Method for measuring contact resistance on line

A technology of contact resistance and contact elements, which is applied in the field of monitoring of power transmission and transformation equipment in power systems, and can solve problems such as narrow application range and difficulty in accurate measurement of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

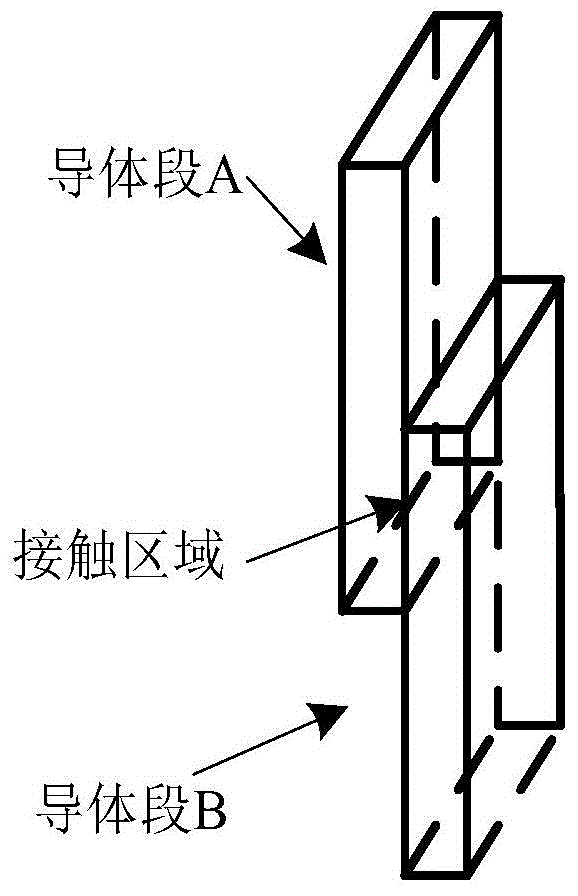

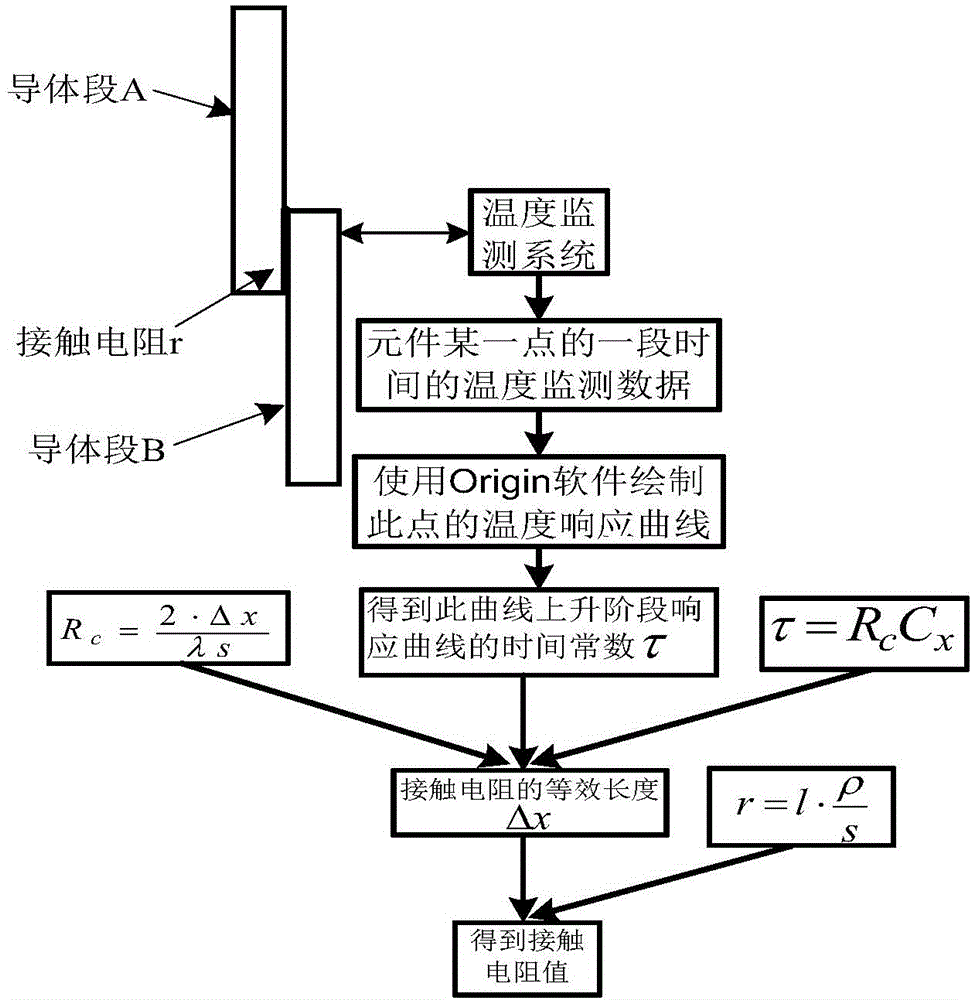

[0025] Step 1. Taking the copper bus bar as an example, the parameters of the relevant materials are shown in Table 1, and assuming that the ambient temperature of the operating condition is 8°C, the heat source energy transmission proportional coefficient of the