Metal phase change microcapsule with thermal expansion cavity and preparation method of metal phase change microcapsule

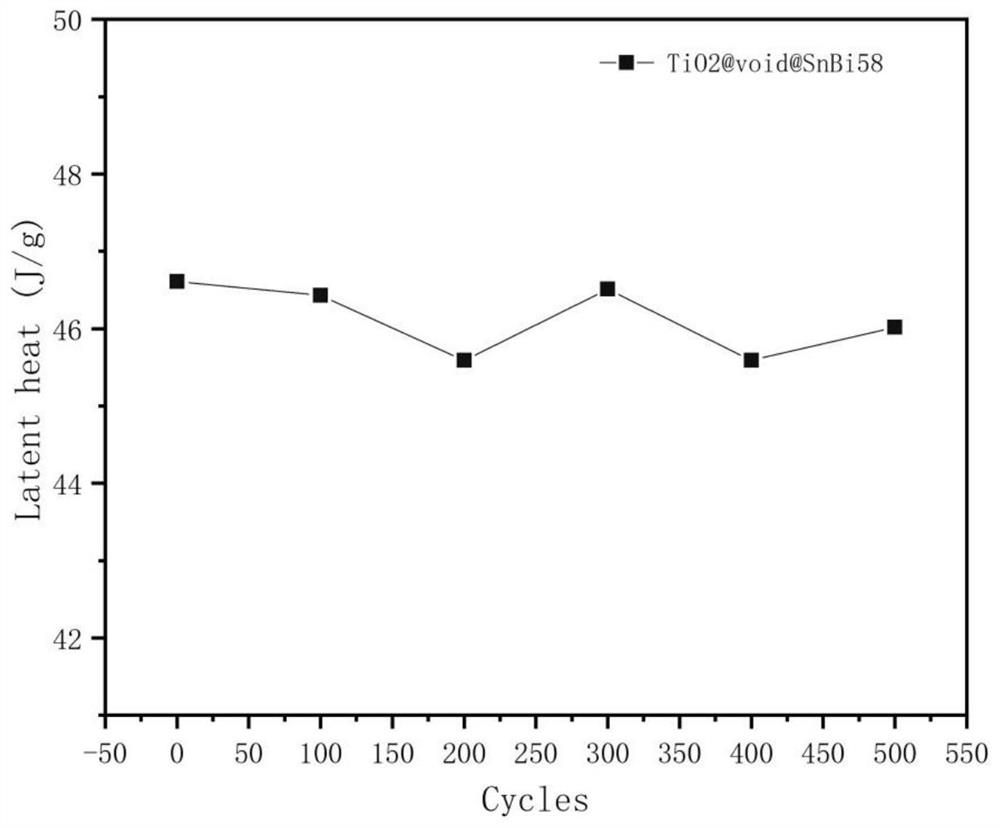

A technology of metal phase change and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of poor thermal cycle performance of metal microcapsules and easy rupture of metal microcapsules, and achieve a breakthrough in preparation technology Bottleneck, improving the level of phase change energy storage technology, and improving the effect of thermal cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the metal phase change microcapsule with thermal expansion cavity of the present embodiment comprises the following steps:

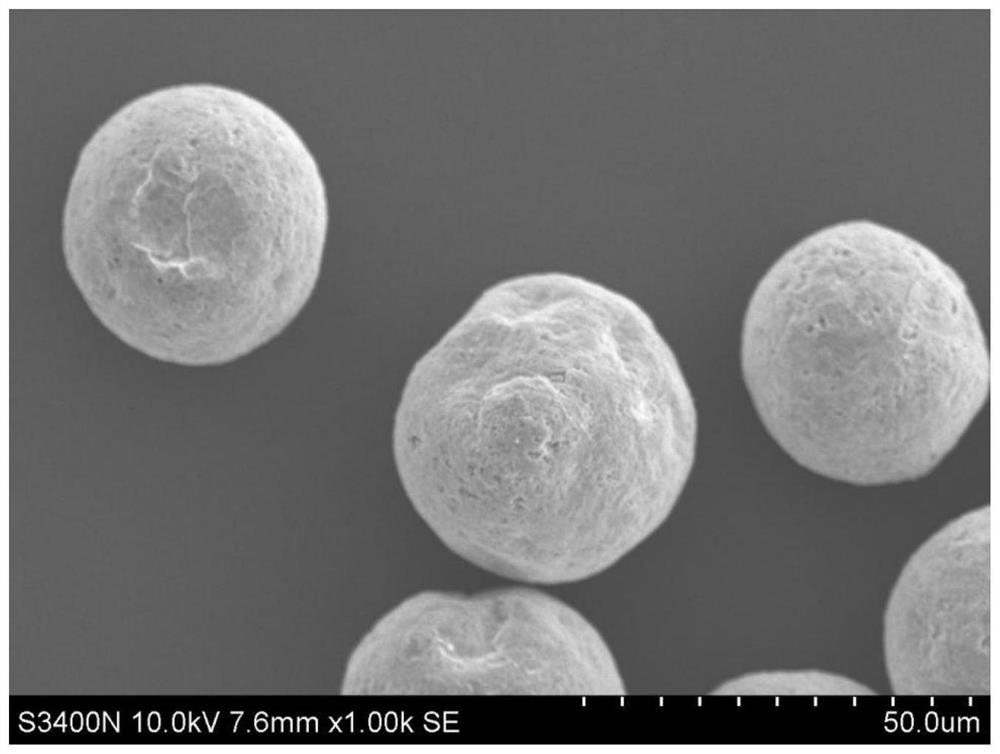

[0034] S1: Weigh 6g of spherical metal alloy powder (SnBi58), and evenly disperse it in 100ml of deionized water to obtain a dispersion; then add 0.55g of methacrylic acid (MAA) monomer, and then add 0.02g of ammonium persulfate as an initiator , under the power of 200w, ultrasound assists the interfacial polymerization reaction on the surface of the alloy particles, reacts for 30min, and obtains pre-microcapsules, uses deionized water to wash the pre-microcapsules three times, and then filters them with suction, and dries at 80°C for 5h to obtain PMMA / SnBi58 phase change microcapsules;

