Preparation method of spherical phase change microcapsule

A phase change microcapsule, spherical technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as poor compatibility, flow, corrosion, etc., achieve small particle size, high purity, and physical and chemical stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

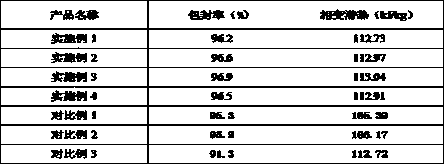

Examples

Embodiment 1

[0024] A preparation method of spherical phase-change microcapsules, the composition is by weight, comprising the following steps:

[0025] (1) Mix 2 parts of n-dodecyl alcohol, 1 part of beeswax, 2 parts of polyethylene glycol, 1 part of beesic acid, 1 part of lauric acid, 15 parts of cationic modified styrene, 5 parts of acrylonitrile, 1 part of acrylic acid and 1 part of tragacanth gum was mixed evenly to obtain solution A;

[0026] (2) Mix 0.5 parts of azobisisobutylamidine hydrochloride, 5 parts of sodium potassium stearate and 85 parts of deionized water, and stir for 10 minutes to obtain solution B;

[0027] (3) Add solution A to solution B, and pre-emulsify at a speed of 500r / min for 30min;

[0028] (4) Transfer to an ultrasonic cell disruptor, under the protection of an ice-water bath, ultrasonically disperse for 10 minutes under the conditions of a power of 200W and a time interval of 2s;

[0029] (5) Transfer to a three-necked flask equipped with a reflux condense...

Embodiment 2

[0033] A preparation method of spherical phase-change microcapsules, the composition is by weight, comprising the following steps:

[0034] (1) Mix 3 parts of n-dodecyl alcohol, 1.5 parts of beeswax, 3 parts of polyethylene glycol, 1.5 parts of beesic acid, 1.5 parts of lauric acid, 17 parts of cationic modified styrene, 6 parts of acrylonitrile, 1.5 parts of acrylic acid and 1.5 parts of propylene glycol were mixed uniformly to obtain solution A;

[0035] (2) Mix 0.7 parts of azobisisobutylamidine hydrochloride, 6 parts of sodium potassium stearate and 90 parts of deionized water, and stir for 12 minutes to obtain solution B;

[0036] (3) Add solution A to solution B, and pre-emulsify at a speed of 550r / min for 35 minutes;

[0037] (4) Transfer to an ultrasonic cell disruptor, under the protection of an ice-water bath, ultrasonically disperse for 12 minutes under the conditions of a power of 220W and a time interval of 3s;

[0038] (5) Transfer to a three-necked flask equip...

Embodiment 3

[0042] A preparation method of spherical phase-change microcapsules, the composition is by weight, comprising the following steps:

[0043] (1) Mix 4 parts of n-dodecyl alcohol, 1.5 parts of beeswax, 3 parts of polyethylene glycol, 1.5 parts of beesic acid, 2 parts of lauric acid, 18 parts of cationic modified styrene, 6 parts of acrylonitrile, 1.5 parts of acrylic acid and 1.5 parts of glycerin were mixed evenly to obtain solution A;

[0044] (2) Mix 0.8 parts of azobisisobutylamidine hydrochloride, 7 parts of sorbitan monostearate and 95 parts of deionized water, and stir for 13 minutes to obtain solution B;

[0045] (3) Add solution A to solution B, and pre-emulsify at a speed of 550r / min for 35 minutes;

[0046] (4) Transfer to an ultrasonic cell disruptor, under the protection of an ice-water bath, ultrasonically disperse for 13 minutes under the conditions of a power of 230W and a time interval of 3s;

[0047] (5) Transfer to a three-necked flask equipped with a reflux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com