Soldering paste and preparation method thereof, device and welding method

A welding method and solder paste technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of easy oxidation and sintering performance of solder paste, improve thermal cycle stability, simplify process flow, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The embodiment of the present invention also provides a preparation method of the solder paste of any of the above embodiments, comprising the following steps:

[0060] mixing molybdenum carbide, diluent, dispersant and binder to obtain a first mixture;

[0061] Copper powder is mixed with the first mixture to obtain a copper-molybdenum carbide mixture.

[0062] Compared with traditional welding methods, the advantages of the present invention include:

[0063] Simple technological process and low industrial cost;

[0064] The added molybdenum carbide particles, which have a negative Poisson's ratio structure and high hardness, can increase the mechanical strength of the interconnect material;

[0065] The added molybdenum carbide particles can enhance the interface wettability between micro-nano copper particles and chips and substrates, and can enhance the shear strength of interconnect materials;

[0066] The addition of molybdenum carbide changes the thermal expa...

Embodiment 1

[0084] S1: use 4nm molybdenum carbide particles and ethanol, ethylene glycol, polyvinylpyrrolidone, polypropylene alcohol, polyethylene glycol, mix together and then ultrasonically disperse as the first mixture;

[0085] S2: Utilize organic solvents such as formic acid, acetic acid or ethanol to clean the micron copper sheet and 60nm nanometer copper particles, and centrifuge to remove oxides and impurities on the copper surface;

[0086] S3: Add ethanol, ethylene glycol, polyvinylpyrrolidone, polypropylene alcohol, polyethylene glycol to the micronano copper obtained in S2 to obtain a second mixture;

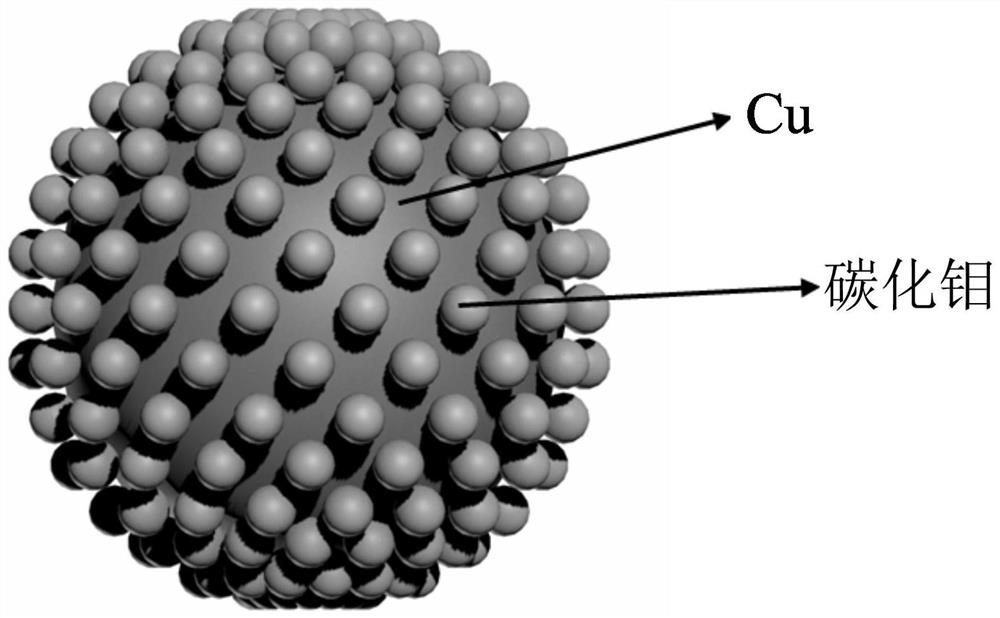

[0087] S4: Add the first mixture described in S1 to the second mixture described in S3 to obtain the second mixture, perform ultrasonic stirring at a speed of 1500 r / min according to the mass ratio of 1:5, and finally prepare by vacuum degassing after centrifugation Micronano Cu-Mo 2 C compound solder paste, the structure is as figure 1 As shown, it will be subsequently used ...

Embodiment 2

[0090] Embodiment 2 is basically the same as Embodiment 1, except that the copper powder only contains nano-copper particles and does not contain micro-copper flakes. That is, micron copper flakes are replaced by nano copper particles of equal mass.

[0091] In a formic acid reducing atmosphere at 180°C, under a pressure of 2 MPa, pre-sintered for 10 seconds, and at 300°C, under a pressure of 10 MPa, for a second sintering of 15 minutes, the shear strength of the obtained sintered body was 55 MPa, and the thermal conductivity was 240 W / mK. Sintering - After a second sintering cycle, the shear strength decreased by 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com