Preparation method of solar selective-absorption thin film with spinel structure

A technology of spinel structure and selective absorption, which can be applied to radiation-absorbing coatings, devices for coating liquids on surfaces, and special surfaces, etc. It can solve the problems of inability to highlight the hyperspectral selectivity of thin films, cumbersome preparation processes, and experimental conditions. Higher requirements and other issues, to achieve the effect of improving light-to-heat conversion efficiency, simple and controllable process, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Weigh 2.42gCu(NO 3 ) 2 ·3H 2 O, 2.37gMn(Ac) 2 4H 2 O, 0.97gCo(NO 3 ) 2 ·6H 2 O was placed in a 100ml beaker, and 58ml of absolute ethanol was added and stirred to dissolve for 20 minutes. The total molar concentration of metal ions was 0.40mol / L.

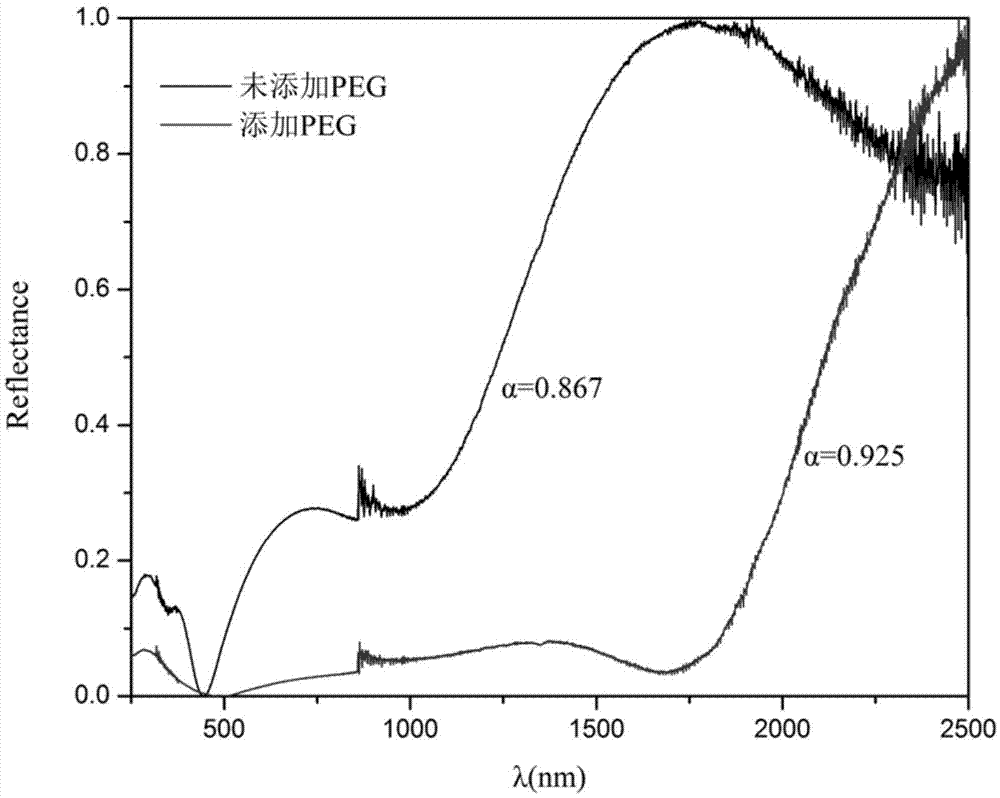

[0022] 2. Add 4.9 g of citric acid monohydrate to the above solution, the molar ratio of citric acid to metal ions is 1:1, stir at room temperature for 1 hour, then add polyethylene glycol 200 to 3.73 g, the mixture of polyethylene glycol 200 and citric acid The molar ratio was 0.8:1, and the stirring was continued at room temperature for 1 hour, and finally 0.61 g of hydroxypropyl cellulose was slowly added and magnetically stirred for 4 hours to obtain a film-forming sol.

