Preparation method of high-strength high-plasticity Ni-W-X alloy

A high-plasticity and high-strength technology, applied in the field of high-strength and high-plasticity Ni-W-X alloy preparation, can solve problems such as high cost and complex preparation process, and achieve the effect of simple steps and improved as-cast mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a high-strength and high-plasticity Ni-W-X alloy. The raw materials of the casting alloy include nickel-tungsten binary master alloy, Ni element and X element;

[0034] The atomic percentage of tungsten in the nickel-tungsten binary master alloy is 11%;

[0035] The purity of the Ni elemental substance is not less than 99.5%;

[0036] The purity of the X elemental substance is not less than 99.5%, and X is Al;

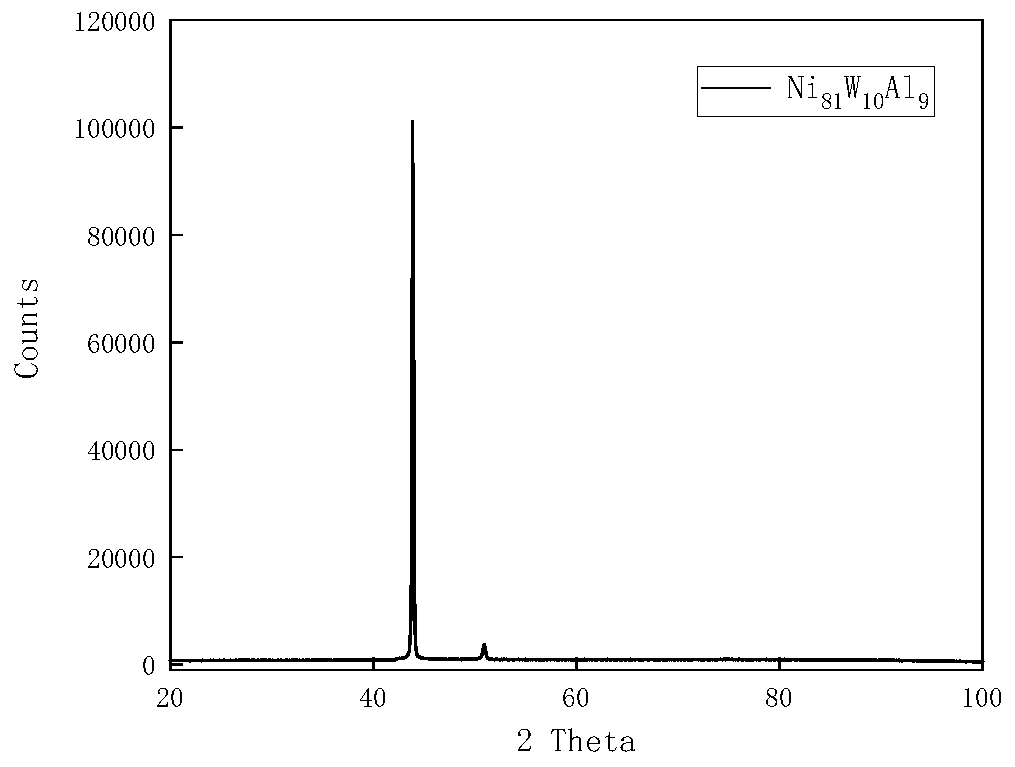

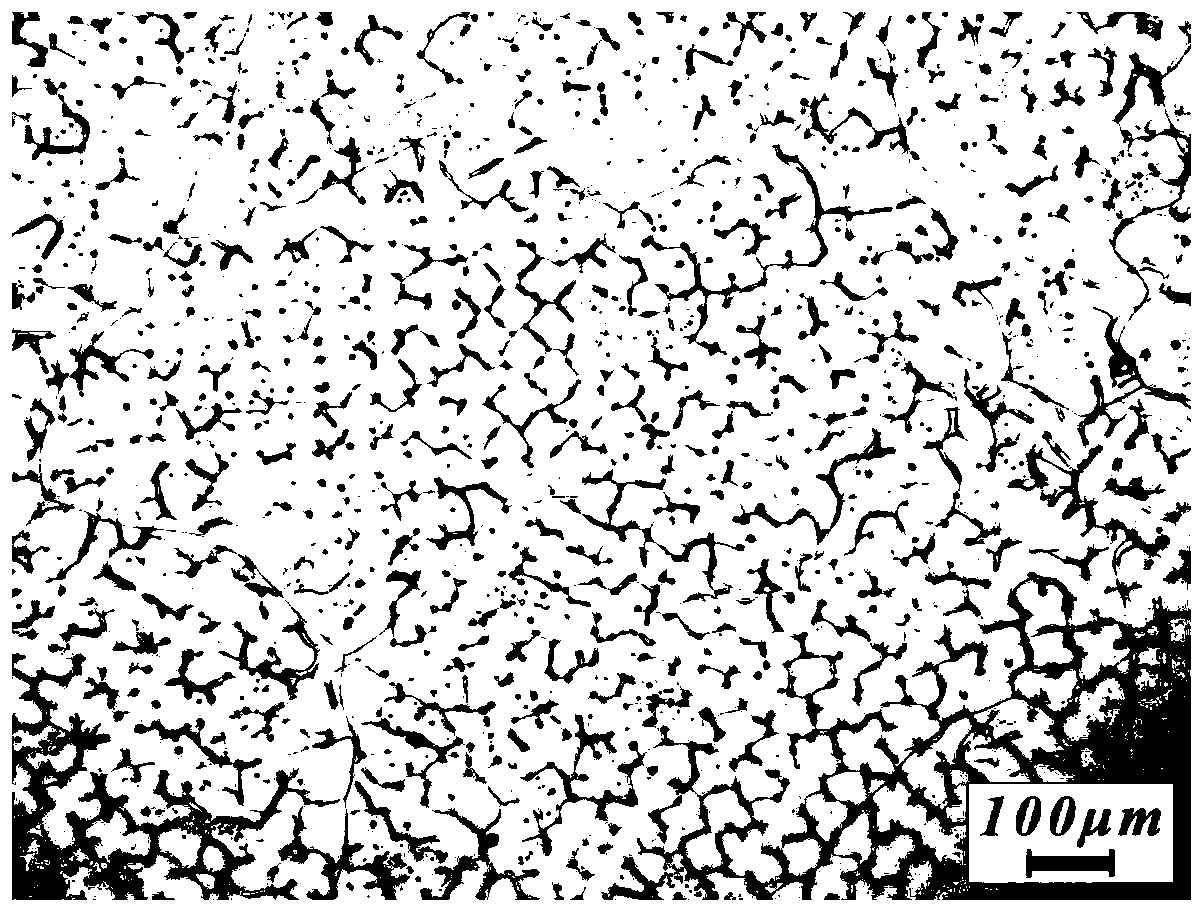

[0037] The atomic percentage of W in this cast alloy was 10 atomic %, the atomic percentage of Al was 9 atomic %, and the balance was Ni.

[0038] Prepare the atomic ratio as Ni 81 W 10 al 9 Alloy, the specific steps are as follows:

[0039] Step 1: Select Ni-11W master alloy with 11% W atomic percentage, nickel and aluminum with a purity of 99.5% as raw materials, and use 100# silicon carbide sandpaper to polish the Ni-11W master alloy and Ni and Al to obtain a clean The raw materials were ultrasonically cleaned with acetone, and th...

Embodiment 2-18

[0053] Examples 2-18 adopt the same process route as Example 1, only the alloy raw materials and components are different, and the mechanical properties of the tested alloys are shown in Table 1.

[0054] Table 1 Example 2-18 alloy composition and performance table

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com