NiMnGaCu high temperature shape-memory alloy and manufacturing method thereof

A technology of memory alloy and high temperature, which is applied in the field of shape memory alloy, can solve the problems of complex preparation process and high cost, and achieve the effects of low preparation cost, high martensitic transformation temperature and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method and specific steps of the nickel-cobalt-manganese-tin high-temperature shape memory alloy of the present invention are as follows:

[0019] (1) According to Ni 43 co 7 mn 50-X sn X The atomic percentage weighs nickel (Ni) with a purity of 99.9%, cobalt (Co) with a purity of 99.9%, manganese (Mn) with a purity of 99.9% and tin (Sn) with a purity of 99.9%, where X=7~ 10;

[0020] (2) Put the nickel (Ni), cobalt (Co), manganese (Mn) and tin (Sn) raw materials weighed in the first step into a non-consumable vacuum electric arc furnace, and draw a vacuum so that the vacuum degree of the back reaches 2 ×10 -2 ~5×10 -3 Pa, and then filled with high-purity argon to 500Pa, using a high-temperature arc to melt the raw material into a NiCoMnSn button-shaped ingot;

[0021] (3) A rod-shaped ingot with a diameter of 10 mm was prepared by using a vacuum suction casting device to obtain a nickel-cobalt-manganese-tin high-temperature shape memory alloy.

...

Embodiment 1

[0024] Embodiment 1: prepare Ni 43 co 7 mn 41 sn 9 alloy

[0025] (1) According to Ni 43 co 7 mn 41 sn 9 The atomic percent is nickel (Ni) with a purity of 99.9%, cobalt (Co) with a purity of 99.9%, manganese (Mn) with a purity of 99.9% and tin (Sn) with a purity of 99.9%;

[0026] (2) Put the nickel (Ni), cobalt (Co), manganese (Mn) and tin (Sn) raw materials weighed in the first step into a non-consumable vacuum electric arc furnace, and draw a vacuum so that the vacuum degree of the back reaches 2 ×10 -2 ~5×10 -3 Pa, then filled with high-purity argon to 500Pa, using high-temperature arc to smelt the raw material into Ni 43 co 7 mn 41 sn 9 button-shaped ingot;

[0027] (3) Prepare a rod-shaped ingot with a diameter of 10mm by using a vacuum suction casting device to obtain Ni 43 co 7 mn 41 sn 9 High temperature shape memory alloys.

