Preparation method for visible light photocatalyst prepared by CdS quantum dot sensitization Zn1-xCdxs and photodecomposition of water into hydrogen

A zn1-xcdxsx, quantum dot sensitization technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low activity of visible light photocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

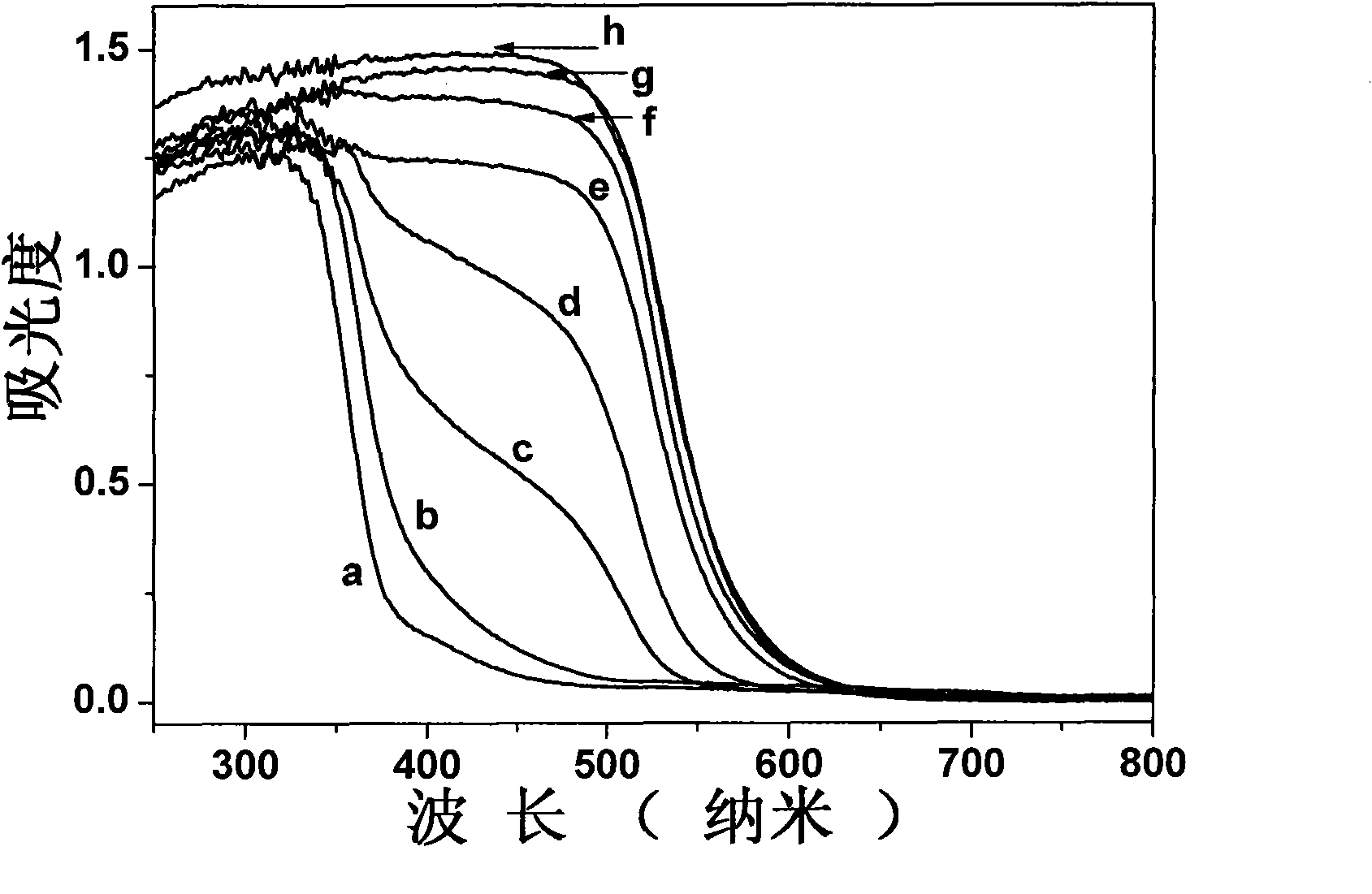

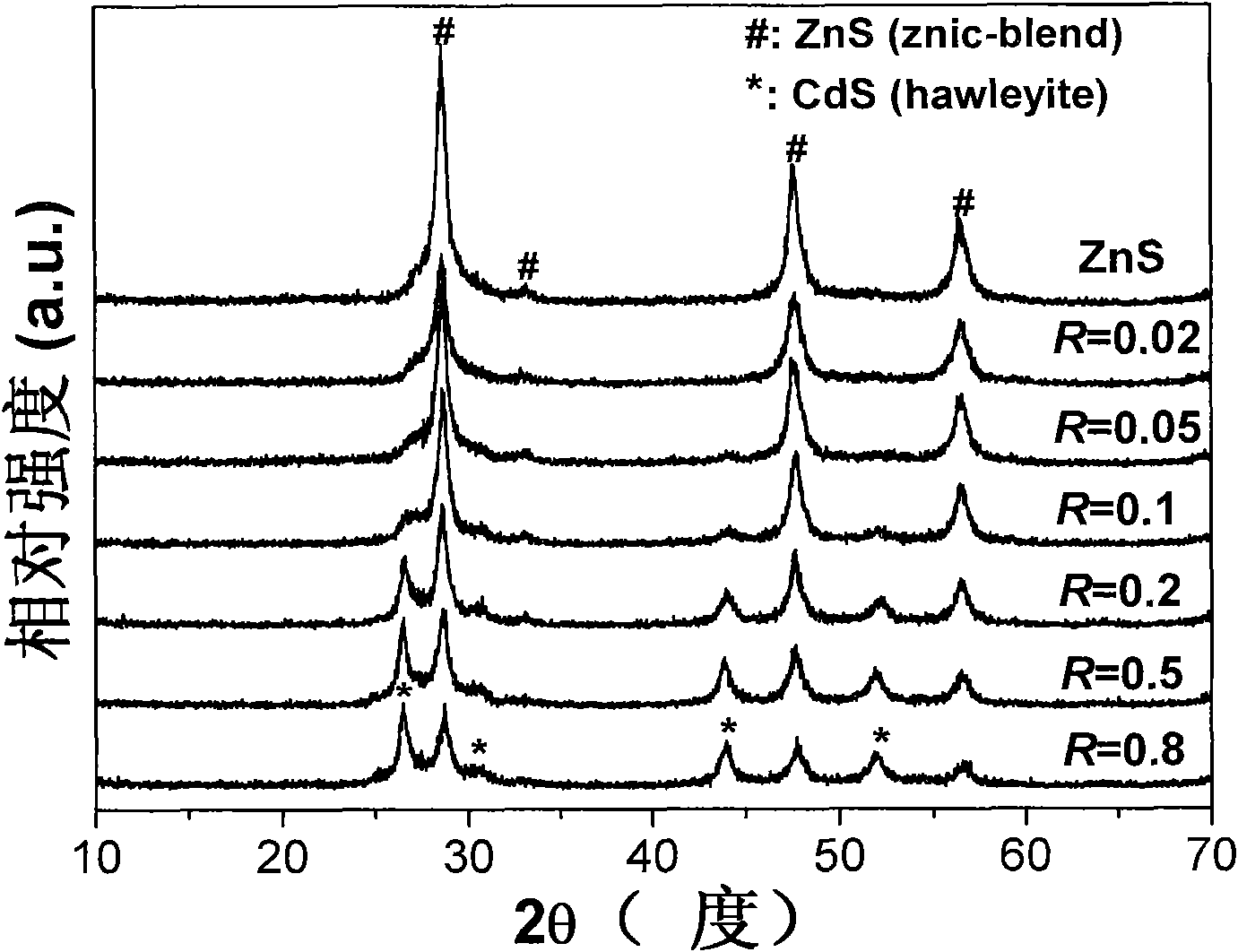

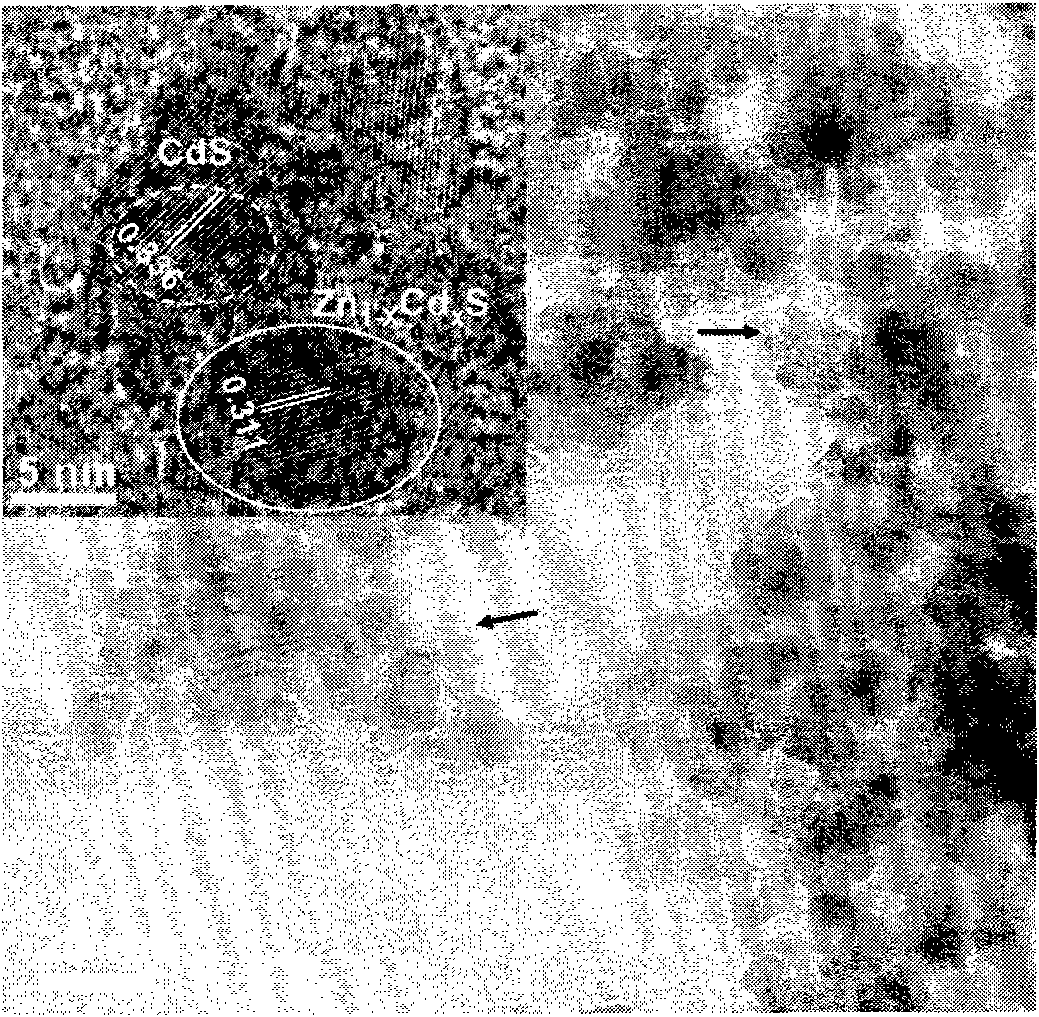

[0033] Preparation of CdS quantum dots sensitized Zn 1-x Cd x Sx≤0.02 solid solution photocatalyst

[0034] Firstly, ZnS nanoparticles were prepared, and then CdS quantum dots were deposited on Zn by cation exchange hydrothermal method. 1-x Cd x Sx≤0.02 solid solution surface, the detailed experimental process is as follows: first, zinc nitrate is used as zinc source, thiourea is used as sulfur source, and ZnS nanoparticle precursor is prepared by hydrothermal method. Dissolve 4 mmol of zinc nitrate hexahydrate and 60 mmol of thiourea in 80 ml of deionized water with stirring. After stirring at room temperature for 30 minutes, the mixed solution was transferred to a 100 ml polytetrafluoroethylene