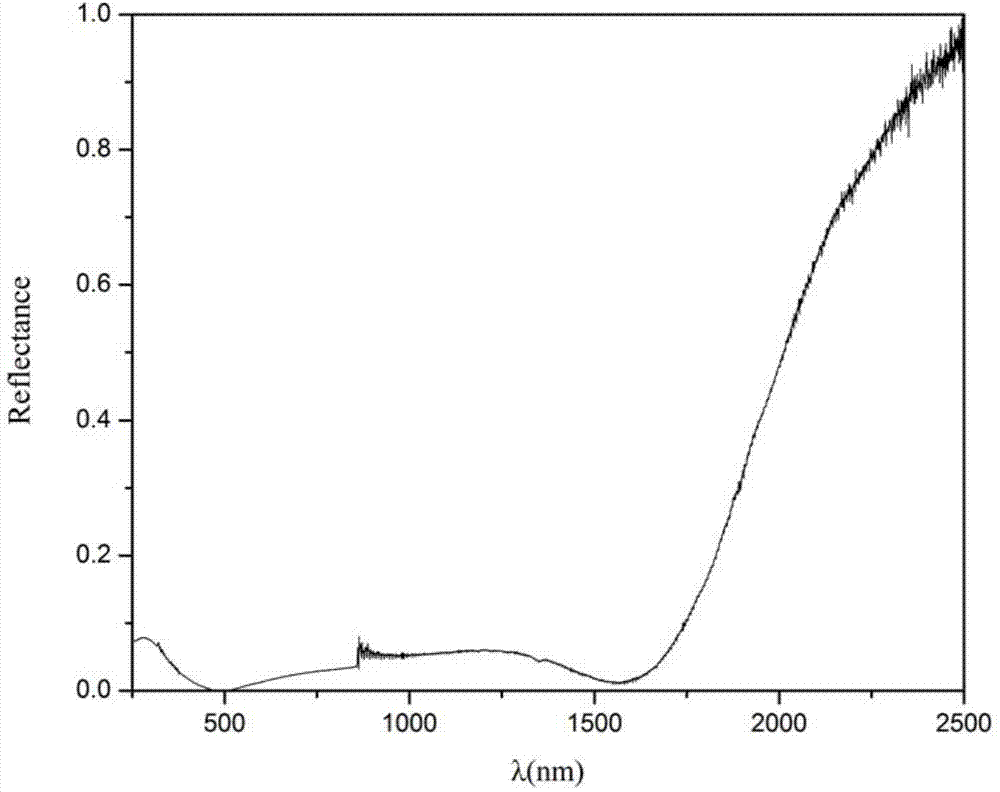

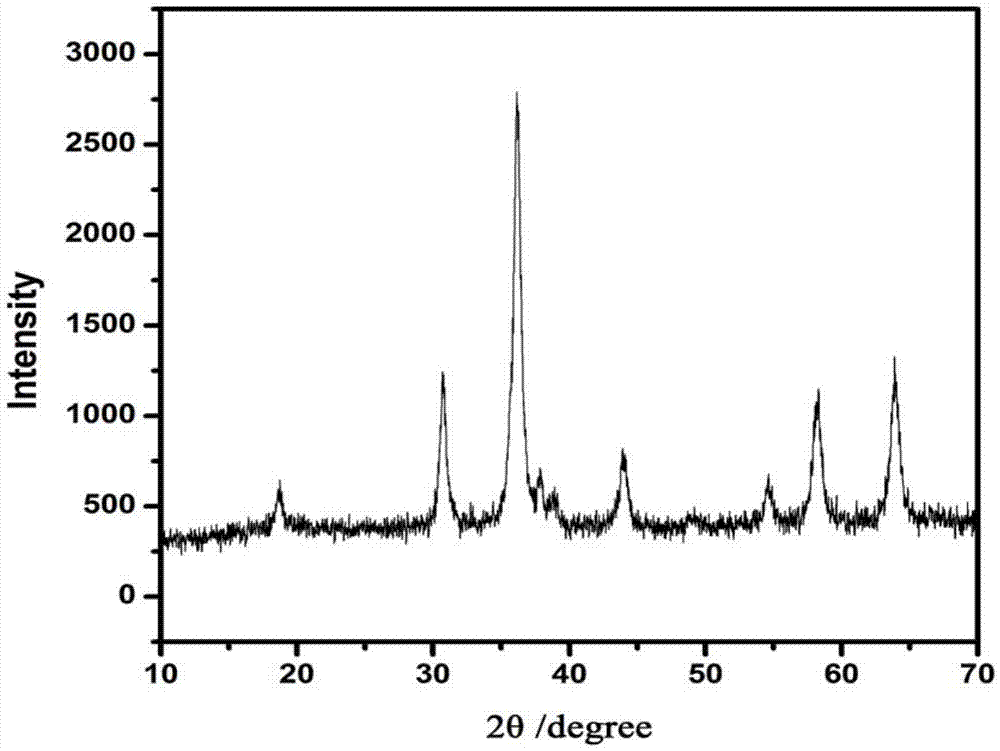

[0023] 3. Degrease the stainless steel sheet with a degreasing solution, then ultrasonically wash it with ethanol and acetone for 15 minutes, rinse it with deionized water, and dry it for later use. Using the dipping and pulling method on a co...

Embodiment 2

[0026] 1. Weigh 2.42gCu(NO 3 ) 2 ·3H 2 O, 2.37gMn(Ac) 2 4H 2 O, 0.97gCo(NO 3 ) 2 ·6H 2 O was placed in a 100ml beaker, and 78ml of absolute ethanol was added to stir and dissolve for 20 minutes. The total molar concentration of metal ions was 0.30mol / L.

[0027] 2. Add 4.9g of citric acid monohydrate to the above solution, the molar ratio of citric acid to metal ions is 1:1, after stirring at room temperature for 1 hour, add polyethylene glycol 200 to be 4.66g, the mixture of polyethylene glycol 200 and citric acid The molar ratio was 1:1, and the stirring was continued at room temperature for 1 hour, and finally 0.78 g of hydroxypropyl cellulose was slowly added and magnetically stirred for 4 hours to obtain a film-forming sol.

[0028] 3. Degrease the aluminum sheet with a degreasing solution, then ultrasonically wash it with ethanol and acetone for 15 minutes, rinse with deionized water, and dry it for later use. Using dipping and pulling method on constant speed pu...

Embodiment 3

[0032] 1. Weigh 1.71g Cu(Cl) 2 2H 2 O, 2.37gMn(Ac) 2 4H2 O, 0.79gCo(Cl) 2 ·6H 2 O was placed in a 100ml beaker, and 70ml of absolute ethanol was added to stir and dissolve for 20 minutes. The total molar concentration of metal ions was 0.33mol / L.

[0033] 2. Add 5.88g of citric acid monohydrate to the above solution, the molar ratio of citric acid to metal ion is 1.2:1, stir at room temperature for 1 hour, add polyethylene glycol 200 to 6.71g, the mixture of polyethylene glycol 200 and citric acid The molar ratio was 1.2:1, and stirring was continued at room temperature for 1 hour, and finally 0.74 g of ethyl cellulose was slowly added and magnetically stirred for 4 hours to obtain a film-forming sol.

[0034] 3. Degrease the aluminum sheet with a degreasing solution, then ultrasonically wash it with ethanol and acetone for 15 minutes, rinse with deionized water, and dry it for later use. Using dipping and pulling method on the constant speed pulling machine, use the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com