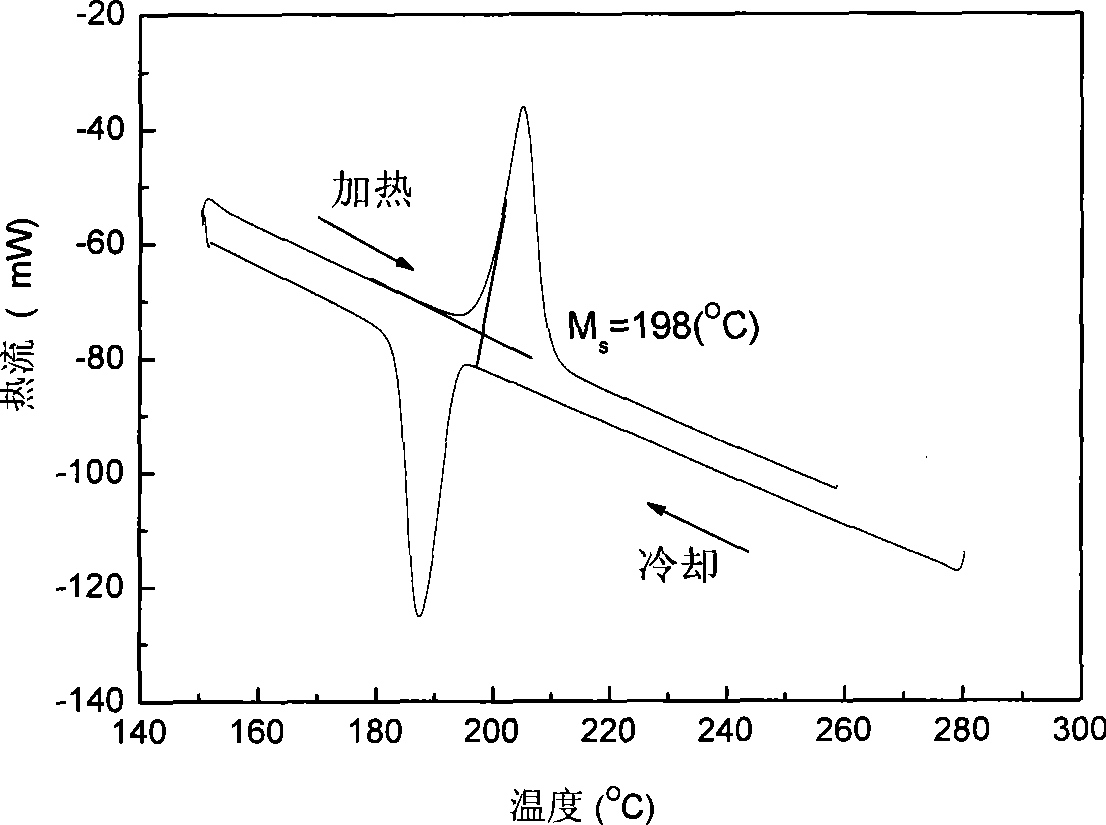

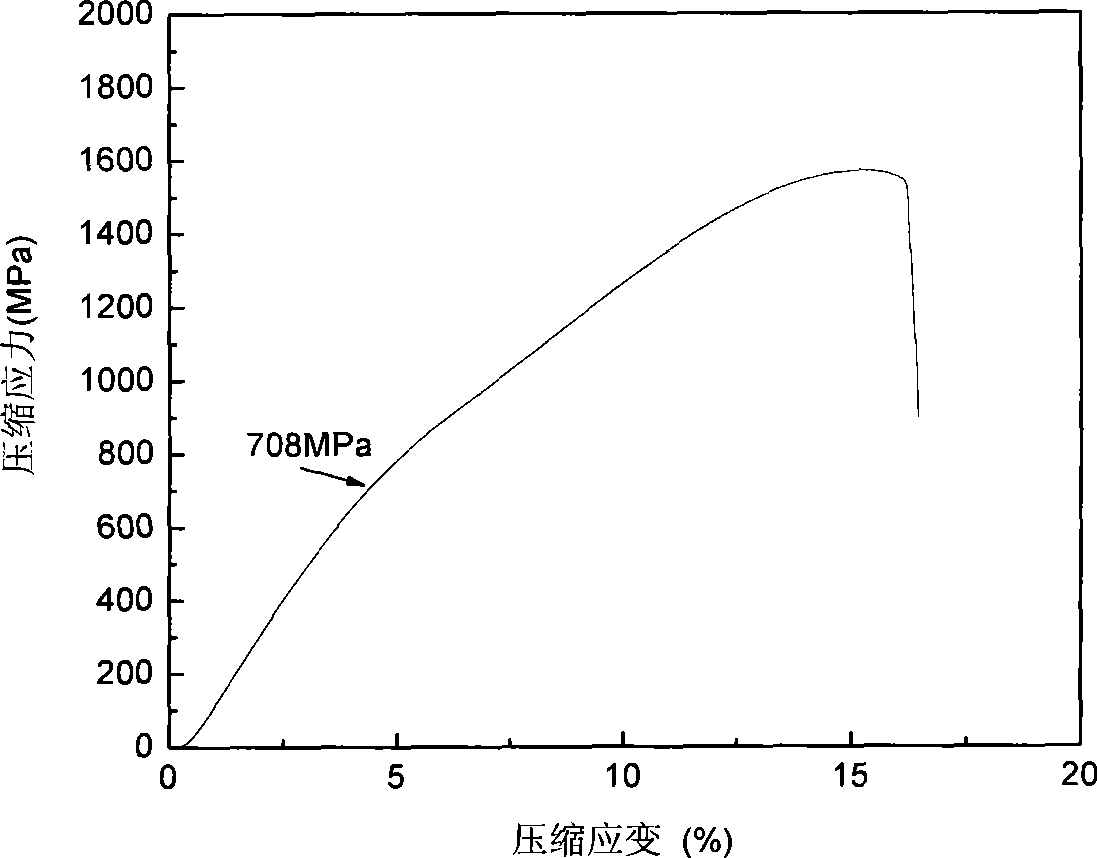

[0028] Using the electric spark cutting method, cut a cuboid with a size of 2×2×3 from the nickel-cobalt-manganese-tin high...

