Method for preparing nano titanium dioxide photocatalyst and its product

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation and other directions, can solve the problems of complex heat treatment process, difficult industrialized production, high production cost, etc., and achieves easy preparation process. The effect of control, clever coating and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Features: Select S element as the inner doping element, calcium phosphate as the outer coating compound

[0036] ①. Add 550ml of distilled water dropwise to 500ml of titanium tetrachloride at a certain speed, and the titanium tetrachloride is slowly hydrolyzed into an orange-yellow transparent liquid;

[0037] 2. Add 8g of polyvinyl alcohol to the orange-yellow transparent liquid formed in step 1, keep the temperature at 70°C and stir for 1 hour;

[0038] ③. Slowly drop 1 gram of sulfuric acid into the liquid formed in step 2, slowly stir for 1 hour, and keep the temperature at 50 °C;

[0039] ④. Add the liquid formed in step 3 into 1050ml of distilled water at 75°C, and stir at a certain speed at the same time. After white crystals are formed, keep the temperature of 90°C, continue to stir and ripen for 2 hours;

[0040] ⑤. Use 25% (W / W) sodium bicarbonate titration to adjust the pH of the liquid formed in step 4 to 7, then add 100 ml of 4% (W / W) calcium chloride solu...

Embodiment 2

[0045] Features: Sn is used as the inner doping element, and alumina is used as the outer cladding compound.

example 2

[0046] The difference between the preparation process of Example 2 and Example 1 is that the elements selected for the doping treatment in step 3 are different, the surface outer covering formed in step 5 is different, and the rest are the same;

[0047] Steps ① and ② are omitted;

[0048]Step 3. Under the condition of slow stirring, slowly drop 50ML of SnCL with a concentration of 0.4% into the liquid formed in step 2, keep the temperature at 60°C, and stir for 2 hours;

[0049] Step ④ is omitted;

[0050] Step 5. Use 25% (w / w) sodium bicarbonate titration to adjust the pH of the reactant formed in step 4 to 7.5, and then add 200 ml of 5% (w / w) sodium aluminate solution, 5% (w / w) 200ml of dilute sulfuric acid solution of 200ml, stir at a constant speed, properly heat and keep the temperature at 100℃ for 1 hour, the surface of the white crystal forms an alumina coating;

[0051] Step ⑥⑦ is omitted;

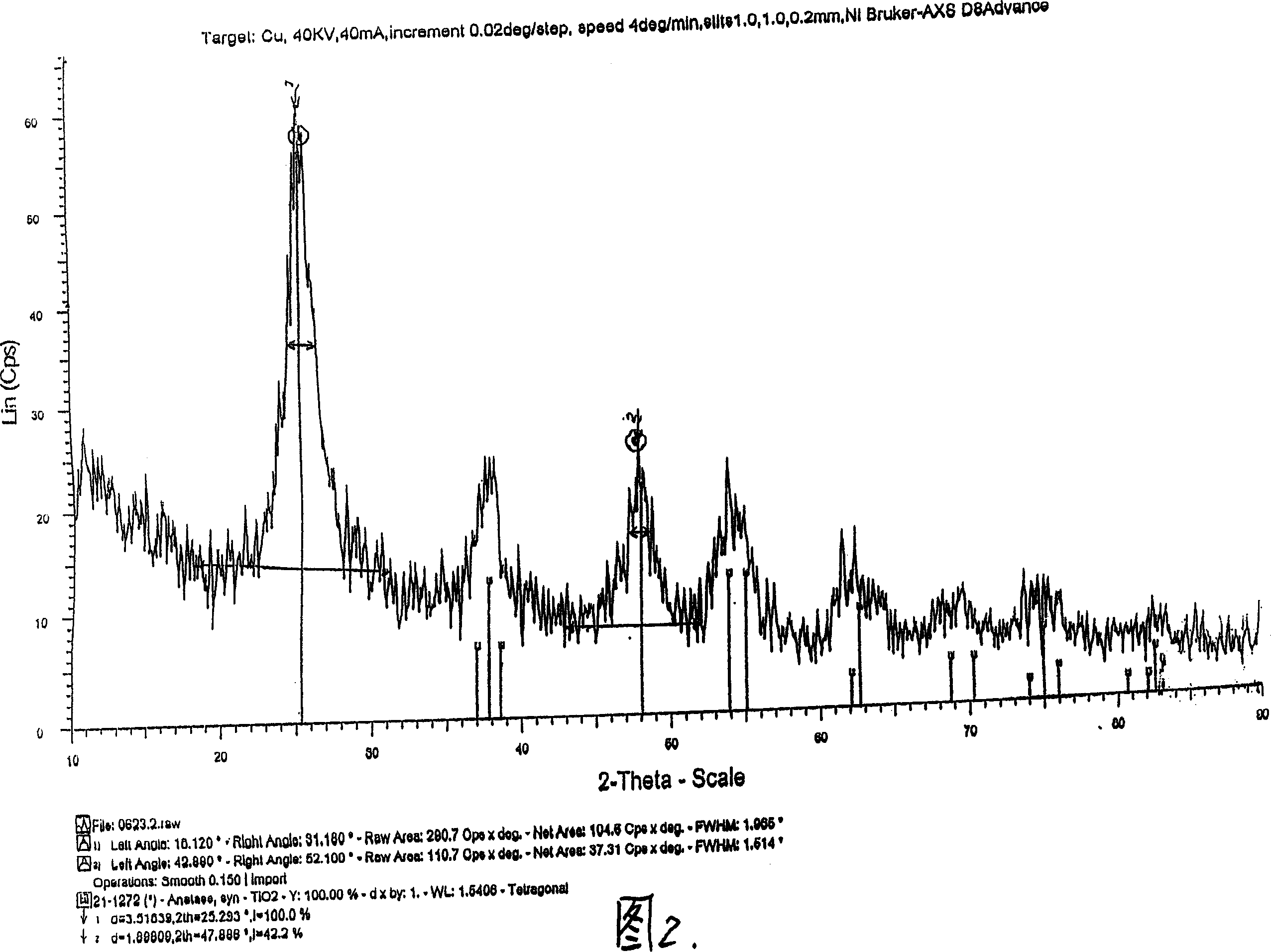

[0052] After the steps ①-⑦, what is obtained in Example 2 is an anatase na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com