Phase change microspheres, intelligent temperature-adapting fiber and preparation methods thereof

A technology of phase change microspheres and intelligent temperature regulation, which is applied in the field of fibers, can solve the problems that the phase change performance has not been improved, the thermal conductivity of materials cannot be improved, and it is difficult to ensure the effective coating of phase change materials, so as to achieve thermal response and fast Effect of Thermal Response, High Mechanical Properties and Thermal Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

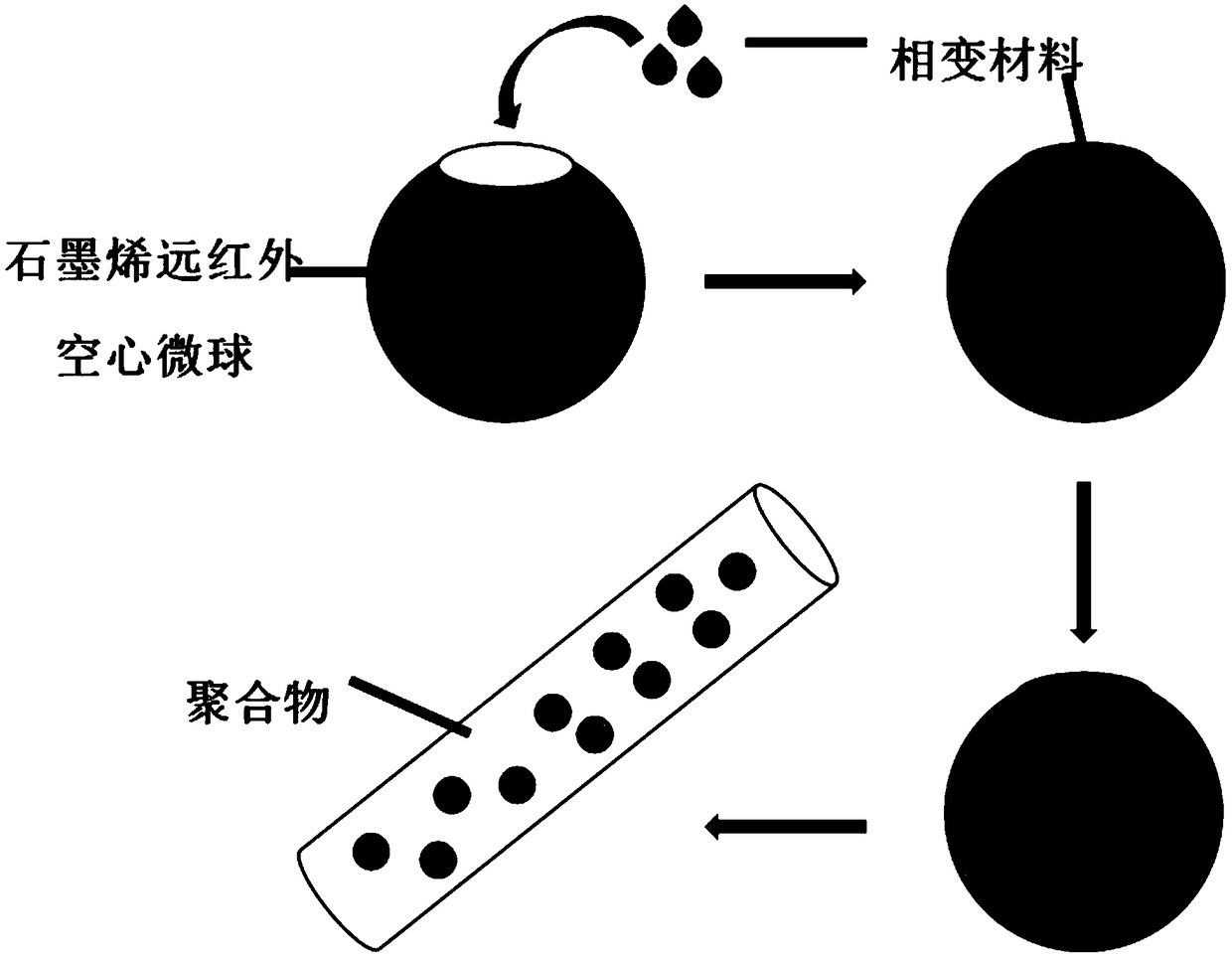

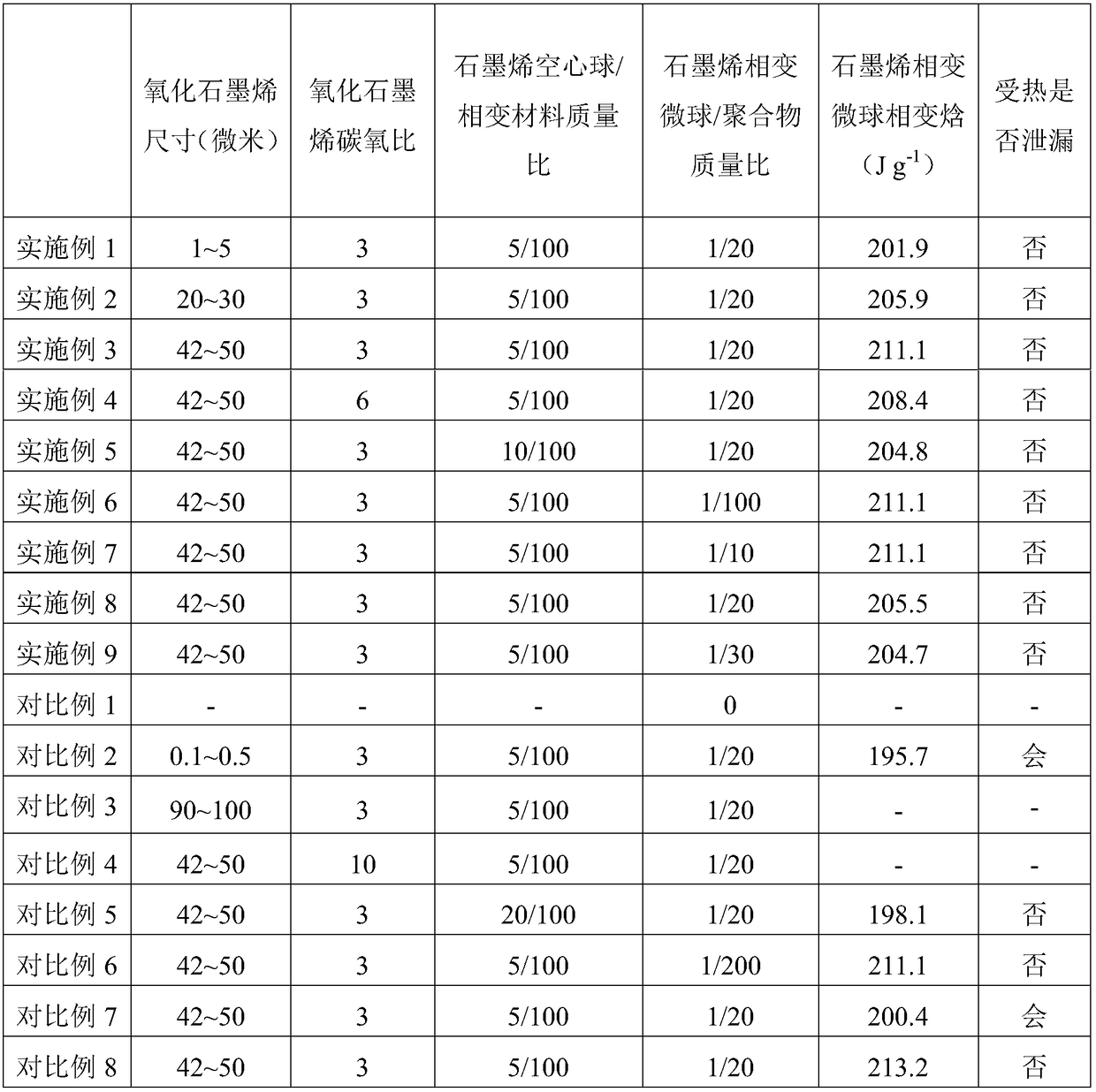

[0031] (1) Add nanometer far-infrared powder to the single-layer graphene oxide dispersion liquid with a size of 1-50 microns and mix evenly. The mass ratio of graphene oxide and nanometer far-infrared powder is 1:1.

[0032] (2) The dispersion liquid obtained in step (1) is dried by atomization drying method to obtain graphene oxide / nano far-infrared powder composite microspheres, the carbon-oxygen ratio of graphene oxide is 3, and the temperature of atomization drying is 130 ℃.

[0033] (3) Put the graphene oxide / nano-far-infrared powder composite microspheres obtained in step (2) in a tube furnace, raise the temperature to 1300°C at 10°C / min, and keep warm for 1h to obtain graphene far-infrared hollow microspheres.

[0034] (4) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene hollow microspheres, heat to 40° C. to melt the eicosane, then fully stir for 30 minutes, leave to stand for vacuum degassing for 1 hour, and then press filter at 50° C. After cooling...

Embodiment 2

[0038] (1) Add nanometer far-infrared powder to the single-layer graphene oxide dispersion liquid with a size of 20-30 microns and mix evenly. The mass ratio of graphene oxide and nanometer far-infrared powder is 1:1.

