preparation method of composite anode by one-dimensional nano fibrous lanthanum strontium titanate (LST) anode material

A nanofiber, anode material technology, applied in fuel cells, battery electrodes, solid electrolyte fuel cells, etc., can solve problems such as carbon deposition anode materials, achieve high electron conductivity, improve anode thermal cycle stability, and good sulfur resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

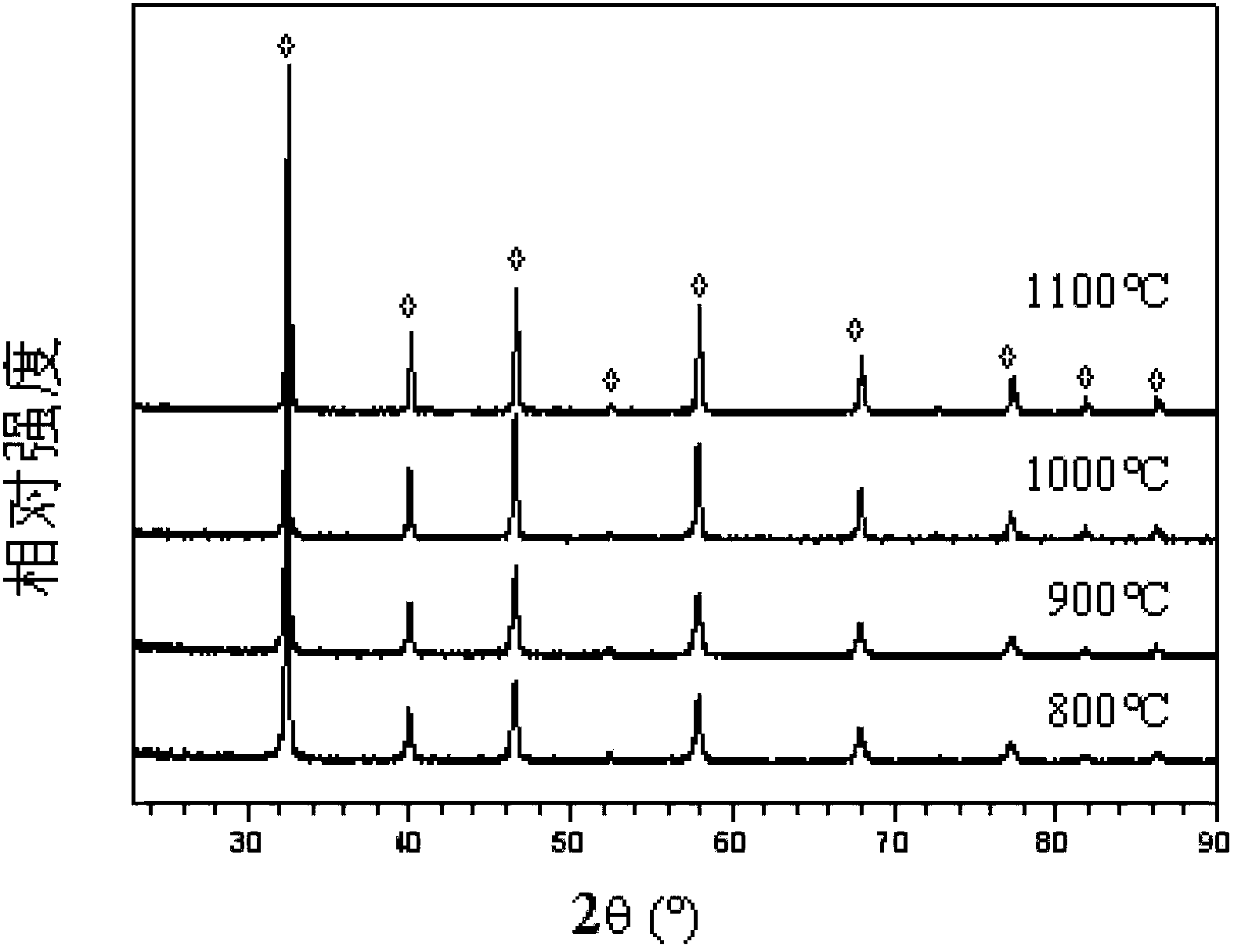

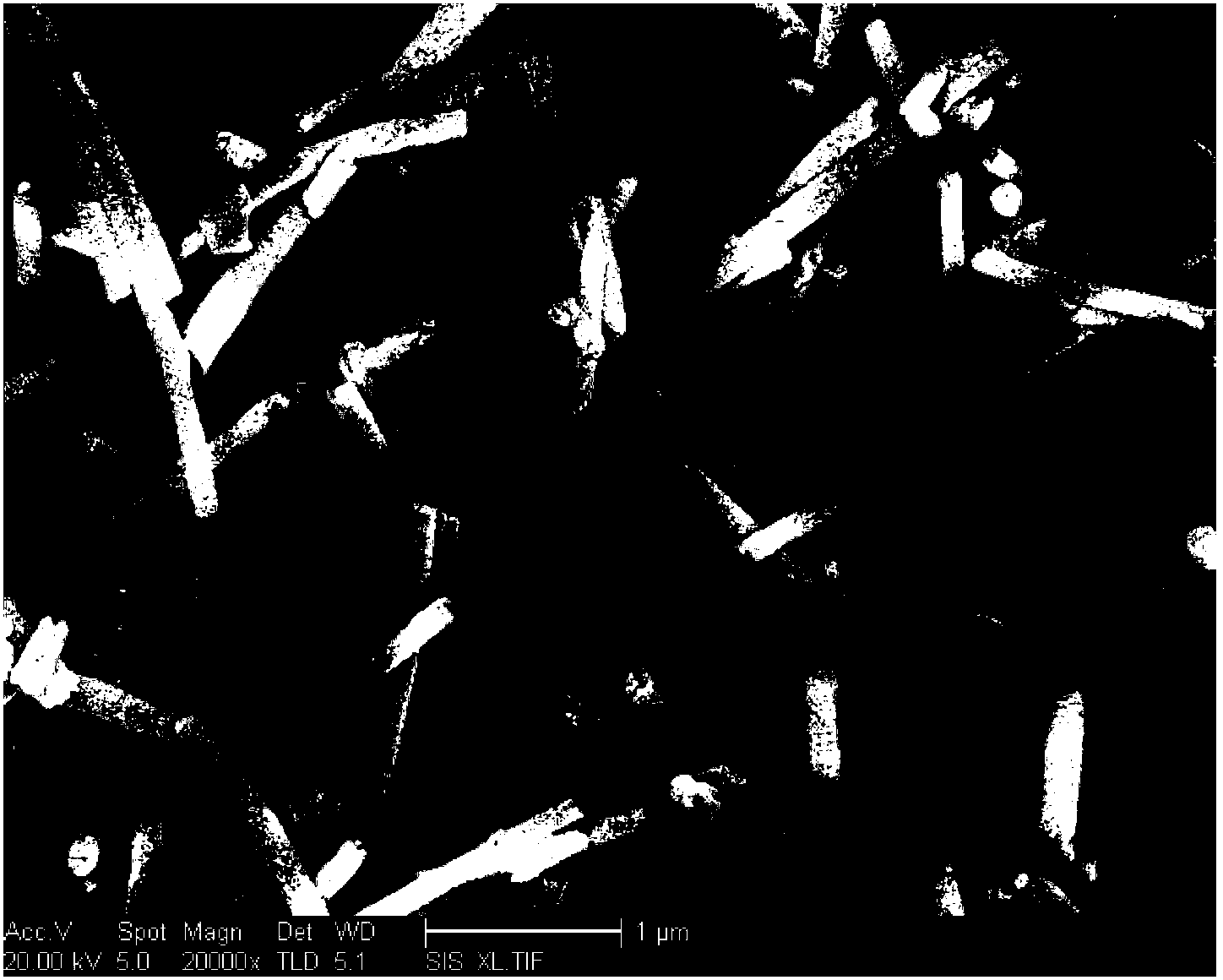

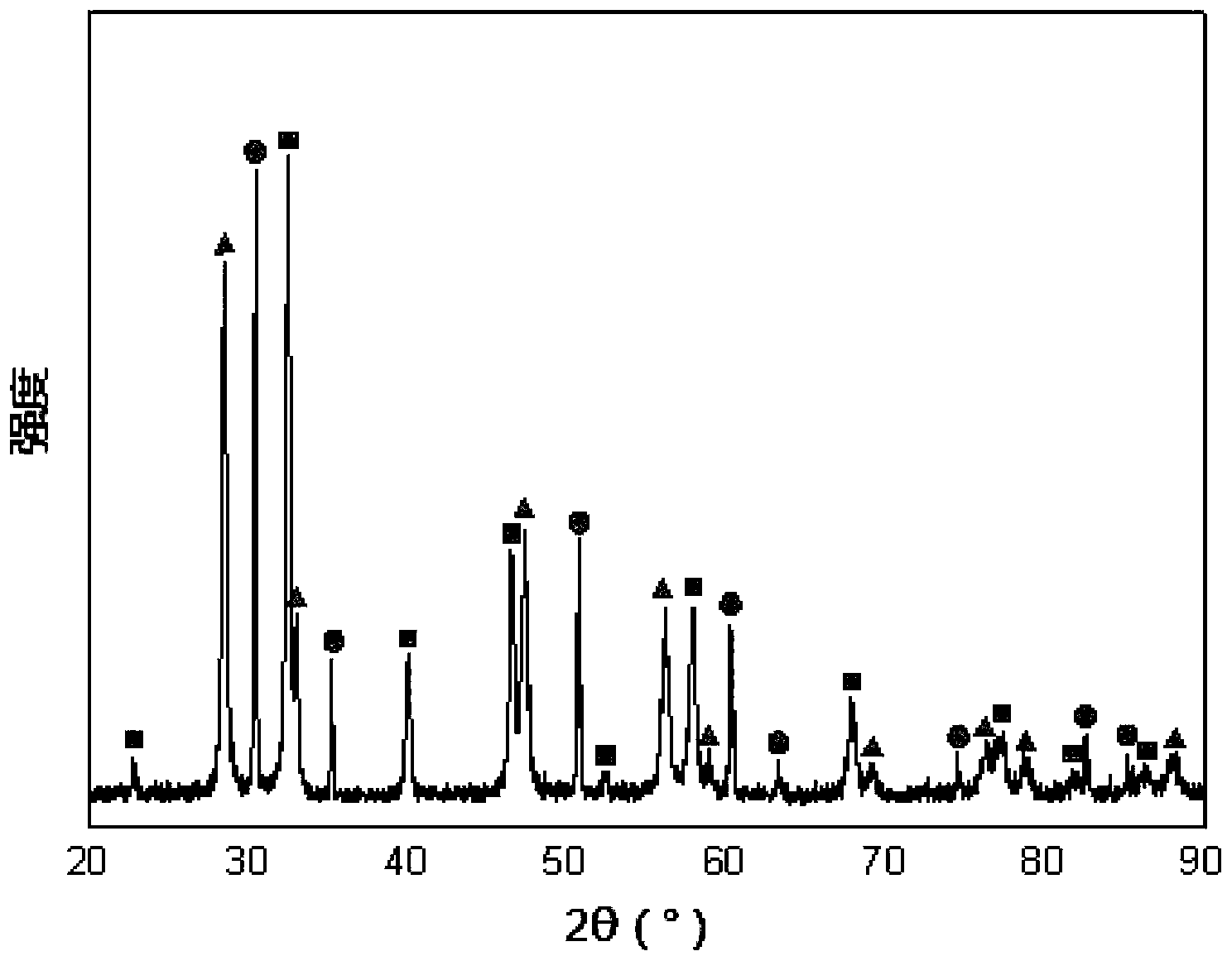

[0029] Specific embodiment one: the chemical formula of the one-dimensional nanofibrous LST anode material of the present embodiment is