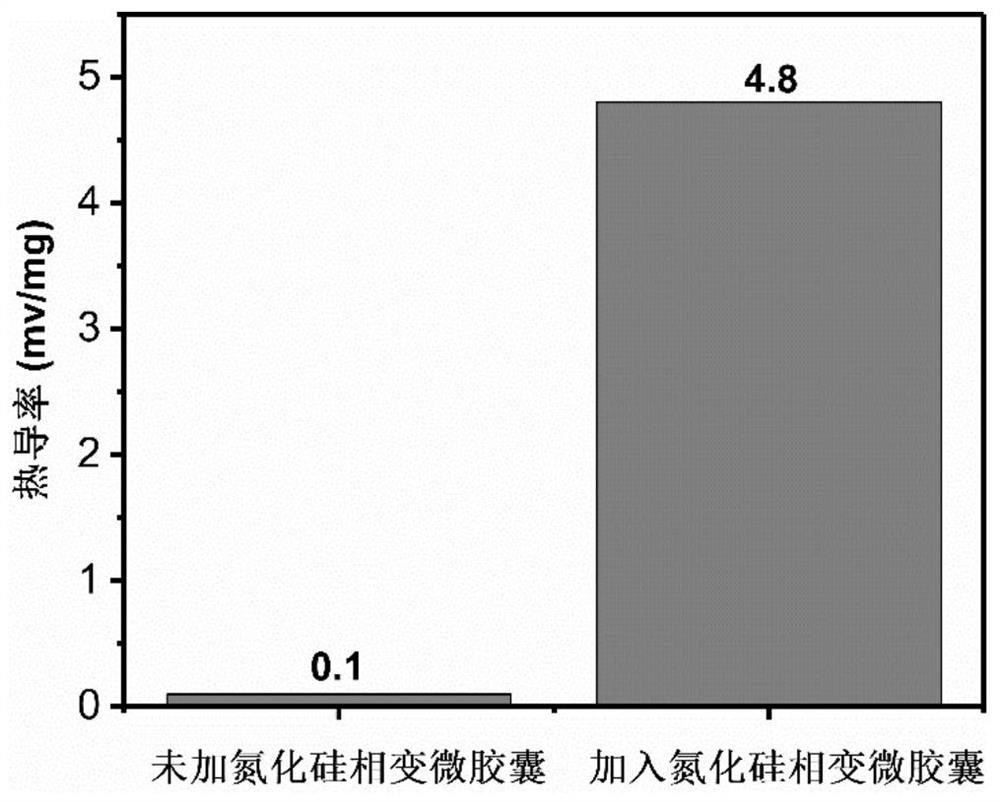

Organic phase-change microcapsule with high coating rate, high thermal conductivity and high thermal cycling stability, and preparation method thereof

A technology with cycle stability and high thermal conductivity, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of low coating rate, poor thermal performance, and small latent heat, etc., and achieve simple ingredients and raw materials Ease of purchase and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

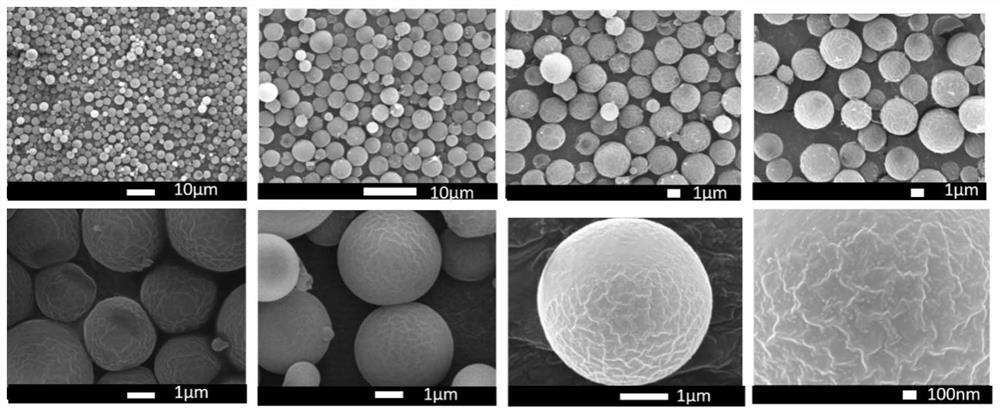

[0044] A preparation method of phase-change microcapsules with high coating rate, high thermal conductivity and high thermal cycle stability, comprising the following steps:

[0045] (1) In a 65°C oil bath, add 10.00 g of dispersant and 100 mL of water into a glass, and stir at a stirring speed of 900 rpm until completely dissolved.

