Phase-change thermal storage calcium silicate board and raw materials, preparation method and application thereof

A calcium silicate board, phase change heat storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, lamination, etc., can solve the problems of unreasonable phase change temperature, low heat conduction rate, complicated preparation process, etc., to achieve Good thermal cycle stability, high heat transfer rate, and fast heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

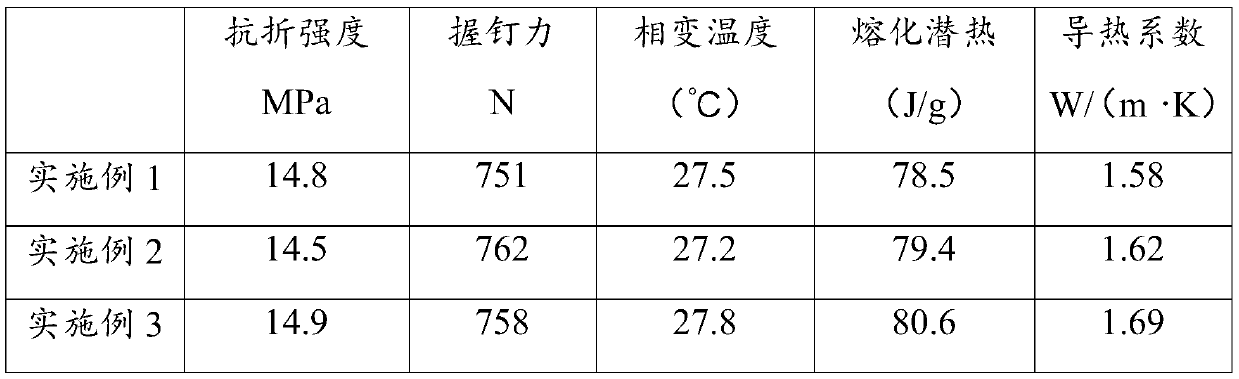

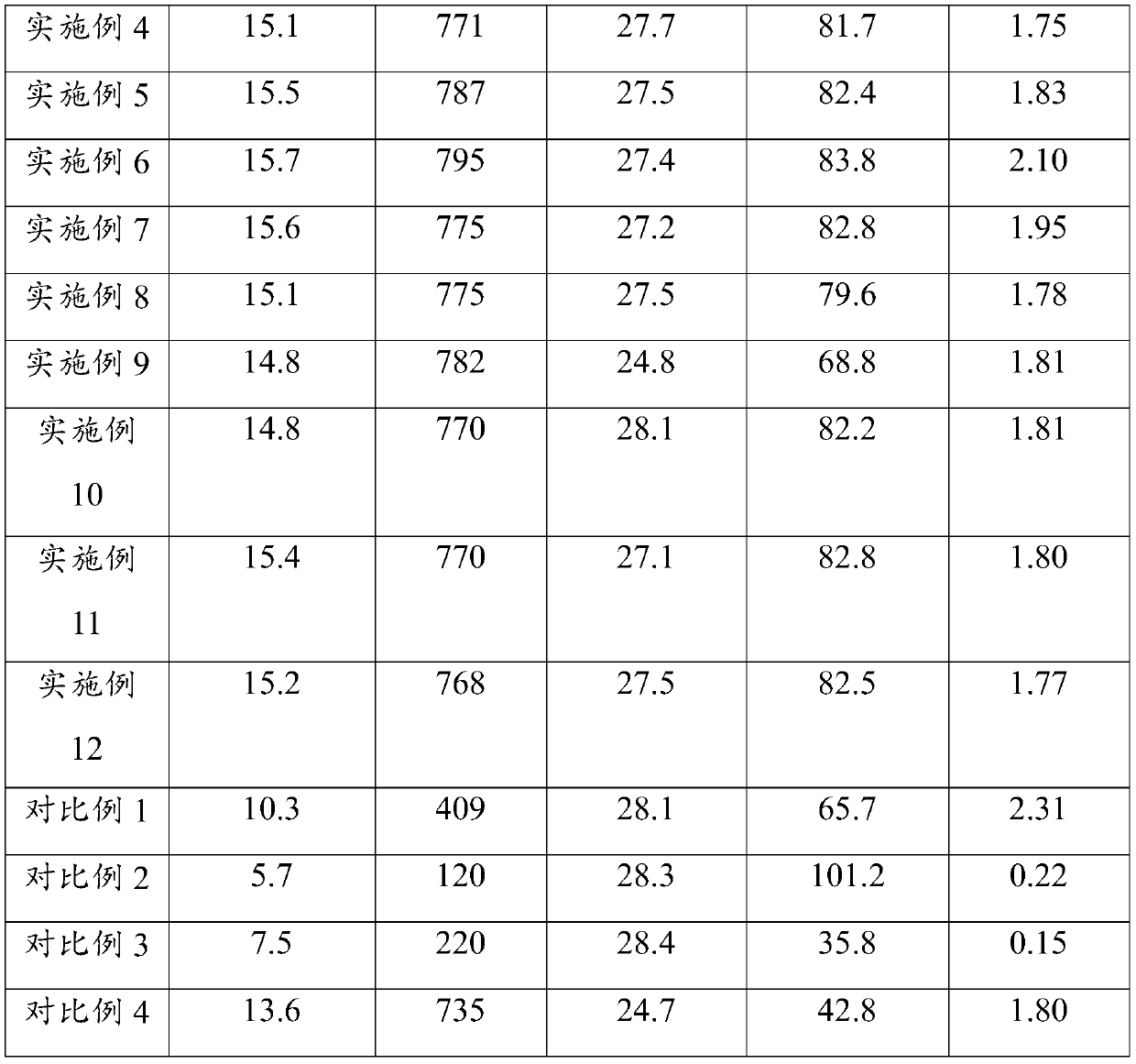

Examples

preparation example Construction

[0065] The preparation method of the phase change heat storage calcium silicate board is to bond the middle layer and the surface layer with an adhesive to obtain a formed board, and the formed board is sequentially subjected to autoclave curing, drying and cutting to obtain a phase change heat storage calcium silicate board . The adhesive adheres the middle layer and the surface layer well to form a whole, the preparation process is simple, the cost is low, and the performance of the prepared phase-change heat storage calcium silicate board is stable.

[0066] In a preferred embodiment, the middle layer includes 8-18 unit layers, and the unit layers are bonded by an adhesive.

