Phase-change high-thermal-conductivity interface material and preparation method thereof

An interface material and high thermal conductivity technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor thermal stability and achieve the effects of reducing contact thermal resistance, good repeatability, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

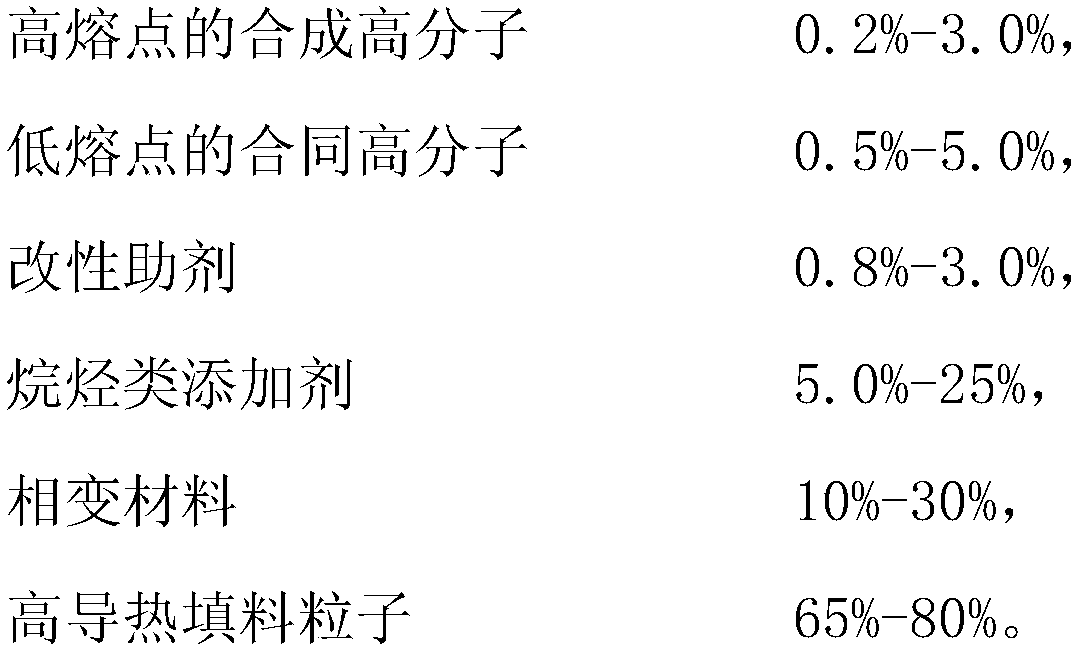

[0031] The mass percent of each raw material is:

[0032]

[0033] 1) Add synthetic polymers with high melting point and alkane additives into the reaction kettle, stir at 160°C for 1 hour, then add synthetic polymers with low melting point, cool down to 120°C and stir for 30 minutes, then add phase change materials and modification additives , after stirring at 120°C for 1 hour, add high thermal conductivity filler particles treated by coupling agent surface, cool down to 90-100°C and stir in vacuum for 40 minutes, defoaming;

[0034] 2) After the product obtained in step 1) is melted on the overheated platform, the upper and lower layers are covered with a protective film, and rolled by a calender to obtain a phase-change high thermal conductivity interface material with a thickness of 0.15 mm.

Embodiment 2

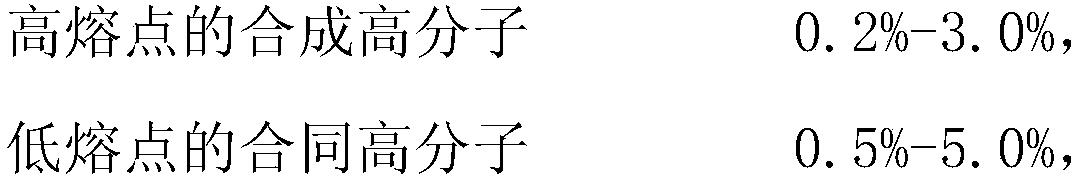

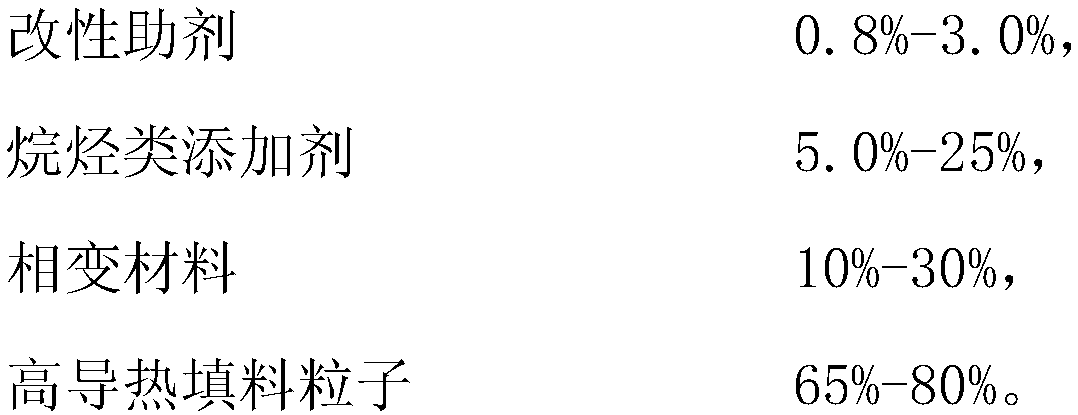

[0036] The mass percent of each raw material is:

[0037]

[0038] 1) Add synthetic polymers with high melting point and alkane additives into the reaction kettle, stir at 160°C for 1 hour, then add synthetic polymers with low melting point, cool down to 120°C and stir for 30 minutes, then add phase change materials and modification additives , after stirring at 120°C for 1 hour, add high thermal conductivity filler particles treated by coupling agent surface, cool down to 90-100°C and stir in vacuum for 40 minutes, defoaming;

[0039] 2) After the product obtained in step 1) is melted on the overheated platform, the upper and lower layers are covered with a protective film, and rolled by a calender to obtain a phase-change high thermal conductivity interface material with a thickness of 0.25 mm.

[0040] The performance of the phase change high thermal conductivity interface material prepared in Example 1-2 is as follows:

[0041]

[0042]

[0043] It can be conclud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com