contact resistance of the heat source area is p=0.5, and the bus bar connection is as follows: figure 1 For the structure shown in , a large amount of temperature data is obtained by collecting temperature values at a distance of 1 cm from the center of the heat source.

[0026] Table 1 Relevant parameters of copper busbar

[0027]

[0028] Step 2. Based on the results of step 1, use the software Origin to analyze the data and draw a curve fitting like Figure 4 Thermal time constant response curve for the center of the heat zone of the copper bus bar.

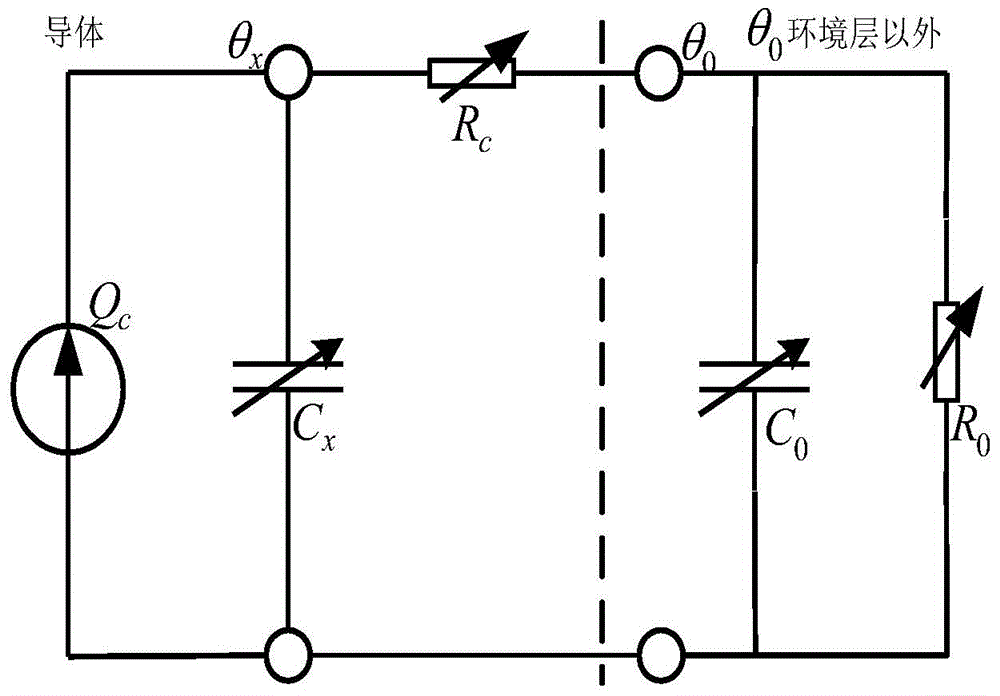

[0029] Step 3. Use the first-order heat path model:

[0030] θ xt = θ ∞ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com