[0039] (2) The dispersion liquid obtained in step (1) is dried by atomization drying method to obtain graphene oxide / nano far-infrared powder composite microspheres, the carbon-oxygen ratio of graphene oxide is 3, and the temperature of atomization drying is 130 ℃.

[0040] (3) Put the graphene oxide / nano-far-infrared powder composite microspheres obtained in step (2) in a tube furnace, raise the temperature to 1300°C at 10°C / min, and keep it warm for 1h to obtain graphene far-infrared hollow microspheres.

[0041] (4) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene far-infrared hollow microspheres, heat to 40°C to melt the eicosane, then fully stir for 60 minutes, leave to stand for vacuum degassing for 1 hour, and then press at 50°C Filter ...

Embodiment 3

[0045] (1) Add nanometer far-infrared powder to the single-layer graphene oxide dispersion liquid with a size of 42-50 microns and mix evenly. The mass ratio of graphene oxide and nanometer far-infrared powder is 1:1.

[0046] (2) The dispersion liquid obtained in step (1) is dried by atomization drying method to obtain graphene oxide / nano far-infrared powder composite microspheres, the carbon-oxygen ratio of graphene oxide is 3, and the temperature of atomization drying is 130 ℃.

[0047] (3) Put the graphene oxide / nano-far-infrared powder composite microspheres obtained in step (2) in a tube furnace, raise the temperature to 1300°C at 10°C / min, and keep warm for 1h to obtain graphene far-infrared hollow microspheres.

[0048] (4) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene far-infrared hollow microspheres, heat to 40°C to melt the eicosane, then fully stir for 60 minutes, leave to stand for vacuum degassing for 1 hour, and then press at 50°C Filter and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com