Embodiment 2

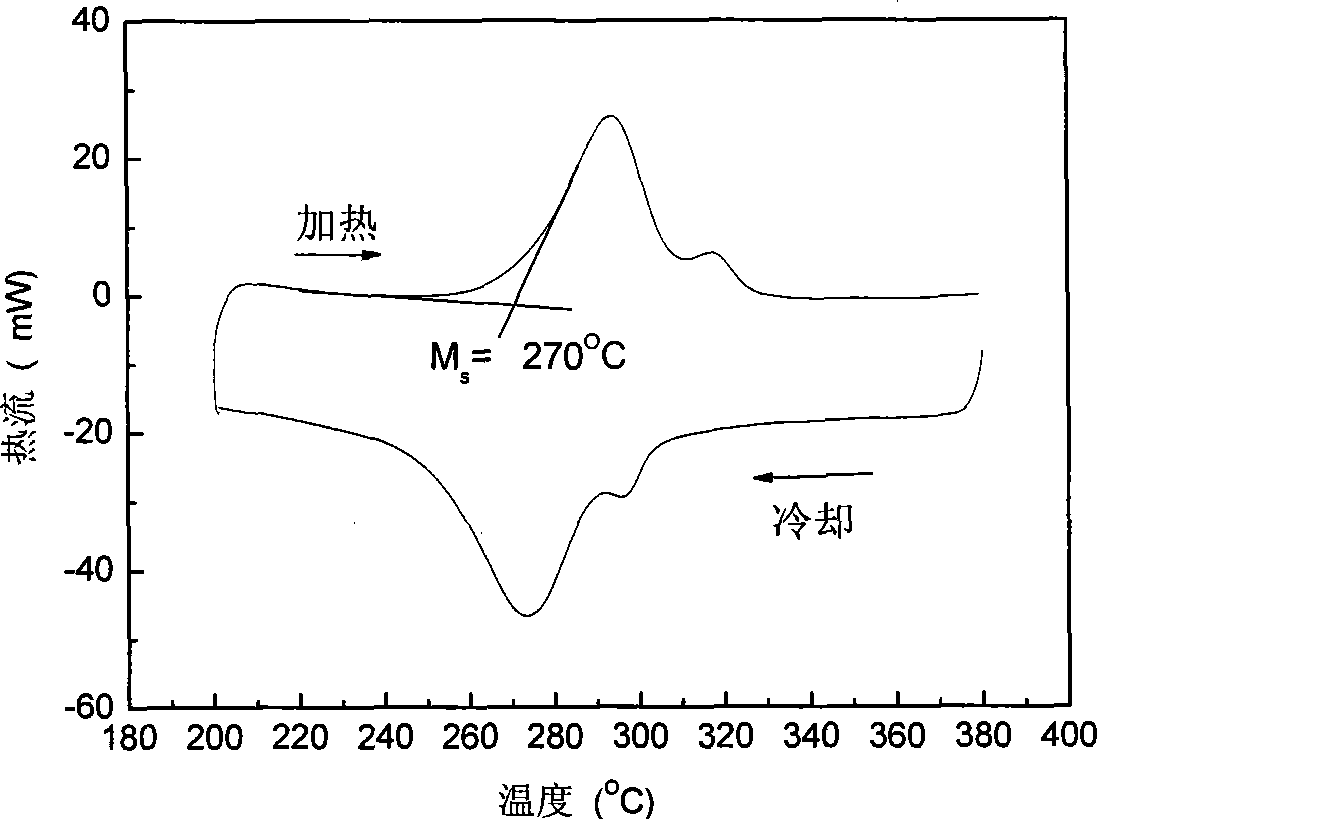

[0029] Embodiment 2: prepare Ni 43 co 7 mn 43 sn 7 alloy

[0030] (1) According to Ni 43 co 7 mn 43 sn 7 The atomic percent is nickel (Ni) with a purity of 99.9%, cobalt (Co) with a purity of 99.9%, manganese (Mn) with a purity of 99.9% and tin (Sn) with a purity of 99.9%;

[0031] (2) Put the nickel (Ni), cobalt (Co), manganese (Mn) and tin (Sn) raw materials weighed in the first step into a non-consumable vacuum electric arc furnace, and draw a vacuum so that the vacuum degree of the back reaches 2 ×10 -2 ~5×10 -3 Pa, then filled with high-purity argon to 500Pa, using high-temperature arc to smelt the raw material into Ni 43 co 7 mn 43 sn 7 button-shaped ingot;

[0032] (3) Prepare a rod-shaped ingot with a diameter of 10mm by using a vacuum suction casting device to obtain Ni 43 co 7 mn 43 sn 7 High temperature shape memory alloys.

[0033] Using the electric spark cutting method, cut a cuboid with a size of 2×2×3 from the nickel-cobalt-manganese-tin high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com