reactor. After sealing, the reactor was heated to 140° C. and kept at this temperature for 12 hours. After the reactor was cooled to room temperature, the white product was collected and washed with deionized water and ethanol in sequence, and then the powder was dried in a drying...

Embodiment 2

[0043] In order to prove that the CdS quantum dot pair improves the Zn 1-x Cd x Effect of Sx≤0.02 solid solution photocatalyst on visible light photocatalytic water splitting hydrogen production activity, comparing CdS nanoparticles sensitized Zn with different grain sizes 1-x Cd x The activity of Sx≤0.02 solid solution photocatalyst (see Table 1). The results showed that Zn alone 1-x Cd x S x ≤ 0.02 solid solution has weak activity, when in Zn 1-x Cd x After a certain amount of CdS is loaded on the surface of the solid solution with Sx≤0.02, the visible light activity of the product is obviously enhanced. But as the size of CdS particles gradually increased, the activity of the samples gradually decreased. This is because only under the influence of the quantum size effect, the position of the valence band and the conduction band of the CdS quantum dots can facilitate the transfer of photogenerated electrons, thereby improving the photocatalytic activity of the product...

Embodiment 3

[0045] In order to test the effect of hydrothermal time on the photocatalytic activity of the sample, in the cation exchange hydrothermal process, the hydrothermal temperature was fixed at 140°C. Except for the different hydrothermal time, other reaction conditions such as: the amount of ZnS precursor, the volume of cadmium nitrate solution And reaction system etc. are all identical with embodiment 1. The results show that the samples prepared in 0-1 hours have poor crystallization due to the short hydrothermal time, and the hydrogen production activity of visible light photocatalytic decomposition of water is very low. With the prolongation of hydrothermal time, the photocatalytic activity of the samples gradually increased. When the hydrothermal time was increased to 8 hours, the photocatalytic activity of the sample increased significantly, usually the higher the crystallinity, that is to say the fewer surface and bulk defects, resulting in a decrease in the recombination p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com