[0035] S2: preparation concentration is the ammonium fluorotitanate aqueous solution of 100g / L and the boric acid aqueous solution that concentration is 100g / L; Get the PMMA / SnBi58 phase change microcapsule that 5g step S1 obtains, add ...

Embodiment 2

[0039] The preparation method of the metal phase change microcapsule with thermal expansion cavity of the present embodiment comprises the following steps:

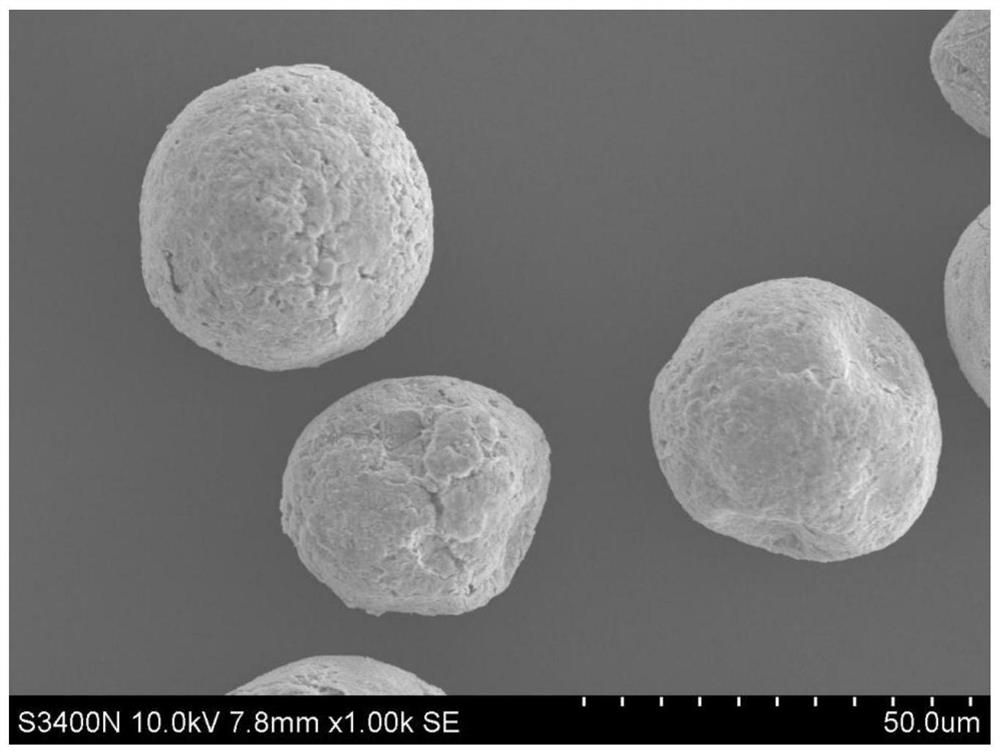

[0040]S1: Weigh 6g of spherical metal alloy powder (SnBi58), and evenly disperse it in 100ml of deionized water to obtain a dispersion; add 1g of methacrylic acid (MAA) monomer, and then add 0.02g of benzoyl peroxide as an initiator , under the power of 200w, ultrasound assists the interfacial polymerization reaction on the surface of the alloy particles, reacts for 30min, and obtains pre-microcapsules, uses deionized water to wash the pre-microcapsules three times, and then filters them with suction, and dries at 80°C for 5h to obtain PMMA / SnBi58 phase change microcapsules;

[0041] S2: preparation concentration is the ammonium fluorotitanate aqueous solution of 100g / L and the boric acid aqueous solution that concentration is 100g / L; Get the PMMA / SnBi58 phase change microcapsule that 5g step S1 obtains, add 0.5g surfact...

Embodiment 3

[0045] The preparation method of the metal phase change microcapsule with thermal expansion cavity of the present embodiment comprises the following steps:

[0046] S1: Weigh 6g of spherical metal alloy powder (SnBi58), and evenly disperse it in 100ml of deionized water to obtain a dispersion; add 2g of methacrylic acid (MAA) monomer, and then add 0.02g of benzoyl peroxide as an initiator , under the power of 200w, ultrasound assists the interfacial polymerization reaction on the surface of the alloy particles, reacts for 30min, and obtains pre-microcapsules, uses deionized water to wash the pre-microcapsules three times, and then filters them with suction, and dries at 80°C for 5h to obtain PMMA / SnBi58 phase change microcapsules;

[0047] S2: preparation concentration is the ammonium fluorotitanate aqueous solution of 100g / L and the boric acid aqueous solution that concentration is 100g / L; Get the PMMA / SnBi58 phase change microcapsule that 5g step S1 obtains, add 0.5g surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com