Phase-change microsphere, multifunctional phase-change temperature-adjustment fiber, preparation method for phase-change microsphere and preparation method for multifunctional phase-change temperature-adjustment fiber

A technology of phase-change microspheres and temperature-regulating fibers, which is applied in the field of fibers, can solve the problems that the phase-change performance has not been improved, the thermal conductivity of materials cannot be improved, and it is difficult to ensure effective coating of phase-change materials, so as to achieve thermal response and fast Effect of Thermal Response, High Mechanical Properties and Thermal Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

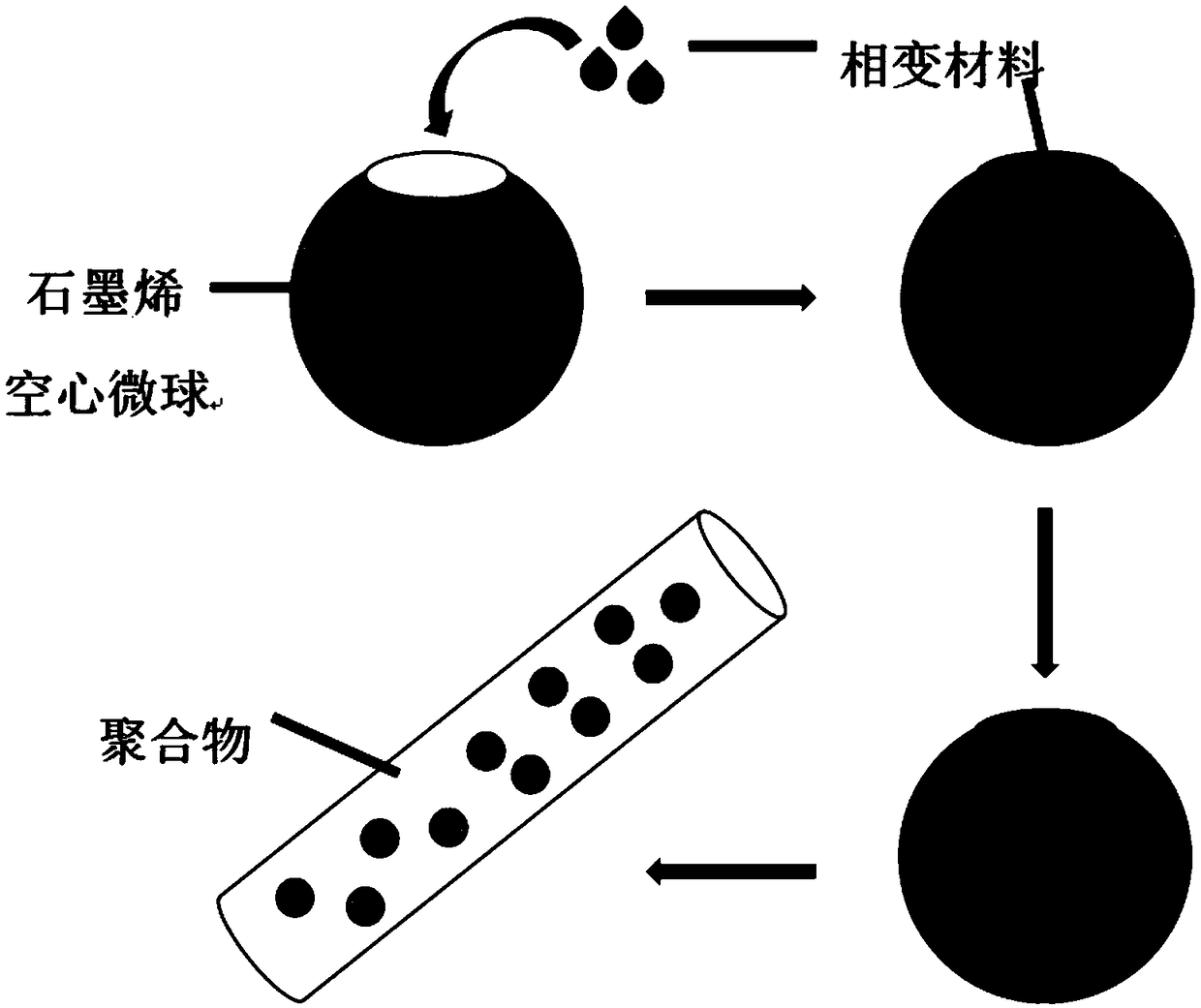

[0029] (1) Drying the single-layer graphene oxide dispersion liquid with a size of 1-5 microns by atomization drying method to obtain graphene oxide microspheres with a carbon-to-oxygen ratio of 3. The atomization drying temperature is 130°C.

[0030] (2) Place the graphene oxide microspheres obtained in step (1) in a tube furnace, raise the temperature to 1300° C. at 10° C. / min, and keep it warm for 1 hour to obtain graphene hollow microspheres.

[0031] (3) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene hollow microspheres, heat to 40° C. to melt the eicosane, then fully stir for 30 minutes, leave to stand for vacuum degassing for 1 hour, and then press filter at 50° C. After cooling, graphene phase change microspheres are obtained.

[0032] (4) Add 1 mass part of the graphene phase-change microspheres obtained in step (3) into 20 mass parts of fiber-grade nylon 6 slices, melt and blend and spin to obtain a multifunctional phase-change temperature-regulat...

Embodiment 2

[0035] (1) Dry the single-layer graphene oxide dispersion liquid with a size of 20-30 microns by atomization drying method to obtain graphene oxide microspheres with a carbon-to-oxygen ratio of 3. The atomization drying temperature is 130°C.

[0036] (2) Place the graphene oxide microspheres obtained in step (1) in a tube furnace, raise the temperature to 1300° C. at 10° C. / min, and keep it warm for 1 hour to obtain graphene hollow microspheres.

[0037] (3) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene hollow microspheres, heat to 40°C to melt the eicosane, then fully stir for 60 minutes, leave to stand for vacuum degassing for 1 hour, and press filter at 50°C, After cooling, graphene phase change microspheres are obtained.

[0038] (4) Add 1 mass part of the graphene phase-change microspheres obtained in step (3) into 20 mass parts of fiber-grade nylon 6 slices, melt and blend and spin to obtain a multifunctional phase-change temperature-regulating fiber...

Embodiment 3

[0041] (1) Dry the single-layer graphene oxide dispersion liquid with a size of 42-50 microns by atomization drying method to obtain graphene oxide microspheres with a carbon-to-oxygen ratio of 3. The atomization drying temperature is 130°C.

[0042] (2) Place the graphene oxide microspheres obtained in step (1) in a tube furnace, raise the temperature to 1300° C. at 10° C. / min, and keep it warm for 1 hour to obtain graphene hollow microspheres.

[0043] (3) Mix 100 parts by mass of eicosane and 5 parts by mass of graphene hollow microspheres, heat to 40°C to melt the eicosane, then fully stir for 20min, leave to stand for vacuum degassing for 1h, and then press filter at 50°C, After cooling, graphene phase change microspheres are obtained.

[0044](4) Add 1 mass part of the graphene phase-change microspheres obtained in step (3) into 20 mass parts of fiber-grade nylon 6 slices, melt and blend and spin to obtain a multifunctional phase-change temperature-regulating fiber.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com