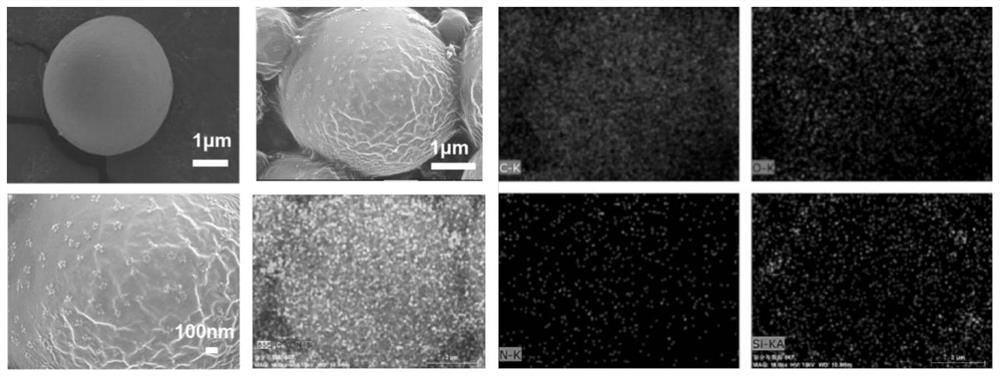

[0046] (2) Weigh 2g of vacuum-dried silicon nitride, disperse it in 300mL of ethyl acetate under ultrasonic conditions, take 0.67g of KH-570 and add it to the ethyl acetate solution system, and the mixed solution is refluxed at 75°C for 3.5h, and the reaction is over Afterwards, the modified nanoparticles are subjected to centrifugation, washing and vacuum drying.

[0047] (3) Accurately weigh 9.33g methyl methacrylate, 4.00gPETRA (pentaerythritol tetraacrylate-crosslinking agent), 0.26g (dilauroyl peroxide) initiator, modified silicon nitride 0.83g and join in In the beaker, the initiator was fully dissolved by ultrasound, and then C was added ...

Embodiment 2

[0055] A preparation method of phase-change microcapsules with high coating rate, high thermal conductivity and high thermal cycle stability, comprising the following steps:

[0056] (1) In a 65°C oil bath, add 8.00 g of dispersant and 100 mL of water into a glass cup, and stir at a stirring speed of 900 rpm until completely dissolved.

[0057] (2) Weigh 2g of vacuum-dried silicon nitride and fully disperse it in 300mL of ethyl acetate under ultrasonic conditions for 5min. Take 0.67g of KH-570 and add it to the ethyl acetate solution system, and the mixed solution is refluxed at 75°C for reaction After 3.5 hours, after the reaction, the modified nanoparticles were centrifuged, washed, and vacuum-dried.

[0058] (3) Accurately weigh 9.33g methyl methacrylate, 3.80gPETRA (pentaerythritol tetraacrylate-crosslinking agent), 0.20g (dilauroyl peroxide) initiator, modified silicon nitride 0.75g and join in In the beaker, the initiator was fully dissolved by ultrasound, and then C wa...

Embodiment 3

[0063] In the present embodiment, a preparation method of phase-change microcapsules with high coating rate, high thermal conductivity and high thermal cycle stability comprises the following steps:

[0064] (1) In a 65°C oil bath, add 12.00g of dispersant and 100mL of water into a glass, and stir at a stirring speed of 900rpm until completely dissolved.

[0065] (2) Weigh 2g of vacuum-dried silicon nitride, disperse it in 300mL of ethyl acetate under ultrasonic conditions, take 0.67g of KH-570 and add it to the ethyl acetate solution system, and the mixed solution is refluxed at 75°C for 3.5h, and the reaction is over Afterwards, the modified nanoparticles are subjected to centrifugation, washing and vacuum drying.

[0066] (3) Accurately weigh 9.33g methyl methacrylate, 4.50gPETRA (pentaerythritol tetraacrylate-crosslinking agent), 0.28g (dilauroyl peroxide) initiator, silicon nitride 0.85g after modification join in In the beaker, the initiator was fully dissolved by ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com