Method for integrated preparing of foam metal phase change temperature control assembly

A technology of temperature control components and metal foam, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of short thermal response time, gap between metal foam and packaging container, affecting thermal response rate, etc., and achieve thermal response time Short, improve the thermal response rate, improve the effect of equivalent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

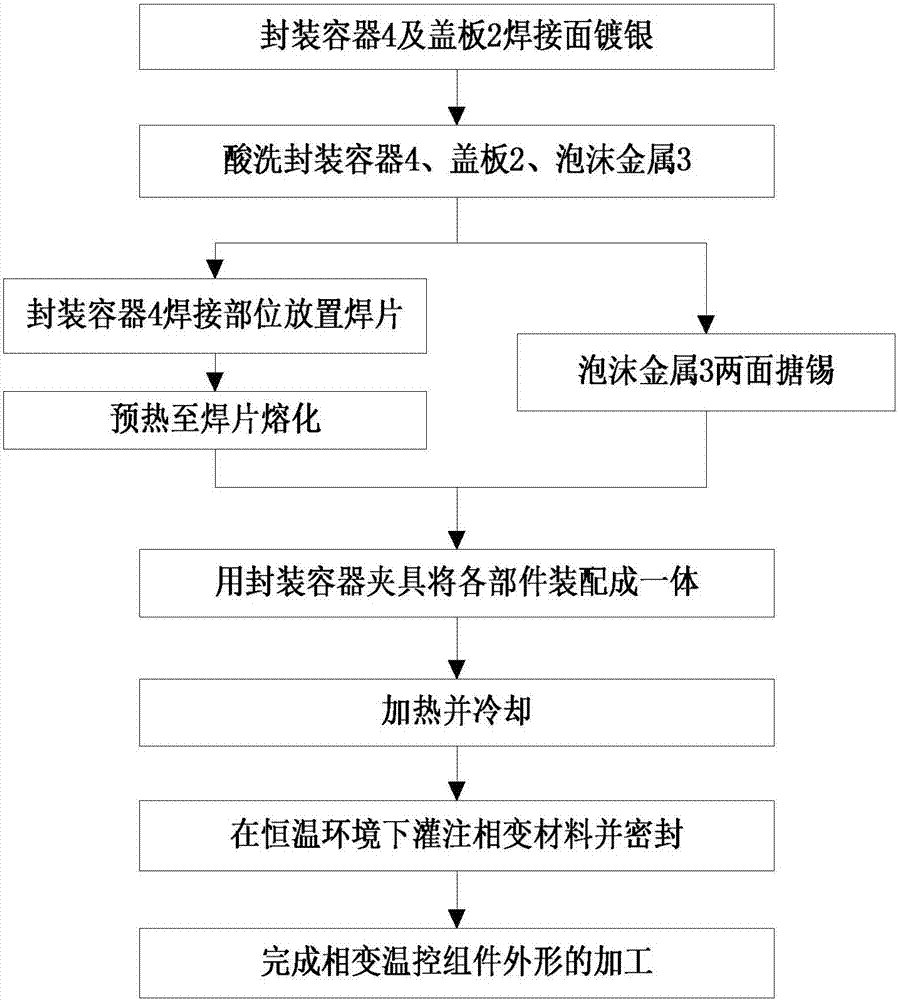

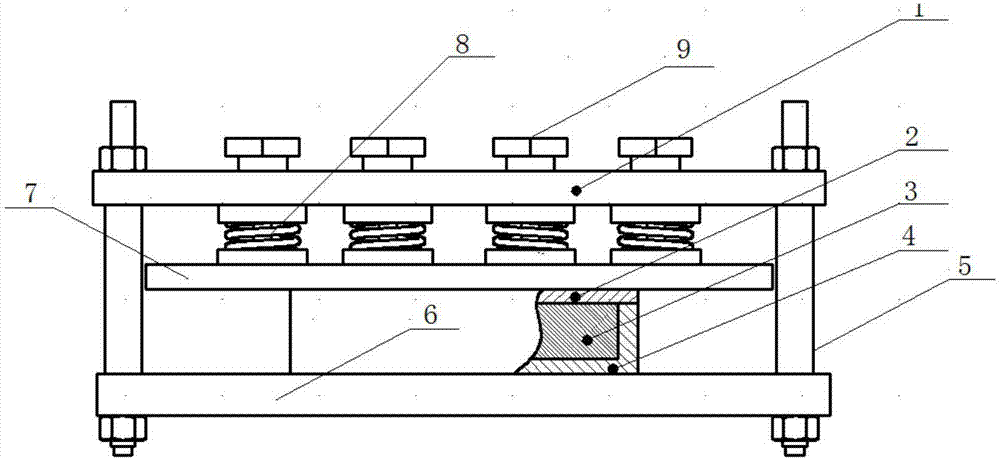

[0035] refer to figure 1 and figure 2 . According to the present invention, first prepare the packaging container fixture according to the external dimensions of the phase change temperature control assembly, pre-process the cavity for welding the foam metal 3 in the packaging container 4, and weld the cavity and the cover plate 2 on the welding surface Pre-plating with silver, and then laying a layer of solder sheet on the welding surface in the cavity of the packaging container 4, preheating the packaging container and the packaging container fixture until the solder sheet is completely melted; compressing the foam metal 3 to the size of the cavity and placing the metal foam 3 on the , the lower contact interface is tinned; the foam metal 3, the packaging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com