ml of acetone solvent, add it to a three-necked flask, add an appropriate amount of catalyst dropwise, stir evenly, add 0.1g of opal micropowder, 2 Add 30ml of PEG acetone solution containing 0.005mol molecular weight 10,000 under gas protection, stir for 10 minutes, heat to reflux, and react for 3 hours to obtain an activated sample.

[0038] (2) Preparation of polyethylene glycol (M=10000) / TDI / glycerol / opal solid-solid phase change material

[0039] Weigh 0.01mol of glycerol and dissolve it in 10ml of acetone solvent, add it to a three-necked bottle, add an appropriate amount of catalyst dropwise, stir evenly, wait until the dropwise addition is completed, 2 Heating to reflux under gas protection, and reacting for 3 hours, put the obtained product into a vacuum oven to dry the solvent to obtain a solid-solid phase transition material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com