Production method for thin specification Q370qE steel plate

A production method, q370qe technology, applied in the field of low-alloy structural steel production, can solve the problems of increasing the difficulty of plate shape control, complex manufacturing process, high alloy cost, etc., to achieve simple and controllable manufacturing process, low alloy cost, and less precious metal content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

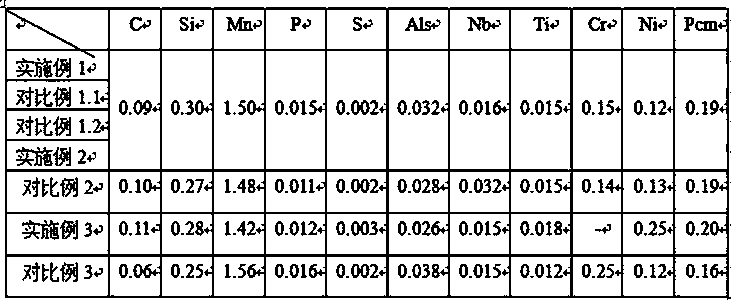

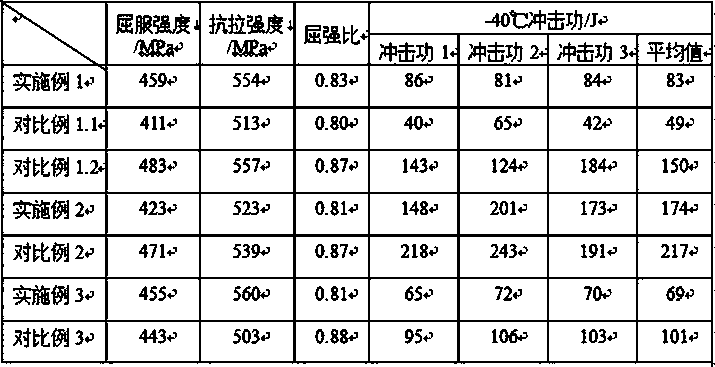

Embodiment 1

[0015] Embodiment 1: The thickness of the steel plate is 8mm. The heating temperature of the slab is 1230°C, the final rolling temperature of the first stage is 825°C, the second stage is rolled for 2 passes, the rolling temperatures are 678°C and 628°C, and the pass reduction rates are 8.9% and 7.8% respectively . Air-cool to room temperature after rolling.

Embodiment 2

[0018] Embodiment 2: The thickness of the steel plate is 10mm. The heating temperature of the slab is 1220°C, the final rolling temperature of the first stage is 840°C, the second stage is rolled for 2 passes, the rolling temperatures are 675°C and 632°C, and the pass reduction rates are 10.2% and 8.6% respectively . Air-cool to room temperature after rolling.

Embodiment 3

[0020] Embodiment 3: The thickness of the steel plate is 6mm. The slab heating temperature is 1230°C, the final rolling temperature in the first stage is 820°C, the second stage is rolled 1 pass, the rolling temperature is 650°C, and the pass reduction rate is 14.3%. Air-cool to room temperature after rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com