Preparation method of novel negative electrode contact material for solid oxide fuel cell

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of long-term stability and thermal cycle stability not guaranteed, high cost of precious metals, large usage of contact materials, etc. problem, to achieve the effect of good thermal cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the novel cathode contact material of the solid oxide fuel cell of the present invention comprises the following steps:

[0032] Step 1, be 5: 3: 2 to get La(NO) according to the metal ion mol ratio 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Ni (NO 3 ) 2 ·6H 2 O mixes to obtain metal nitrate;

[0033] Step 2, take PVA, make the molar ratio of PVA hydroxyl and all metal cations of metal nitrate in step 1 to be 1:4, mix PVA with distilled water to prepare a PVA aqueous solution with a mass fraction of 5%, heat the PVA aqueous solution and stir to PVA The aqueous solution is completely clarified; the storage container of the prepared PVA aqueous solution with a mass fraction of 5% is sealed to prevent water evaporation; the PVA aqueous solution is heated and stirred until the PVA aqueous solution is completely clarified. After it is fully swollen, adjust the temperature of the oil bath to 95°C, and continue to stir until it is completely clear; ...

Embodiment 2

[0038] The preparation method of the novel cathode contact material of the solid oxide fuel cell of the present invention comprises the following steps:

[0039] Step 1. Take La(NO) according to the molar ratio of metal ions as 5:3:2 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Ni (NO 3 ) 2 ·6H 2 O mixes to obtain metal nitrate;

[0040] Step 2, take PVA, make the molar ratio of PVA hydroxyl and all metal cations of metal nitrate in step 1 to be 1:4, mix PVA with distilled water to prepare a PVA aqueous solution with a mass fraction of 5%, heat the PVA aqueous solution and stir to PVA The aqueous solution is completely clarified; the prepared PVA aqueous solution with a mass fraction of 5% is covered with plastic wrap to prevent water evaporation; the process of heating and stirring the PVA aqueous solution until the PVA aqueous solution is completely clarified is the process of heating and stirring the PVA aqueous solution at 45 °C for 1 hour. , adjust the oil bath temperature ...

Embodiment 3

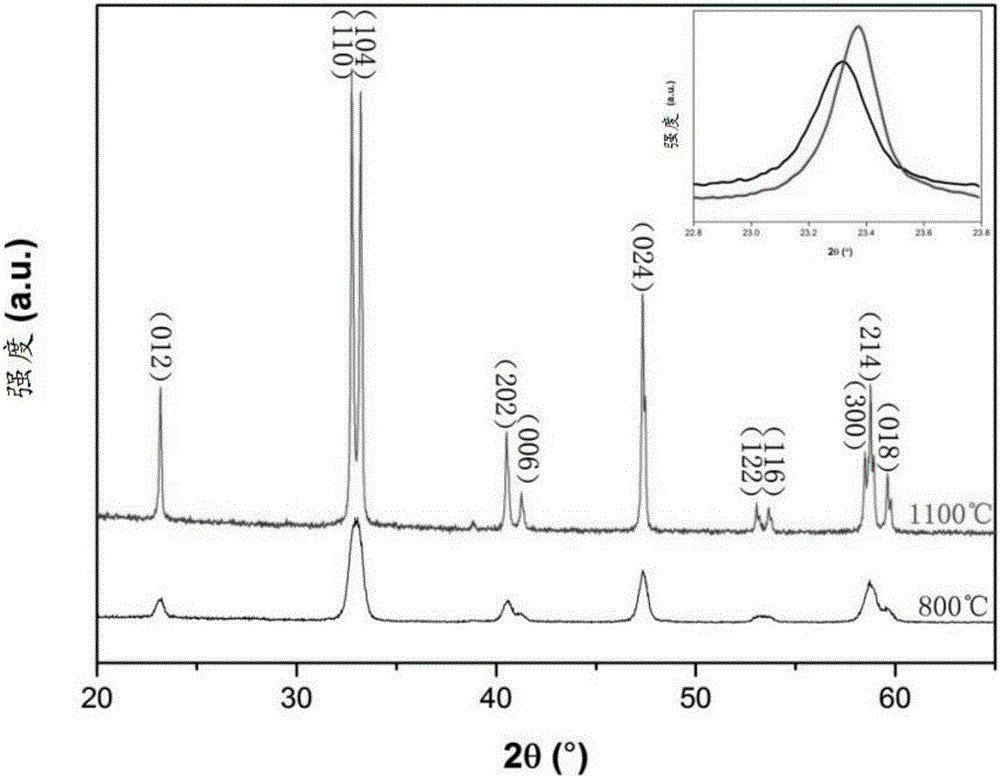

[0045] XRF analysis was performed on the coarse powder (1100 ℃ LCN) of the new cathode contact material for solid oxide fuel cells prepared in Example 1 and the fine powder (800 ℃ LCN) for the new cathode contact material for solid oxide fuel cells prepared in Example 1, and the powders were obtained. The chemical element ratios of La, Co, and Ni are shown in Table 1. X-ray diffraction analysis was performed on the two LCN powders, and the results were as follows figure 1 shown.

[0046] Table 3 Chemical element ratio in LCN powder

[0047]

[0048] Depend on figure 1 It can be seen that the powders obtained after holding at 800 °C and 1100 °C for 3 hours are all pure LCN powders. From the main diffraction peaks, it can be seen that the crystal structure of pure LCN belongs to the hexagonal crystal system. LCN still maintains a stable phase structure after being treated at a high temperature of 1100° C. and does not decompose, indicating that the LCN powder prepared by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com