[0067] In a preferred embodiment, the binder includes at least one of polyvinyl alcohol, polyethylene glycol or polyethylene oxide. The adhesive realizes a good fit between the surface layer and the middle layer without affecting the heat transfer. The adhesive can be polyvinyl alcohol, polyethylene g...

Embodiment 1

[0074] A raw material for a phase-change heat storage calcium silicate board, in parts by weight, comprising:

[0075] Component A includes: 20 parts of diatomite, 35 parts of slaked lime, 30 parts of paraffin (liquid paraffin: 52# solid paraffin=1:1), 5 parts of graphene oxide, 5 parts of attapulgite, 1 part of wood fiber and 3 parts Parts methyl hydroxyethyl cellulose;

[0076] Component B includes: 30 parts of diatomaceous earth, 40 parts of slaked lime, 10 parts of attapulgite, 10 parts of wood fiber and 3 parts of methyl hydroxyethyl cellulose.

Embodiment 2

[0078] A raw material for a phase-change heat storage calcium silicate board, in parts by weight, comprising:

[0079] Component A includes: 35 parts of diatomite, 20 parts of slaked lime, 45 parts of paraffin (liquid paraffin: 52# solid paraffin=1:1), 1 part of graphene oxide, 15 parts of attapulgite, 5 parts of wood fiber and 1 Parts methyl hydroxyethyl cellulose;

[0080] Component B includes: 45 parts of diatomaceous earth, 30 parts of slaked lime, 15 parts of attapulgite, 5 parts and 1 part of methyl hydroxyethyl cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com