La x Sr 1-x TiO 3 , wherein 0≤x≤0.4, the structure of the one-dimensional nanofibrous anode material is one-dimensional nanofiber.

specific Embodiment approach 2

[0030] Specific embodiment two: the preparation method of the one-dimensional nanofibrous LST anode material of the present embodiment is as follows:

[0031] 1. Preparation of electrospinning precursor solution: according to the chemical formula La x Sr 1-x TiO 3 , 0≤x≤0.4, weigh lanthanum nitrate, strontium nitrate and tetrabutyl titanate respectively according to the molar ratio of La element, Sr element and Ti element as x:1-x:1, and then add lanthanum nitrate and strontium nitrate Add it into N,N-dimethylformamide, stir magnetically at room temperature until the lanthanum nitrate and strontium nitrate are completely dissolved, then add polyvinylpyrrolidone and stir for 6-8 hours to obtain a mixed solution, add concentrated nitric acid to adjust the pH value of the mixed solution to 4-6, then add tetrabutyl titanate, continue to stir until the mixed solution becomes transparent, and obtain the electrospinning precursor solution;

[0032] The total mass concentration of ...

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 2 in that: the total mass concentration of samarium nitrate, strontium nitrate and tetrabutyl titanate in the electrospinning precursor solution in step 1 is 8-25%. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com